Halogen-free flame-retardant low-dielectric-loss glass fiber reinforced polypropylene material

A polypropylene material and low dielectric technology, applied in the field of halogen-free flame retardant and low dielectric loss glass fiber reinforced polypropylene material, can solve the problems of non-environmental protection, high harmfulness, failure to achieve high glow wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

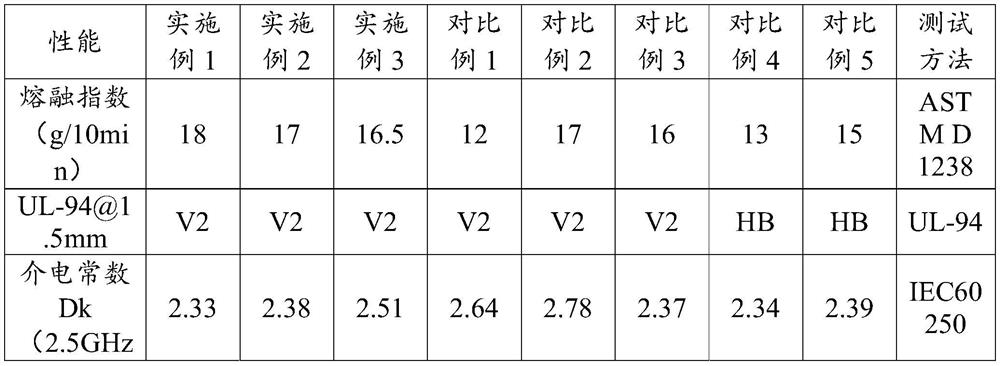

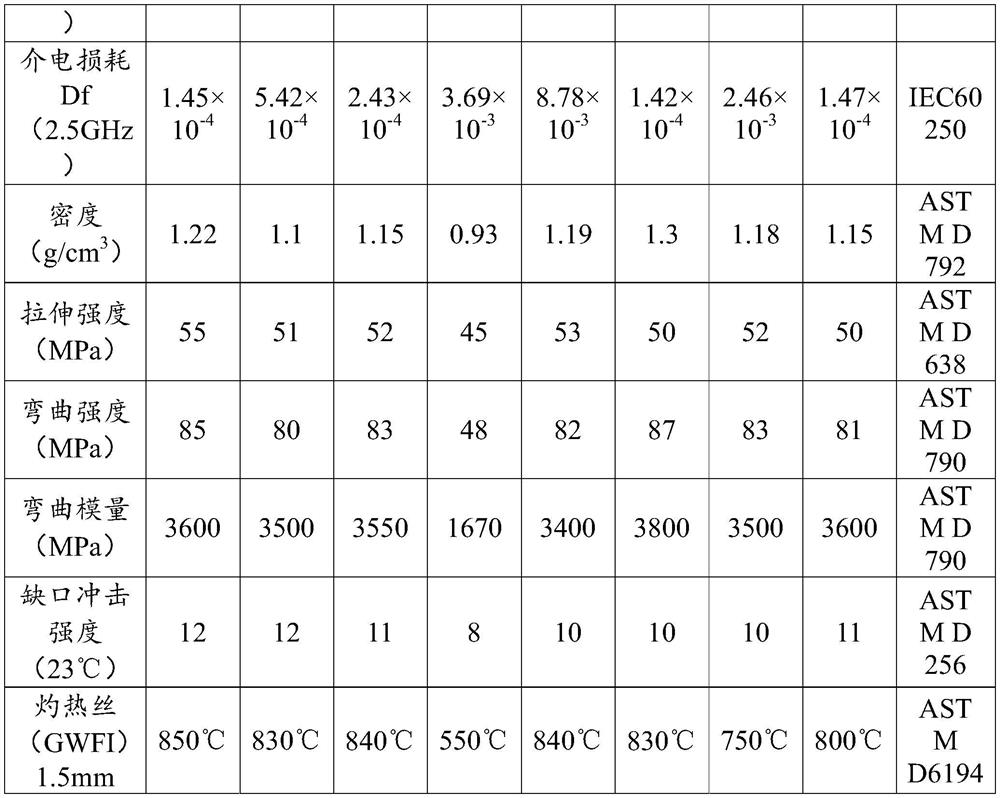

Examples

Embodiment 1

[0025] An embodiment of the halogen-free flame retardant low dielectric loss glass fiber reinforced polypropylene material of the present invention.

[0026] The halogen-free flame-retardant low dielectric loss glass fiber reinforced polypropylene material described in this embodiment includes the following components in parts by weight: 70 parts of polypropylene resin, 40 parts of low dielectric loss glass fiber, and 3 parts of halogen-free flame retardant , 2 parts of compatibilizer, 0.2 part of lubricant, 0.3 part of weather resistance additive and 0.4 part of antioxidant; said polypropylene resin comprises 50 parts of polypropylene resin PPZ30S and 20 parts of polypropylene resin PPK8009; said low dielectric loss The dielectric loss of glass fiber at 4-4.5GHz frequency is 4.5×10 -2 , the fiber diameter of the low dielectric loss glass fiber is 14 μm; the compatibilizer is PP-g-MAH; the halogen-free flame retardant is diethylphosphinate; the lubricant is silicone powder; t...

Embodiment 2

[0034] The halogen-free flame-retardant low dielectric loss glass fiber reinforced polypropylene material described in this embodiment includes the following components in parts by weight: 40 parts of polypropylene resin, 15 parts of low dielectric loss glass fiber, and 2 parts of halogen-free flame retardant , 1 part of compatibilizer, 0.2 part of lubricant, 0.3 part of weather resistance additive and 0.3 part of antioxidant; the polypropylene resin includes 40 parts of polypropylene resin PPZ30S; the low dielectric loss glass fiber is The dielectric loss at frequency is 4.5×10 -2 , the fiber diameter of the low dielectric loss glass fiber is 14 μm; the compatibilizer is POE-g-MAH; the halogen-free flame retardant is melamine; the lubricant is silicone powder; The antioxidant is UV2908; the antioxidant includes 0.1 part of hindered amine antioxidant 1010 parts and 0.2 part of phosphite antioxidant 168.

[0035] The preparation method of the halogen-free flame-retardant low d...

Embodiment 3

[0037]An embodiment of the halogen-free flame retardant low dielectric loss glass fiber reinforced polypropylene material of the present invention.

[0038] The halogen-free flame-retardant low dielectric loss glass fiber reinforced polypropylene material described in this embodiment includes the following components in parts by weight: 50 parts of polypropylene resin, 25 parts of low dielectric loss glass fiber, and 4 parts of halogen-free flame retardant , 4 parts of compatibilizer, 0.5 part of lubricant, 0.5 part of weather resistance additive and 0.2 part of antioxidant; said polypropylene resin comprises 30 parts of polypropylene resin PPZ30S and 20 parts of polypropylene resin PPK8009; said low dielectric loss The dielectric loss of glass fiber at 4-4.5GHz frequency is 4.5×10 -2 , the fiber diameter of the low dielectric loss glass fiber is 14 μm; the compatibilizer is EEA; the halogen-free flame retardant is diethylphosphinate; the lubricant is EBS graft; The weather r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com