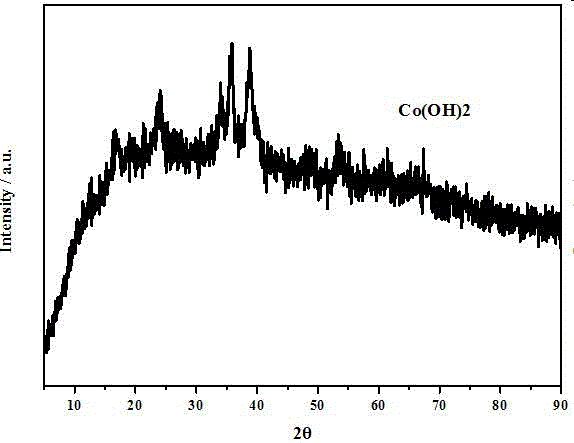

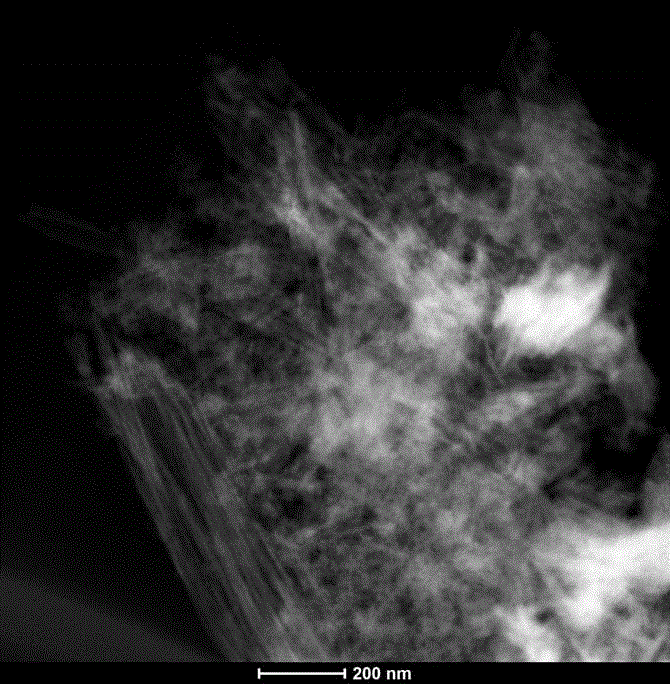

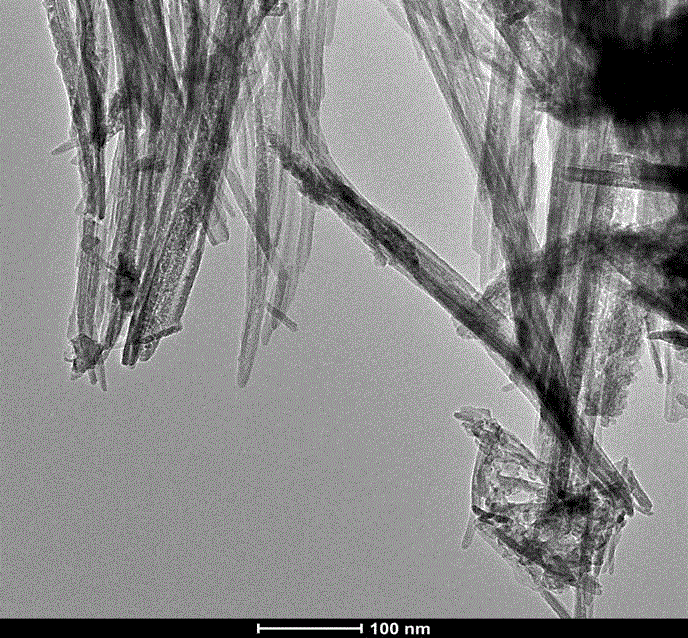

Co(OH)<2> with nano-tube structures, method for preparing Co(OH)<2> and application thereof

A technology for nanotubes and uses, applied in the field of nanotube-structured Co2 and its preparation, can solve the problems of high price and scarce availability, and achieve the effects of low cost, increased catalytic active sites, and low requirements for preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Configure CuSO separately 4 (Concentration is 1mol / L), C 6 h 12 o 6 (concentration is 2mol / L) and NaOH (concentration is 2.5mol / L) solution 25 mL each; the CuSO 4 The solution was added into a 150 mL three-neck reaction flask, stirred at room temperature, and NaOH solution was slowly added, and the stirring was continued for 10 min after the addition, to obtain Cu(OH) 2 slurry, warm to 50°C, and bring the heat to 50°C 6 h 12 o 6 The solution was added to the reaction flask and reacted at constant temperature for 1 h to prepare Cu 2 The O slurry was suction filtered, washed three times with water, then washed three times with absolute ethanol, and dried at 60 °C for 24 h to obtain Cu 2 O;

[0026] (2) Weigh the Cu obtained in step (1) 2 Put 100 mg of O, 34 mg of cobalt chloride hexahydrate, and 3.333 g of SDS into a beaker, add 50 mL of distilled water and 50 mL of absolute ethanol, sonicate for 5 min, stir for 10 min, and then add 40 mL of 1.0 mol / L Na 2 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com