Lubricating type anti-rust oil special for bearing bush

A technology of anti-rust oil and lubricating base oil, which is applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problems that cannot meet the requirements of bearing bush lubrication and anti-rust, achieve good anti-rust effect, reduce friction and wear, The effect of good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

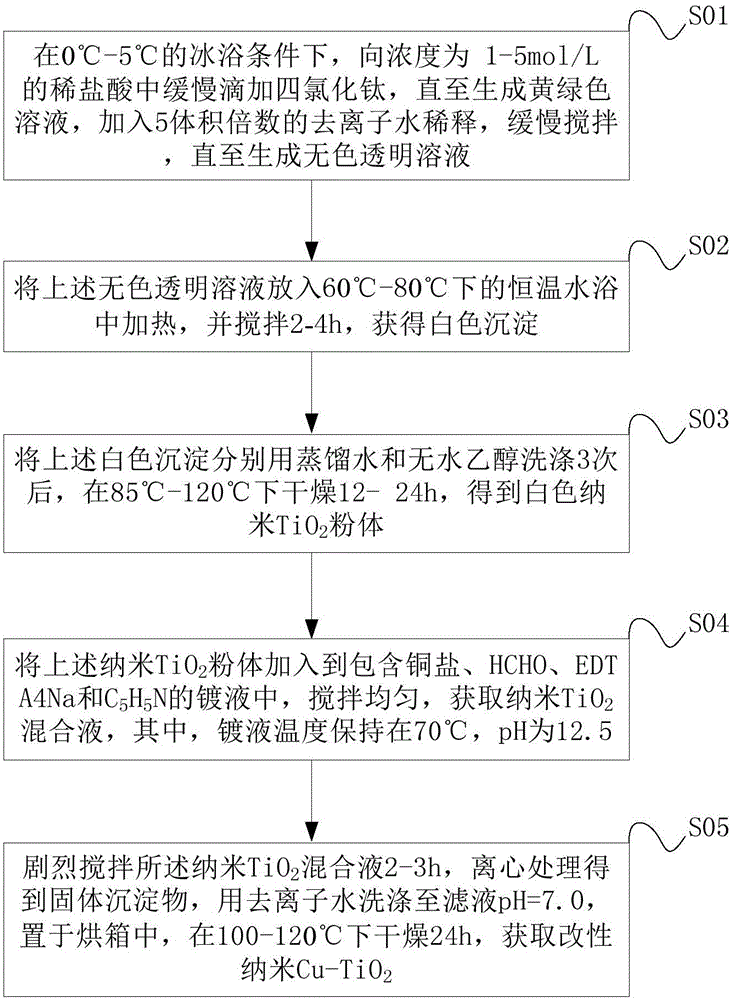

[0029] The modified nano-Cu-TiO provided in this example 2 The preparation methods include:

[0030] Under the condition of ice bath at 0°C-5°C, slowly add titanium tetrachloride dropwise to dilute hydrochloric acid with a concentration of 3mol / L until a yellow-green solution is formed, add 5 volume multiples of deionized water to dilute, and stir slowly until A colorless and transparent solution is generated;

[0031] The above colorless and transparent solution was heated in a constant temperature water bath at 75°C and stirred for 3 hours to obtain a white precipitate;

[0032] The above white precipitate was washed three times with distilled water and absolute ethanol, and dried at 90 °C for 24 h to obtain white nano-TiO 2 Powder;

[0033] Nano TiO 2 The powder is added to the solution containing copper chloride, HCHO, EDTA-4Na and C 5 h 5 In the plating solution of N, stir evenly to obtain nano-TiO 2 Mixed solution, wherein the temperature of the plating solution i...

Embodiment 2

[0042] The modified nano-Cu-TiO provided in this example 2 The preparation methods include:

[0043] Under the condition of ice bath at 0°C-5°C, slowly add titanium tetrachloride dropwise to dilute hydrochloric acid with a concentration of 1mol / L until a yellow-green solution is formed, add 5 volume multiples of deionized water to dilute, and stir slowly until A colorless and transparent solution is generated;

[0044] The above colorless and transparent solution was heated in a constant temperature water bath at 60°C and stirred for 2 hours to obtain a white precipitate;

[0045] The above white precipitate was washed three times with distilled water and absolute ethanol, and dried at 85 °C for 12 h to obtain white nano-TiO 2 Powder;

[0046] Nano TiO 2 The powder was added to the solution containing copper acetate, HCHO, EDTA-4Na and C 5 h 5 In the plating solution of N, stir evenly to obtain nano-TiO 2 Mixed solution, wherein the temperature of the plating solution i...

Embodiment 3

[0049] The modified nano-Cu-TiO provided in this example 2 The preparation methods include:

[0050] Under the condition of ice bath at 0°C-5°C, slowly add titanium tetrachloride dropwise to dilute hydrochloric acid with a concentration of 5mol / L until a yellow-green solution is formed, add 5 volume multiples of deionized water to dilute, and stir slowly until A colorless and transparent solution is generated;

[0051] The above colorless and transparent solution was heated in a constant temperature water bath at 80°C and stirred for 4 hours to obtain a white precipitate;

[0052] The above white precipitate was washed three times with distilled water and absolute ethanol, and dried at 120 °C for 14 h to obtain white nano-TiO 2 Powder;

[0053] Nano TiO 2 The powder was added to the solution containing copper nitrate, HCHO, EDTA-4Na and C 5 h 5 In the plating solution of N, stir evenly to obtain nano-TiO 2 Mixed solution, wherein the temperature of the plating solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com