Natural gas desulfurization system and method

A desulfurization system and natural gas technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problem that natural gas purification technology cannot meet the requirements of natural gas desulfurization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

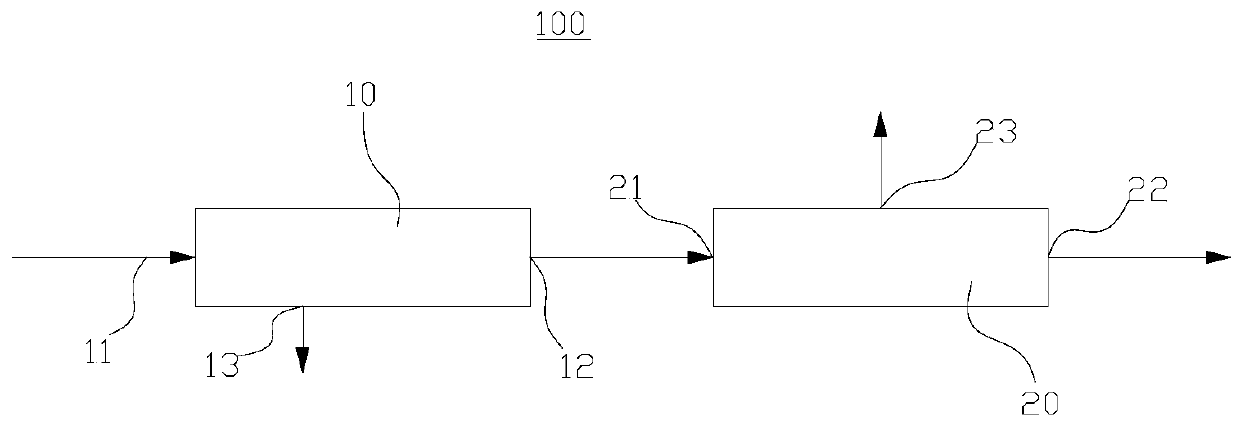

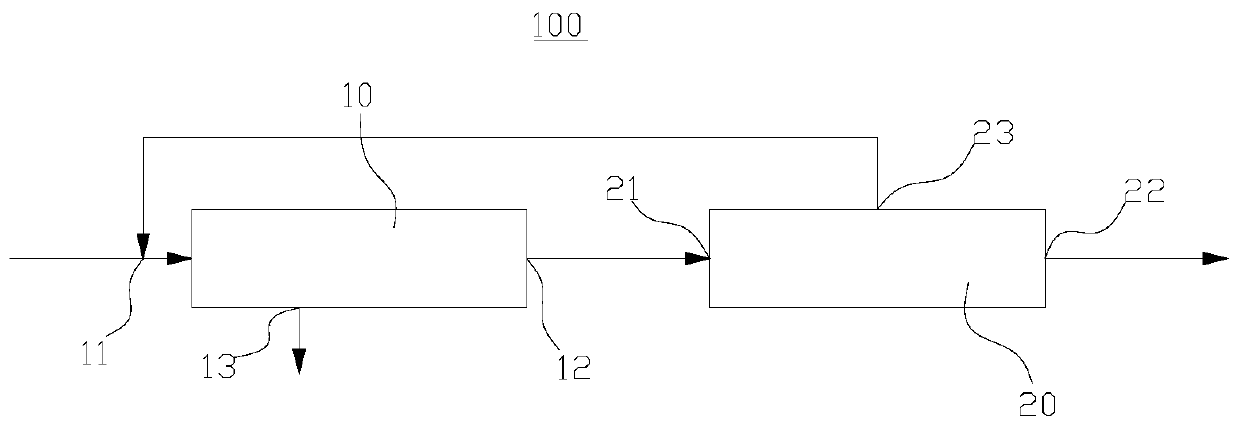

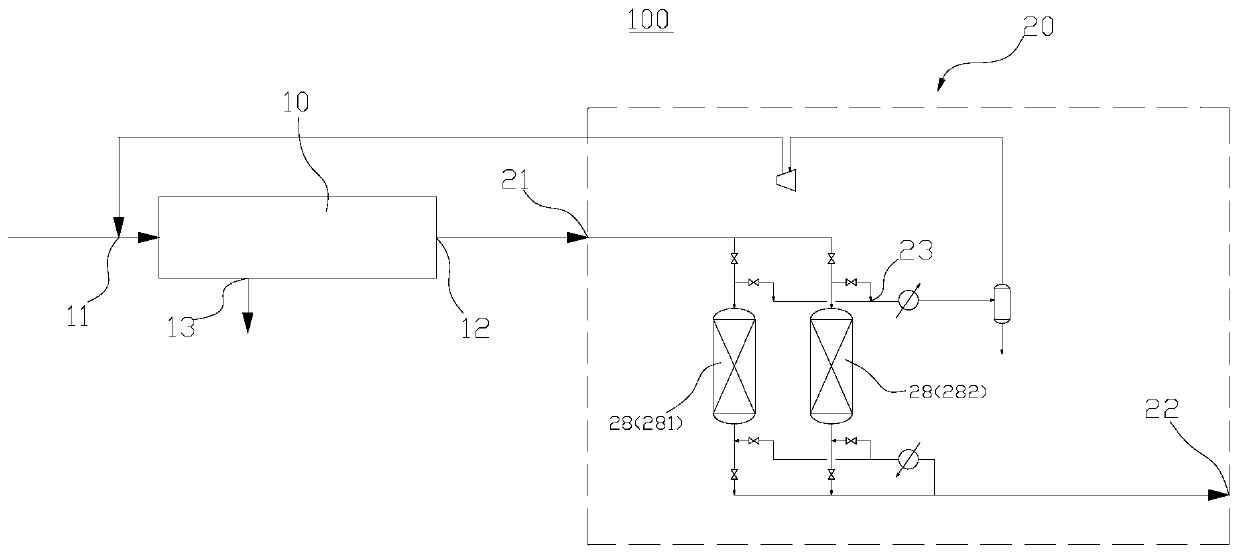

[0071] Such as figure 1 As shown, the embodiment of the present application provides a natural gas desulfurization system 100 , including an MDEA deacidification unit 10 and a TSA desulfurization unit 20 . The deacidification unit has an input port 11 and an output port 12, and the MDEA deacidification unit 10 is configured to perform rough desulfurization treatment on raw natural gas entering through the input port 11 to obtain crude desulfurized natural gas. The TSA desulfurization unit 20 has a first inlet 21 , a first outlet 22 and a second outlet 23 , the output port 12 communicates with the first inlet 21 , and crude desulfurized natural gas can enter the first inlet 21 from the output port 12 . The desulfurization unit is configured to perform fine desulfurization on the crude desulfurized natural gas to obtain finely desulfurized natural gas and first regenerated gas, discharge the finely desulfurized natural gas from the first outlet 22 , and discharge the first regen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com