Catalytic composite anti-bacterial fiber and preparation method and application thereof

A composite antibacterial and fiber technology, applied in the field of fiber materials, can solve the problems of poor antibacterial function, achieve good moisture absorption and quick drying, reduce use, ensure stability and antibacterial durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

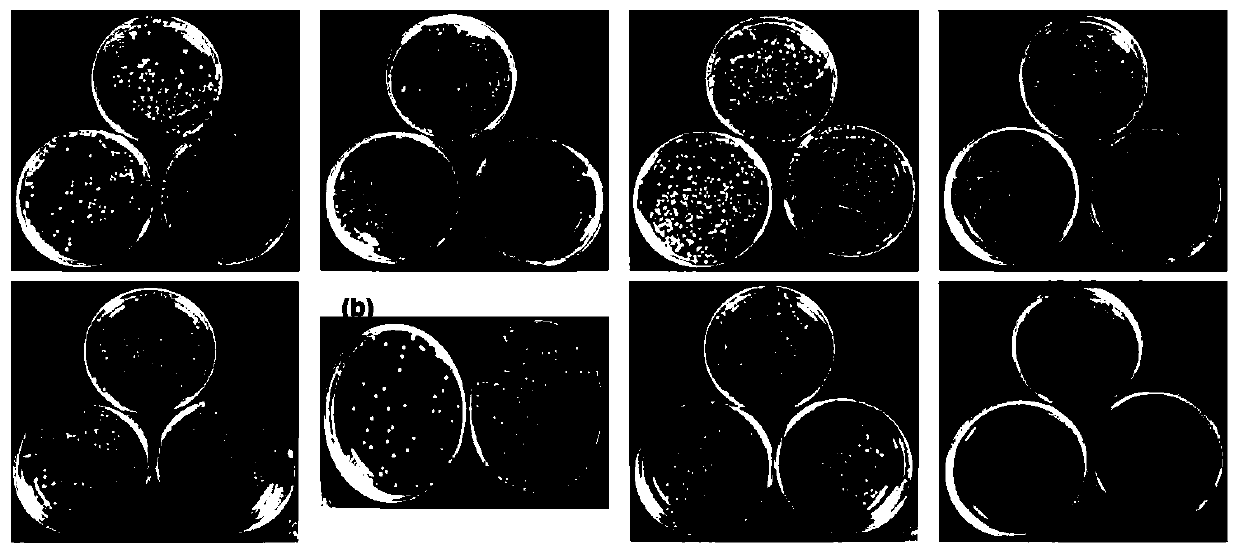

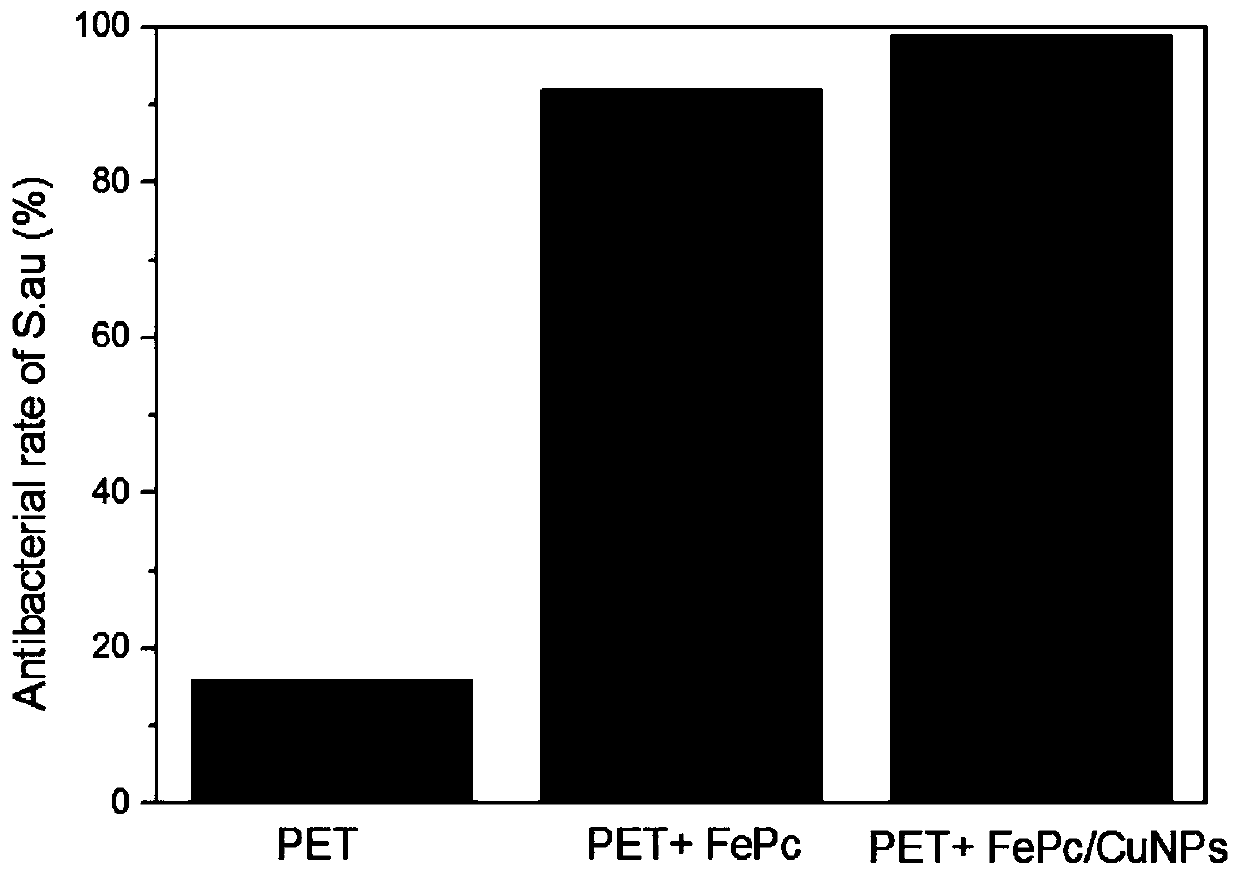

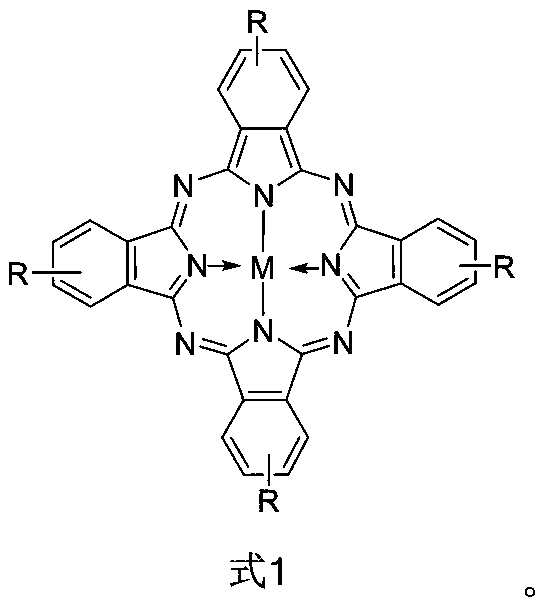

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the catalytic composite antibacterial fiber described in the above technical solution, comprising the following steps:

[0044] Mix the composite antibacterial catalyst, additives and polymers and then granulate to obtain functional masterbatches;

[0045] The functional masterbatch is mixed with the polymer matrix and subjected to profile spinning treatment to obtain the catalyzed composite antibacterial fiber.

[0046] In the invention, the compound antibacterial catalyst, additive and high polymer are mixed and granulated to obtain functional master batches. In the present invention, the mixing is preferably performed at 110-260°C. In the present invention, the mixing method is preferably stirring, the stirring speed is preferably 120±10 r / min, and the stirring time is preferably 2-3 minutes.

[0047] In the present invention, the granulation preferably includes melting the obtained mixture through a screw ...

Embodiment 1

[0056] (1) Nano-copper (maximum particle size 100nm, median particle size 50nm), polyester chip, surfactant (sodium dodecylsulfonate) and silane coupling agent (methyltriethoxysilane) Melt and mix at 260°C, stir at a speed of 120r / min for 2min, then extrude through a screw extruder, cool, draw, pelletize and dry to obtain a functional masterbatch; the total mass of the functional masterbatch is Benchmark meter, the mass percentage of nano-copper is 26%, the mass percentage of additive is 4%, and the mass percentage of polyester is 70%;

[0057] (2) After drying the functional masterbatch and polyester chips, melt and mix them at 220°C, stir them at a speed of 120r / min for 2min, and transport them to the spinning box through a screw extruder for spinning; the screw extruder The temperature inside the heating box assembly is 260°C. Slowly heat up the mixed raw materials. The barrel temperature of the screw extruder is 270°C. Spinning through a special-shaped spinneret at a spinn...

Embodiment 2

[0063] (1) with embodiment 1, difference is that antibacterial catalyst is nano-zinc (maximum particle diameter 100nm, median particle diameter is 50nm);

[0064] (2) with embodiment 1, make nano-zinc antibacterial fiber;

[0065] (3) With embodiment 1, the above-mentioned nano-zinc antibacterial fiber obtained above is coiled and shaped at 900m / min, and cooled by cross blowing at 20°C to obtain final product.

[0066] According to the third part of "GB / T20944.3-2008 Evaluation of Antibacterial Performance of Textiles": the steps of the shock method, the antibacterial activity test was carried out on the nano-zinc antibacterial fiber prepared in this example and the nano-zinc antibacterial fiber after washing 50 times.

[0067] Experimental results show that the antibacterial rate of the nano-zinc antibacterial fiber of this embodiment to Staphylococcus aureus ≥ 95%, the bacteriostatic rate to Escherichia coli ≥ 95%, and the bacteriostatic rate to Candida albicans ≥ 85%.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com