Method for in-situ preparation of small-size metal oxide on graphene

An in-situ preparation and graphene technology, applied to chemical instruments and methods, lead oxide, carbon compounds, etc., can solve the problems of easy residual impurities, cumbersome process, complicated steps, etc., and achieve high efficiency and purity of the final product, simple operation, avoid The effect of uneven large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

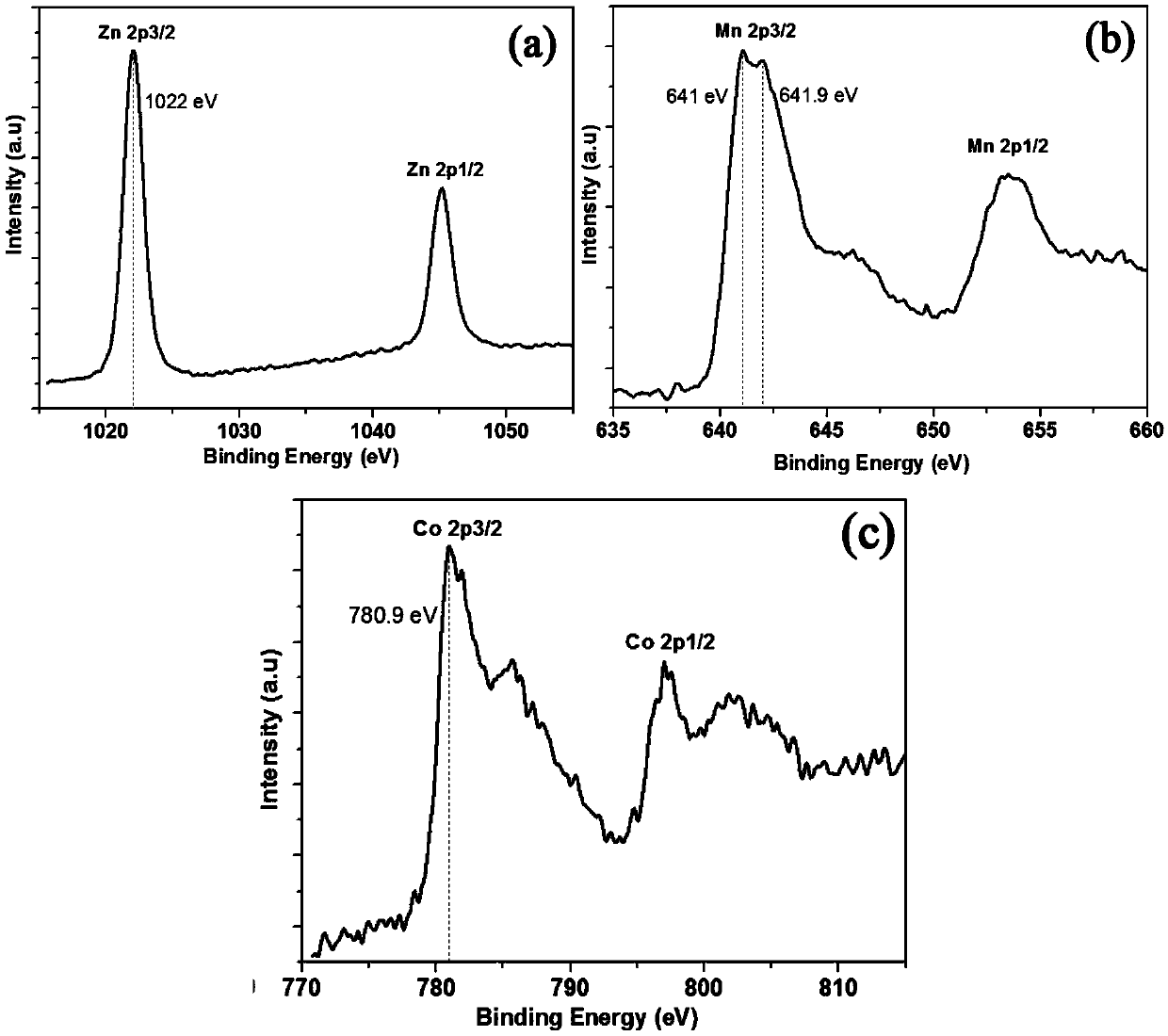

[0022] Specifically, the preparation method of the graphene-metal ion reaction solution may include: mixing graphene, graphene oxide or reduced graphene oxide with a metal ion solution (the metal ion solution may be an acetate solution), and the graphite Graphene-metal ion reaction liquid is obtained after adsorption and complexation of metal ions by ene, graphene oxide or reduced graphene oxide. The metal ion can be Cu 2+ , Zn 2+ 、Co 2+ 、Ni 2+ , Mn 2+ , Pb 2+ at least one of the The graphene oxide or graphene can be the graphene oxide or graphene prepared by the Hummers method in the prior art.

[0023] Further, as Figure 4 As shown, the principle of the method for preparing small-sized metal oxides in situ on graphene provided by the present invention is as follows: because graphene, graphene oxide (i.e. GO) and reduced graphene oxide (i.e. RGO) all have abundant functional groups , large specific surface area, strong ability to transport electrons, and has a stable...

Embodiment 1

[0031] A method for preparing small-sized metal oxides in situ on graphene, comprising the following steps:

[0032] Step A1, mixing reduced graphene oxide (ie RGO) with a zinc acetate solution to obtain a flocculent mixed solution after the reduced graphene oxide has adsorbed and complexed zinc ions.

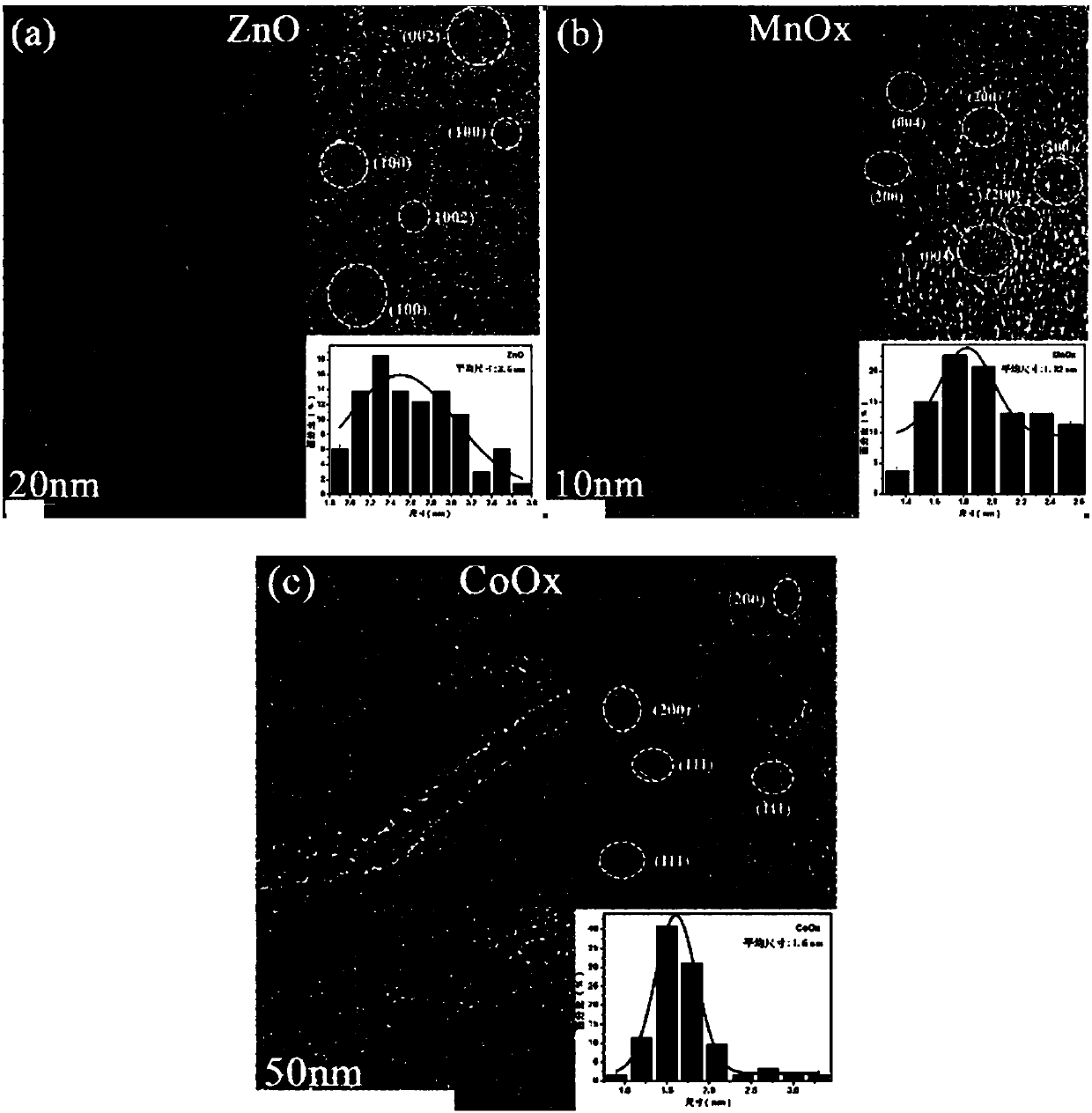

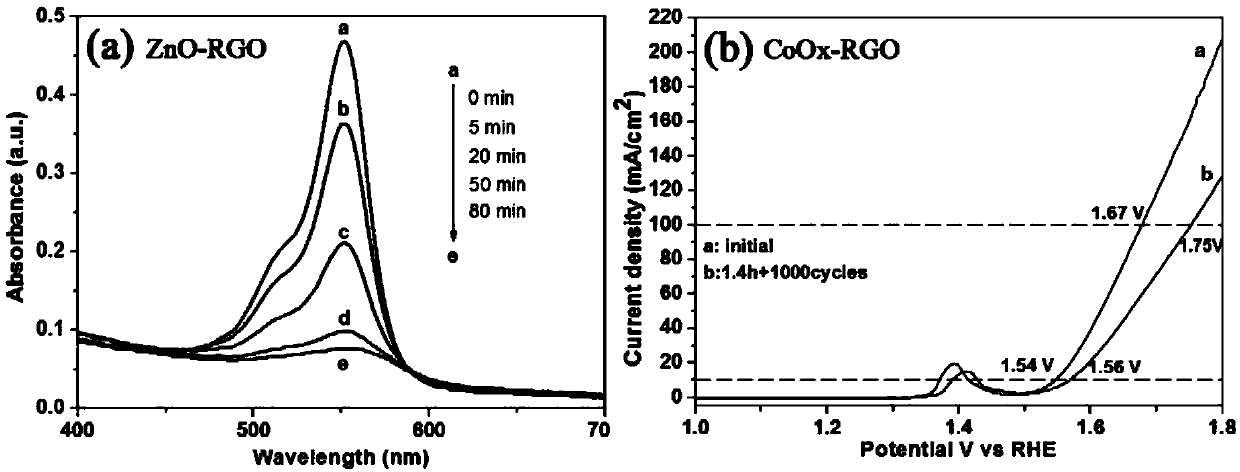

[0033] Step B1, using a laser with a wavelength of 200-600nm to irradiate the flocculent mixed solution after the reduced graphene oxide is adsorbed and complexed with zinc ions, and the irradiation time is 15 minutes, so as to obtain zinc oxide supported by reduced graphene oxide Nanocomposites (ie ZnO-RGO nanocomposites).

Embodiment 2

[0035] A method for preparing small-sized metal oxides in situ on graphene, comprising the following steps:

[0036] Step A2, mixing the reduced graphene oxide (ie RGO) with the manganese acetate solution to obtain a flocculent mixed solution after the reduced graphene oxide has adsorbed and complexed manganese ions.

[0037] Step B2, using a laser with a wavelength of 200-600nm to irradiate the flocculent mixed solution after the reduced graphene oxide is adsorbed and complexed with manganese ions, and the irradiation time is 30 minutes, so as to obtain manganese oxide supported by reduced graphene oxide nanocomposites (i.e. MnO x -RGO nanocomposites).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com