Production equipment of hydrophilic moisture-conducting secondary plied porous fibers and production method of porous fibers

A technology of porous fiber and production equipment, which is applied in the production of complete sets of equipment for artificial threads, fiber treatment, and clustering of newly extruded filaments, etc. problems, to avoid fiber bifurcation and breakage, improve product quality, and achieve uniform tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

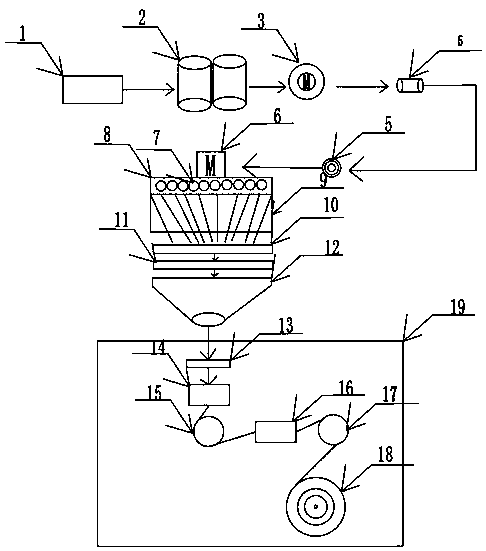

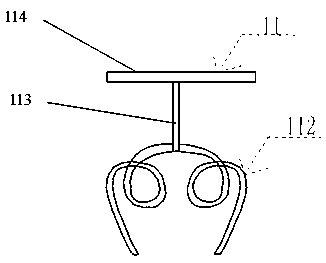

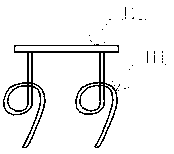

[0098] Specifically, such as Figure 1 to Figure 3 As shown, a method for preparing a hydrophilic and moisture-conducting secondary ply porous fiber 300D / 546 is produced by using the above-mentioned production equipment, which specifically includes the following steps:

[0099] Polyester device→filter→booster pump→heat exchanger→overpass plate static mixer→metering pump melt extrusion→spinning assembly spinneret melt extrusion 20 bundles of filaments→circular blowing cooling forming→double oil nozzle Oil→single-rod, double-headed, double-headed yarn guide, wire guide hook frame guidance→spinning tunnel→comb-shaped yarn splitter to form 10 bundles of yarn at one time→pre-netter→first godet→secondary at the main networker Plying is 5 bundles of tow → the second godet → winding forming.

[0100] Among them, in the polyester reaction, from the level of polyester molecular structure design, polyhydroxy monomers and polyethylene glycol macromolecules are introduced into the polyester...

Embodiment 2

[0104] Such as Figure 1 to Figure 3 As shown, a method for preparing a hydrophilic and moisture-conducting secondary plied porous fiber 350D / 546f is produced by using the above-mentioned production equipment, which specifically includes the following steps:

[0105] Polyester device→filter→booster pump→heat exchanger→overpass plate static mixer→metering pump melt extrusion→spinning assembly spinneret melt extrusion 20 bundles of filaments→circular blowing cooling forming→double oil nozzle Oil→single-rod, double-headed, double-headed yarn guide, wire guide hook frame guidance→spinning tunnel→comb-shaped yarn splitter to form 10 bundles of yarn at one time→pre-netter→first godet→secondary at the main networker Plying is 5 bundles of tow → the second godet → winding forming.

[0106] Among them, in the polyester reaction, from the level of polyester molecular structure design, polyhydroxy monomers and polyethylene glycol macromolecules are introduced into the polyester molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com