Compression spring with pre-pressed end and winding and detecting method of compression spring

A technology of compressing springs and winding methods, which is applied in the direction of springs, springs made from wires, springs/shock absorbers, etc., can solve the problems of collision between the end and the adjacent ring, spring breakage, etc., to improve the quality and use requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

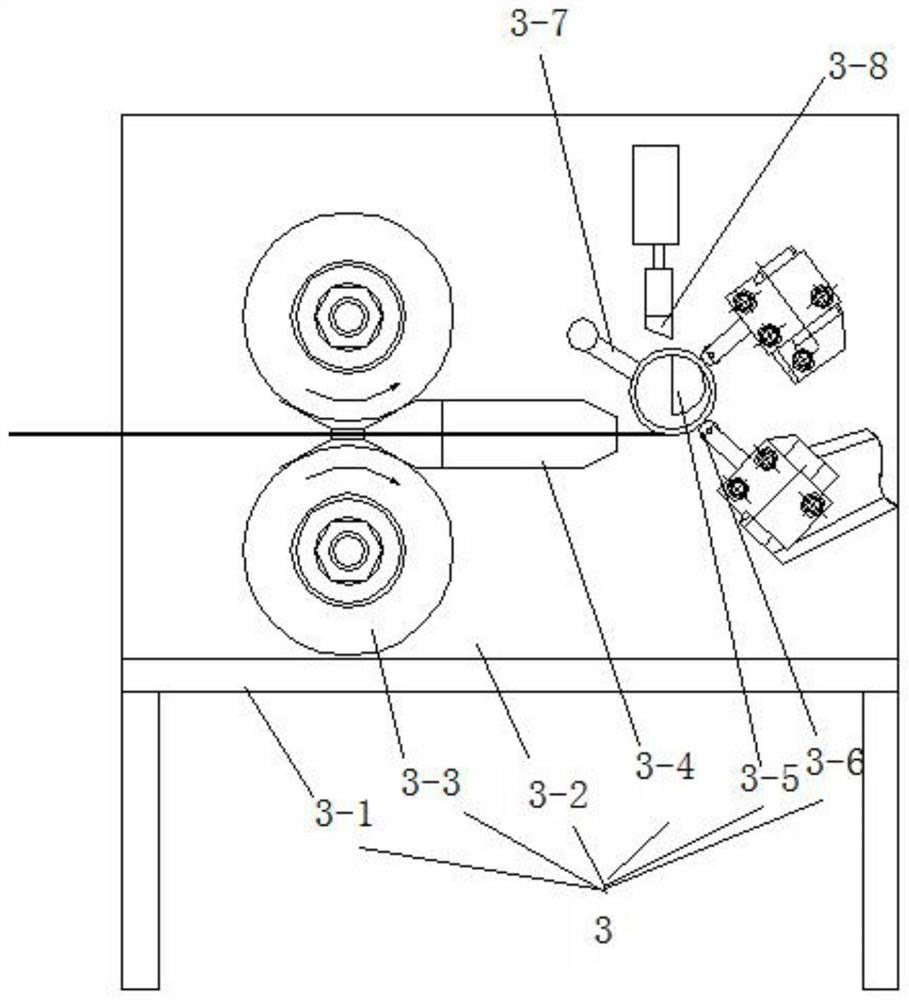

[0048] See attached picture.

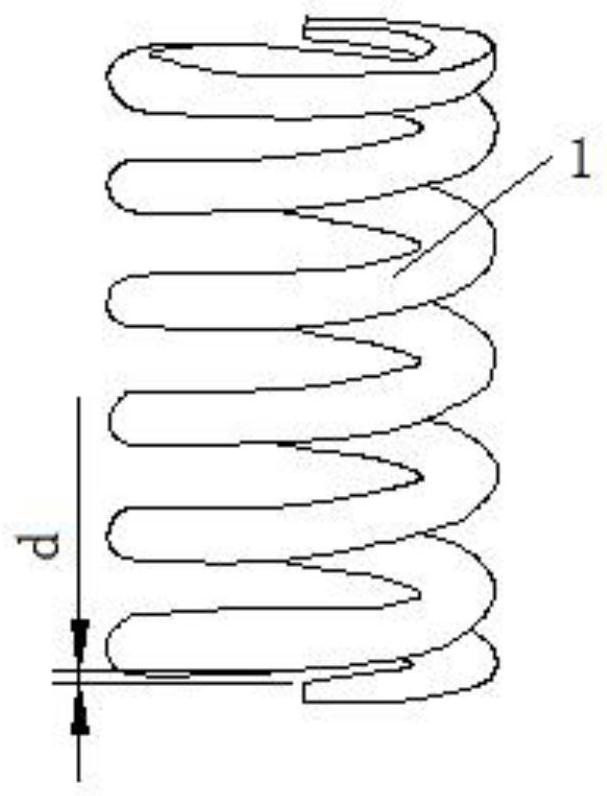

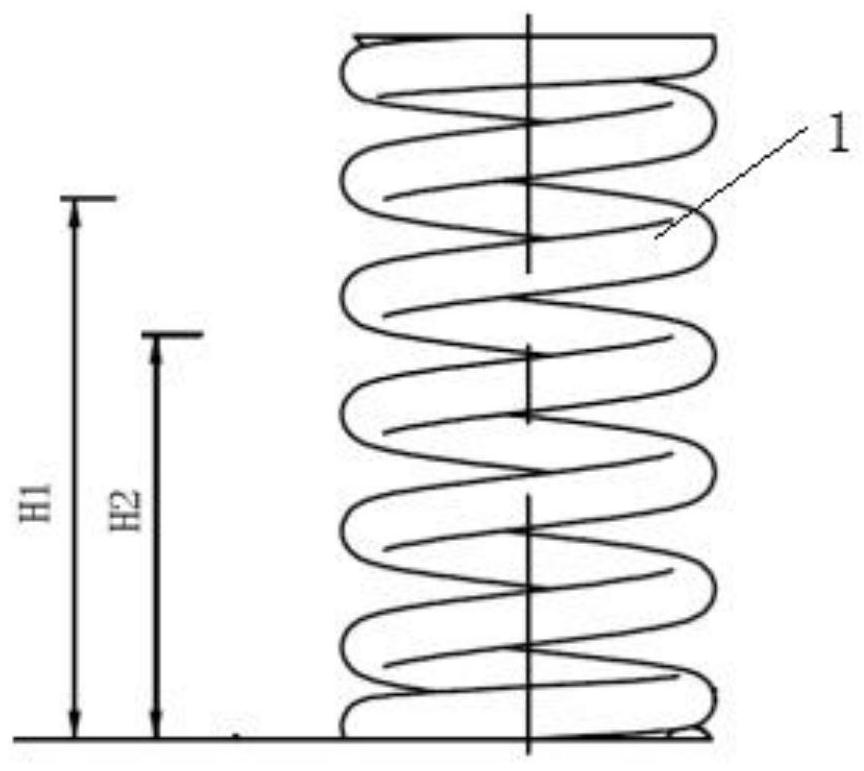

[0049] A compression spring that guarantees a close gap between the end and the adjacent coil, including a spring body 1 produced and processed by pre-compression, there is a gap d between the two ends of the spring body 1 and the corresponding adjacent coil, and the spring body 1 is pressed When the force is compressed, the size of the contact area between the end head and the adjacent ring is the pressing angle θ; the pressing angle θ is the indentation curve formed by the contact between the spring end and the adjacent ring and the arc center position when measured by the induction paper. angle.

[0050] Further, the gap d≤0.1mm. When the compression angle θ is compressed to different positions by force, the angle between the end and the contact area of the adjacent ring is different. When the spring body is compressed to the installation position H1, the corresponding compression angle θ1>36°, when the spring When the body is compressed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com