High-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material

A flame retardant and antistatic polypropylene material technology, which is applied in the field of high temperature and high humidity resistant halogen-free flame retardant and antistatic polypropylene materials, can solve the problem that glass fiber reinforced polypropylene materials cannot achieve high glow wire, cannot effectively prevent static electricity, and cannot Normal use and other problems, to achieve the effect of retaining mechanical and mechanical properties, excellent antistatic performance, and low requirements for preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

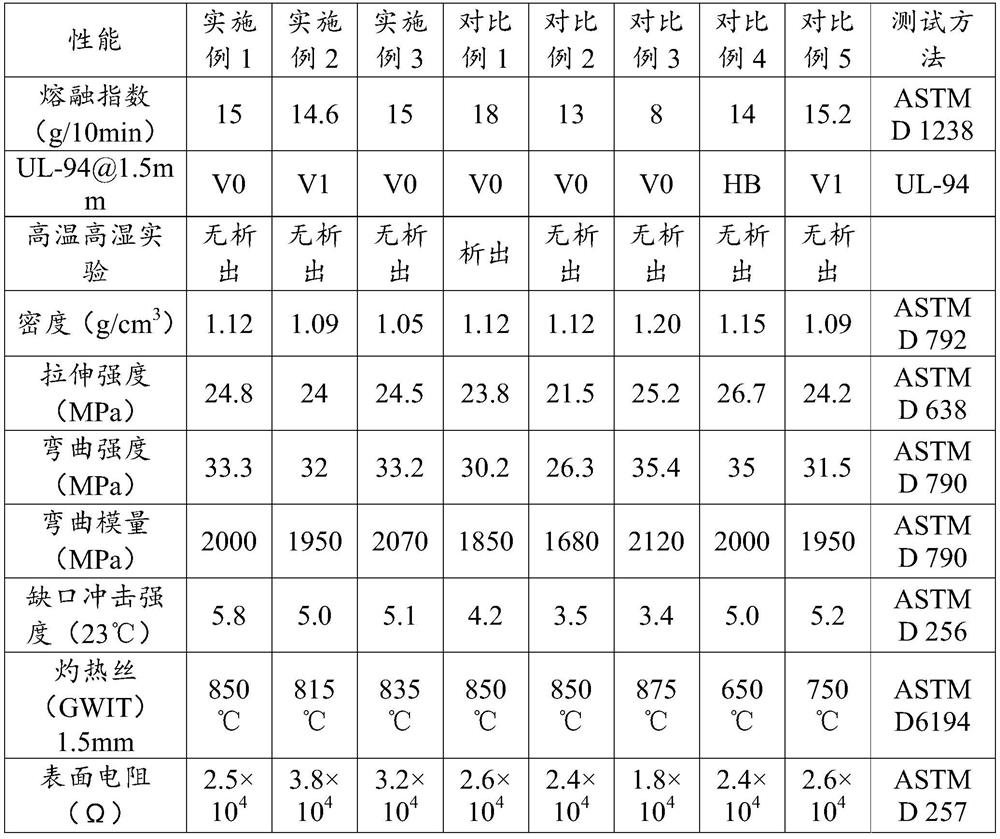

Examples

Embodiment 1

[0026] An embodiment of the high-temperature, high-humidity, halogen-free, flame-retardant and antistatic polypropylene material of the present invention.

[0027] The high-temperature, high-humidity, halogen-free, flame-retardant and antistatic polypropylene material described in this embodiment includes the following components by weight: 60 parts of polypropylene resin, 20 parts of expandable graphite, 0.2 parts of coupling agent, and halogen-free flame retardant 15 parts, 2 parts of compatibilizer, 0.4 part of lubricant, 3 parts of toughening agent and 0.2 part of antioxidant; The polypropylene resin is polypropylene resin PPK7726; The mesh number of described expandable graphite is 100 mesh, can The expansion multiple is 300; the compatibilizer is PP-g-MAH; the halogen-free flame retardant is diethylphosphinate; the lubricant is silicone powder; the coupling agent is isopropyl Base tri(isostearyl) titanate; the antioxidant includes 0.1 part of hindered amine antioxidant 1...

Embodiment 2

[0033]The high-temperature, high-humidity, halogen-free, flame-retardant and antistatic polypropylene material described in this embodiment includes the following components in parts by weight: 40 parts of polypropylene resin, 5 parts of expandable graphite, 0.5 parts of coupling agent, and halogen-free flame retardant 8 parts, 0.5 part of compatibilizer, 0.2 part of lubricant, 2 parts of toughening agent and 0.2 part of antioxidant; Described polypropylene resin is polypropylene resin PPK7726; The mesh number of described expandable graphite is 100 mesh, can The expansion factor is 200; the compatibilizer is POE-g-MAH; the halogen-free flame retardant is anhydrous zinc borate; the lubricant is silicone powder; the coupling agent is isopropyl tri( Isostearyl) titanate; the antioxidant includes 0.1 part of hindered amine antioxidant 1010 parts and 0.1 part of phosphite antioxidant 168; the toughening agent is SEBS elastomer.

[0034] The preparation method of the high-temperatu...

Embodiment 3

[0036] The high-temperature, high-humidity, halogen-free, flame-retardant and antistatic polypropylene material described in this embodiment includes the following components in parts by weight: 50 parts of polypropylene resin, 15 parts of expandable graphite, 1 part of coupling agent, and a halogen-free flame retardant 12 parts, 2 parts of compatibilizer, 0.3 part of lubricant, 5 parts of toughening agent and 0.3 part of antioxidant; Described polypropylene resin is polypropylene resin PPK7726; The mesh number of described expandable graphite is 100 mesh, can The expansion ratio is 250; the compatibilizer is EVA-g-MAH; the halogen-free flame retardant is diethylphosphinate; the lubricant is silicone powder; the coupling agent is isopropyl Base tri(isostearyl) titanate; said antioxidant includes 0.1 part of hindered amine antioxidant 1010 parts and 0.2 part of phosphite antioxidant 168; said toughening agent is EAA elastomer.

[0037] The preparation method of the high-tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com