A functional one-way moisture-absorbing and sweat-wicking super-dry fabric and its production process

A one-way moisture absorption, moisture absorption and perspiration technology, applied in the field of textile fabrics, can solve the problems of poor washing effect, hard fabric feel, unsatisfactory moisture absorption and perspiration effect, etc. water effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

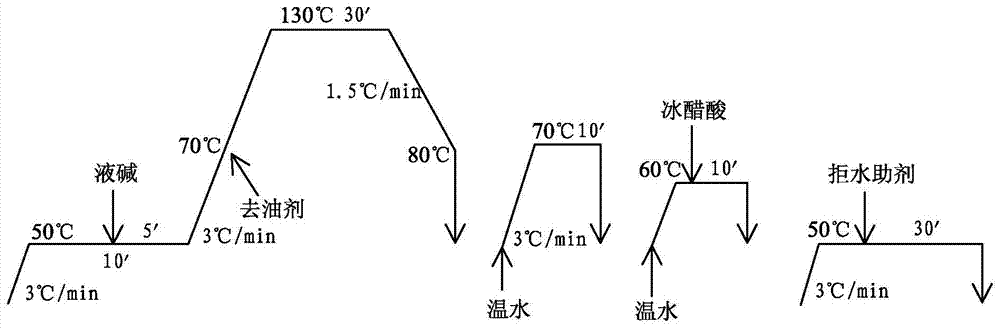

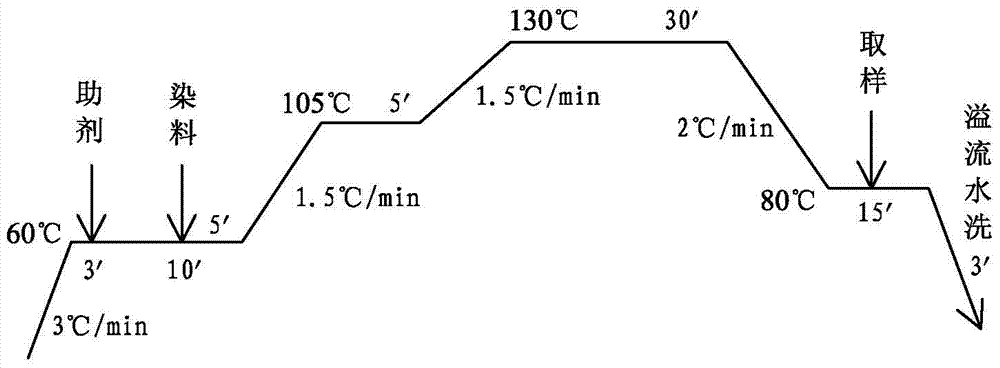

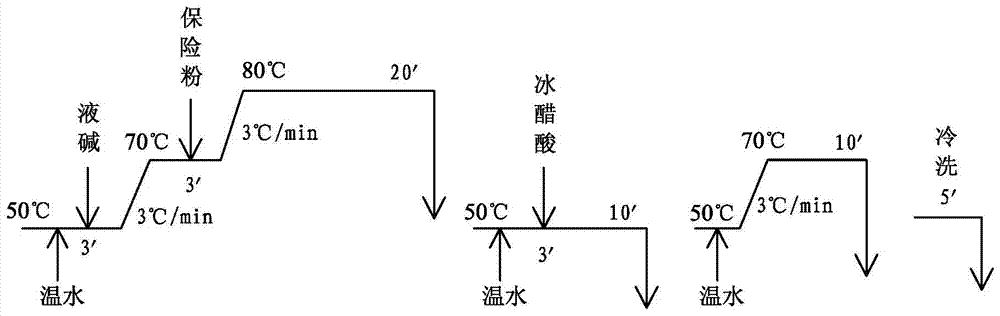

[0036] refer to figure 1 , figure 2 and image 3 , a production process of a functional one-way moisture-absorbing and sweat-wicking ultra-dry fabric, which includes the following steps in sequence:

[0037] ①Green yarn treatment, in the yarn dyeing machine, ordinary polyester filaments are sequentially treated with degreasing, film removal and water repelling processes to completely remove yarn oil stains, change the original surface structure of polyester filaments, and make them produce uneven or honeycomb structures , and then make the water-repellent additive better combine with the polyester yarn, strengthen its adhesion and durability, significantly improve the water-repellent effect, and ensure the uniformity and stability of the one-way moisture transfer effect of the product.

[0038] a. Degreasing and film removal process, put ordinary polyester filaments in water, first gradually heat the water to 50°C at 3°C / min, keep the temperature at 50°C for 10 minutes, add...

Embodiment 2

[0048] refer to figure 1 , figure 2 and image 3 , The difference between this embodiment and Embodiment 1 is that in the weaving process, 54% of the T75D / 72F moisture-wicking polyester filament and 46% of the T75D / 72F treated by the oil-removing, film-removing and water-repellent processes Ordinary polyester filaments are woven into gray fabrics with weft-knitted double-sided structure through double-sided circular knitting machines; odd-numbered paths are threaded into moisture-absorbing and sweat-wicking polyester filaments, and the yarn length is 28cm / 100G; And ordinary polyester filament after water-repellent process, the yarn length is 24cm / 100G.

[0049] The performance parameters of the functional one-way moisture-absorbing and sweat-wicking ultra-dry fabric produced by the above two examples are:

[0050]

[0051] The physical indicators of the products have reached the enterprise standard of Q / FZFZ015-2013 "Functional One-way Moisture Absorption and Perspirati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com