Moisture absorbing and quick-dry machine washable wool worsted fabric and production method thereof

A worsted fabric, moisture-absorbing and quick-drying technology, applied in weaving, dyeing, textiles and papermaking, etc., can solve the problems of inability to reach wool fiber, limit the application of wool fiber, and not wrinkle-resistant, so as to expand the level and scope of application, Good promotion and application value, stable and lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

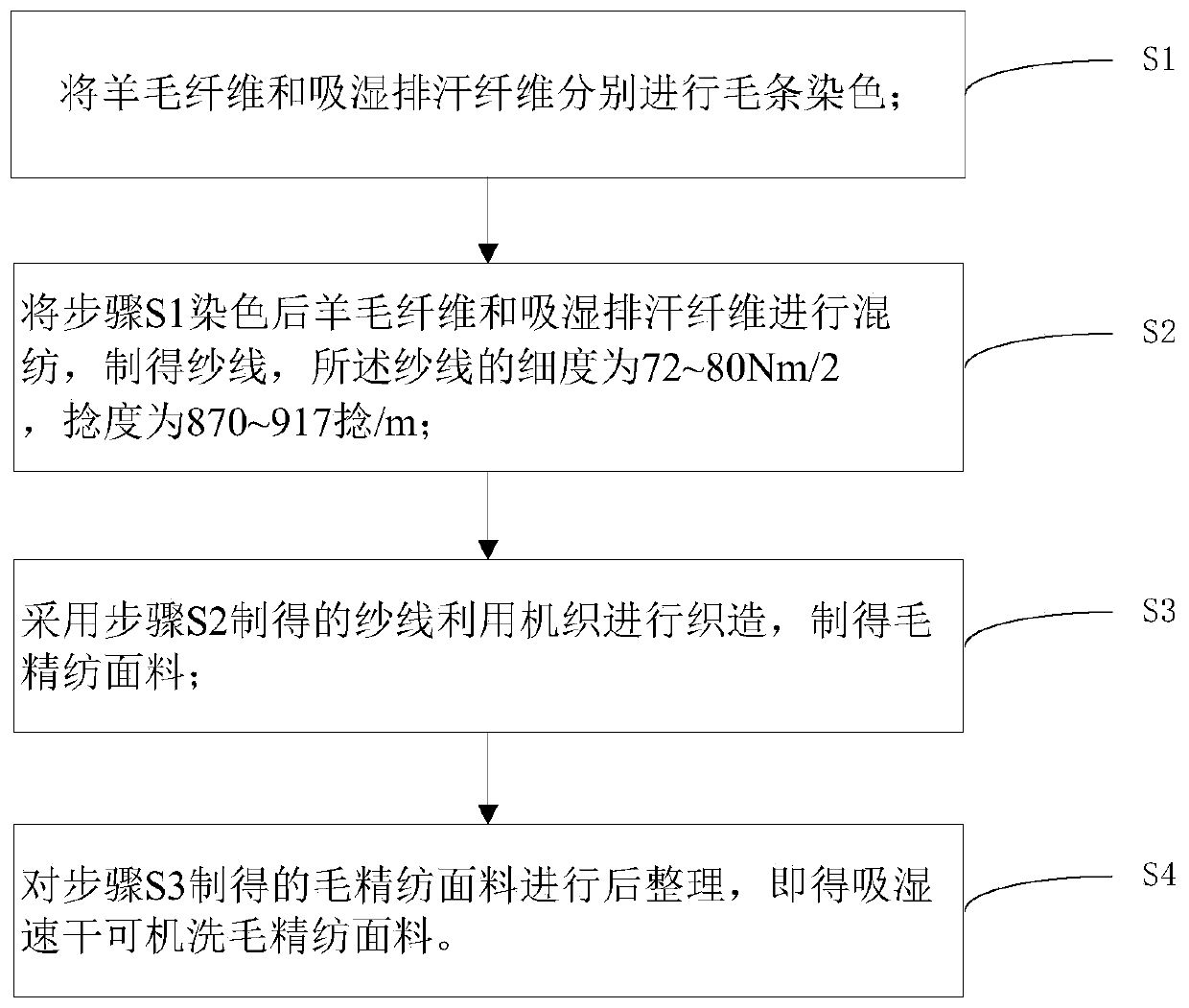

[0061] as attached figure 1 Shown, a kind of production method of moisture-absorbing and quick-drying machine-washable worsted fabric comprises the following steps:

[0062] S1, the wool fiber and the moisture-absorbing and sweat-wicking fiber are respectively carried out top dyeing, the moisture-wicking and sweat-wicking fiber is coolmax fiber, and the coolmax fiber is a polyethylene terephthalate (PET) fiber with a special-shaped section; the weight percentage is as follows: 80% wool fiber, 20% coolmax fiber, the fineness of wool fiber is 16-20μm, and the length is 70-80mm; the fineness of coolmax fiber is 2D, and the length is 70mm;

[0063] Among them, top dyeing includes wool fiber dyeing and moisture-wicking fiber dyeing;

[0064] Wool fiber dyeing involves the following steps:

[0065] 101. Add Lannasol Black CE-R, Abaig B and Yuanmingfen to the dyeing bathtub, adjust the pH value to 4 with acetic acid, and the leveling agent is Abaig B;

[0066] 102. Dip the wool fi...

Embodiment 2

[0096] as attached figure 1 Shown, a kind of production method of moisture-absorbing and quick-drying machine-washable worsted fabric comprises the following steps:

[0097] S1. Dye the wool fiber and the moisture-absorbing and perspiration-wicking fiber respectively. The moisture-absorbing and perspiration-wicking fiber is coolpuls fiber. Coolpuls fiber is a kind of polyester fiber, which is a combination of PET and special polymer. Ten" shape; the weight percentage is as follows: wool fiber 85%, coolpuls fiber 15%; the fineness of wool fiber is 16-20μm, and the length is 70-80mm; the fineness of coolpuls fiber is 3D, and the length is 90mm.

[0098] Among them, top dyeing includes wool fiber dyeing and moisture-wicking fiber dyeing;

[0099] Wool fiber dyeing involves the following steps:

[0100] 101. Add Lannasol Black CE, Abaiger LTD and Yuanming powder into the dyeing bathtub, adjust the pH value to 5 with acetic acid, and the leveling agent is Abaiger B;

[0101] 102...

Embodiment 3

[0131] as attached figure 1 Shown, a kind of production method of moisture-absorbing and quick-drying machine-washable worsted fabric comprises the following steps:

[0132] S1. Dyeing the wool fiber and the moisture-absorbing and sweat-wicking fiber respectively, wherein the percentage by weight is as follows: 82% of the wool fiber and 18% of the moisture-wicking and sweat-wicking fiber, the fineness of the wool is 16-20 μm, and the length is 70-80 mm; The moisture-wicking fiber has a fineness of 2.5D and a length of 80mm.

[0133] Among them, top dyeing includes wool fiber dyeing and moisture-wicking fiber dyeing;

[0134] Wool fiber dyeing involves the following steps:

[0135] 101. Add Lannasol blue CE, leveling agent Abaig B and Yuanming powder into the dyeing bathtub, and adjust the pH value to 4.5 with acetic acid, wherein the leveling agent is Abaig B;

[0136] 102. Dip the wool fiber into the dyeing tub in step 101 at a temperature of 25°C for dyeing, adopt a stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com