Underwear fabric and processing technique thereof

A technology of underwear fabric and processing technology, which is applied in the direction of fabric surface trimming, heating/cooling fabric, textile material treatment, etc., to achieve the effect of good wrinkle resistance and shape retention, three-dimensional comfort of mold cup forming, and good color fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

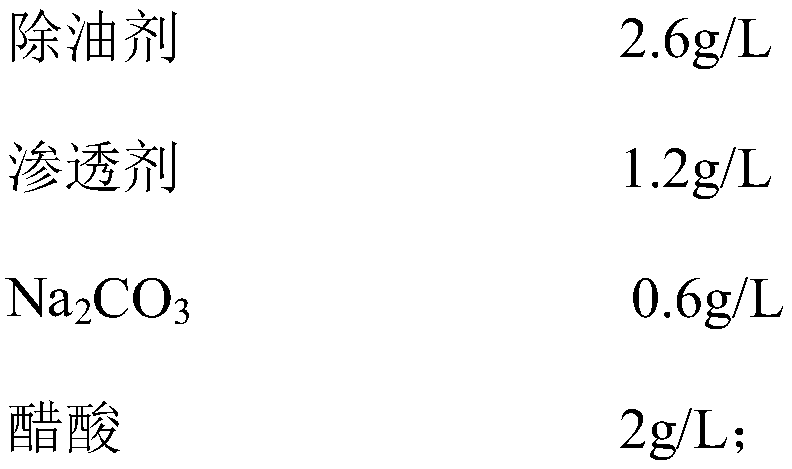

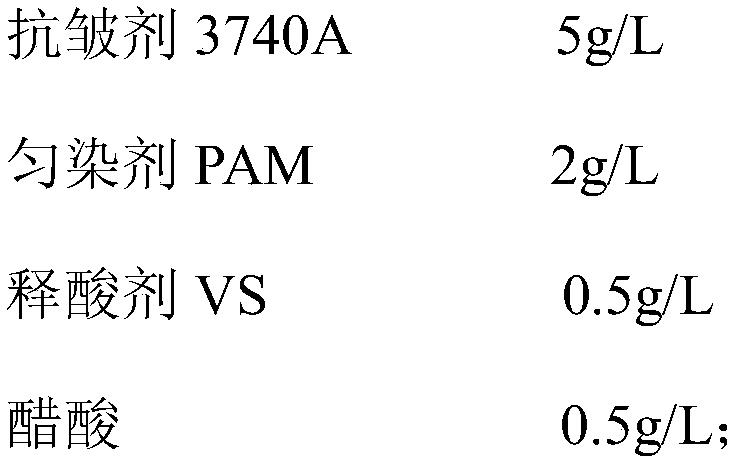

Embodiment 1

[0051] 1) Weaving: Use 30D nylon yarn with a yarn length of 44cm / 100G to knit with needles on the knitting needles of the upper dial, and at the same time knit with needles on the lower needles to form a double-sided weave with needles; the length of the yarn is 26.8cm / 100G 70D nylon yarn and 11.8cm / 100G 30D spandex yarn with a yarn length of 11.8cm / 100G carry out needle knitting on the knitting needles of the upper dial and keep the knitting needles of the lower dial from knitting to form the upper unilateral weave; The 70D nylon yarn with a thread length of 27.5cm / 100G and the 30D spandex yarn with a yarn length of 11.8cm / 100G are knitted on the knitting needles of the lower dial and the knitting needles of the upper dial are not knitted to form a lower unilateral weave; The upper unilateral weave, the needle-containing double-sided weave and the lower unilateral weave are cyclically knitted by a weft knitting method to produce a fabric with an upper unilateral weave, an air ...

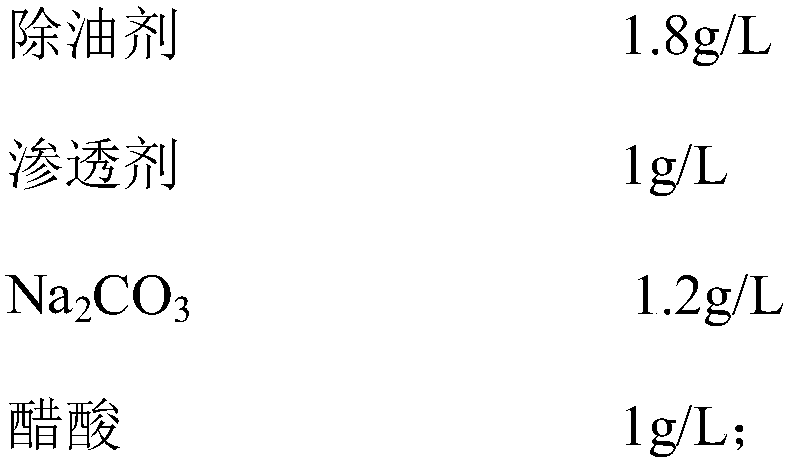

Embodiment 2

[0058] 1) Weaving: Use 30D nylon yarn with a yarn length of 44cm / 100G to knit with needles on the knitting needles of the upper dial, and at the same time knit with needles on the lower needles to form a double-sided weave with needles; the length of the yarn is 26.8cm / 100G 70D nylon yarn and 12cm / 100G 30D spandex yarn with a yarn length of 12cm / 100G are used for knitting on the knitting needles of the upper dial and the knitting needles of the lower dial are not knitted to form the upper unilateral weave; The 70D nylon yarn with a length of 27.4cm / 100G and the 30D spandex yarn with a yarn length of 12cm / 100G are knitted on the knitting needles of the lower dial and the knitting needles of the upper dial are not knitted to form a lower unilateral weave; Unilateral weave, needle-containing double-sided weave and lower unilateral weave are cyclically woven by weft knitting to produce fabrics with upper unilateral weave, air layer, needle-containing double-sided weave, air layer a...

Embodiment 3

[0065]1) Weaving: Use 30D nylon yarn with a yarn length of 44.5cm / 100G to knit with needles on the knitting needles of the upper dial, and at the same time knit with needles on the lower needles to form a double-sided weave with needles; The 70D nylon yarn of 26.5cm / 100G and the 30D spandex yarn with a yarn length of 11.5cm / 100G are knitted on the knitting needles of the upper dial and the knitting needles of the lower dial are not knitted to form the upper unilateral weave; The 70D nylon yarn with a yarn length of 27.1cm / 100G and the 30D spandex yarn with a yarn length of 11.7cm / 100G are knitted on the knitting needles of the lower dial and the knitting needles of the upper dial are not knitted to form a lower unilateral weave ;The upper unilateral weave, needle-containing double-sided weave and lower unilateral weave are cyclically knitted by the weft knitting method to make fabrics with upper unilateral weave, air layer, needle-containing double-sided weave, air layer and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com