Energy-saving multifunctional clamping pipe control valve

A multi-functional and energy-saving technology, applied in valve details, diaphragm valves, valve devices, etc., can solve the problems of large lifting force, blockage or stuck, affecting the normal operation of the equipment, etc. of the direct lift solenoid valve, and reduce manual cleaning. frequency, impact prevention, power reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

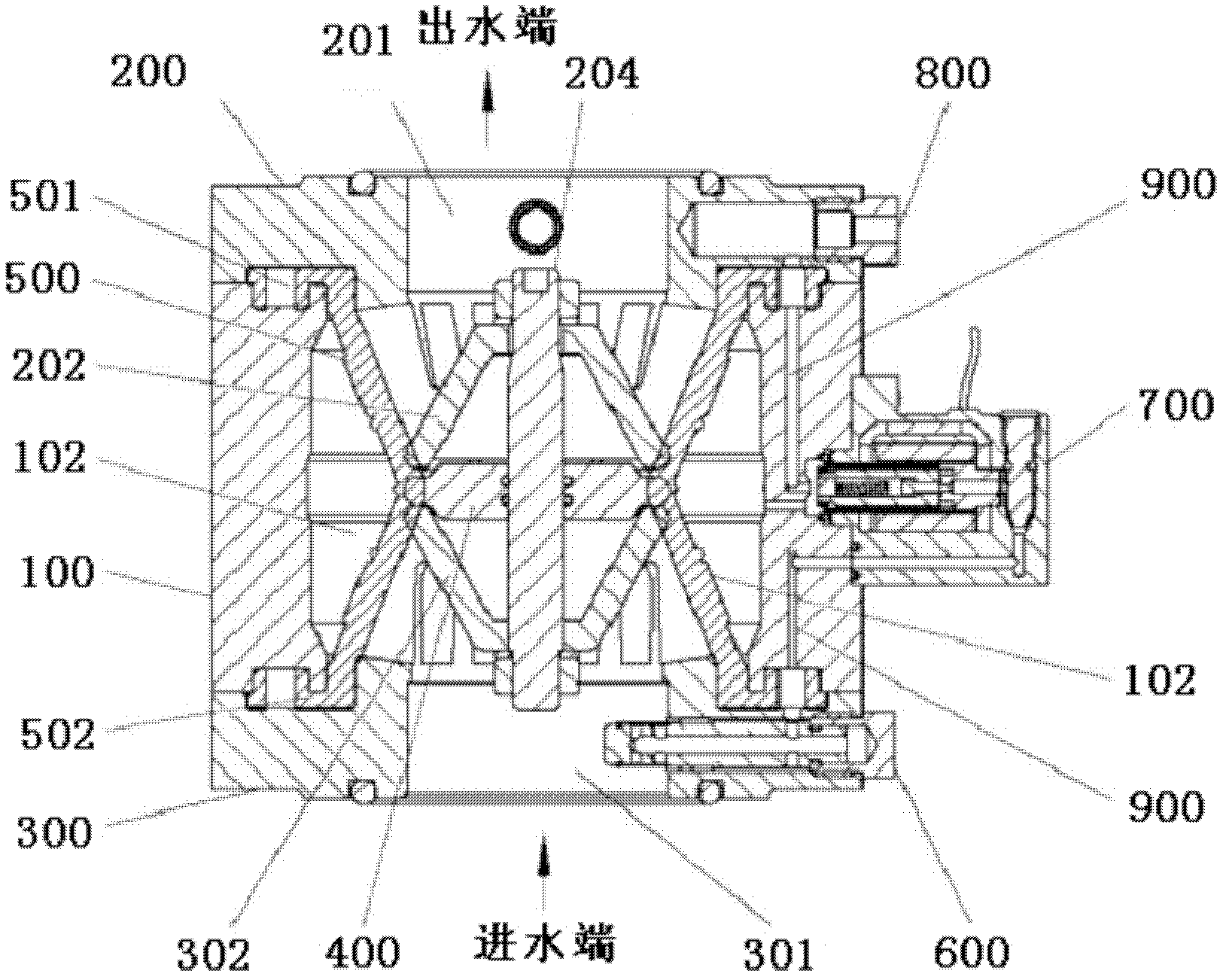

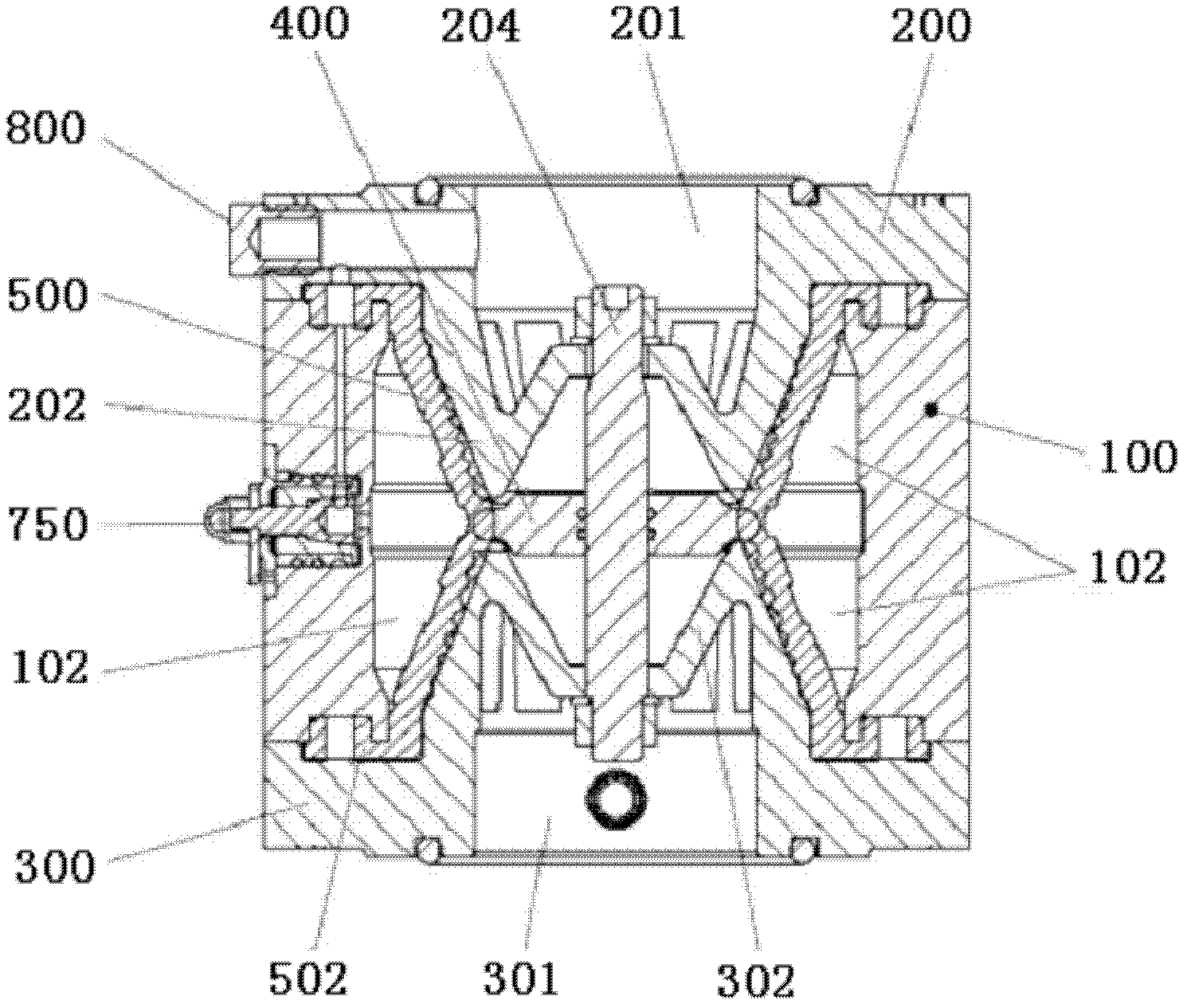

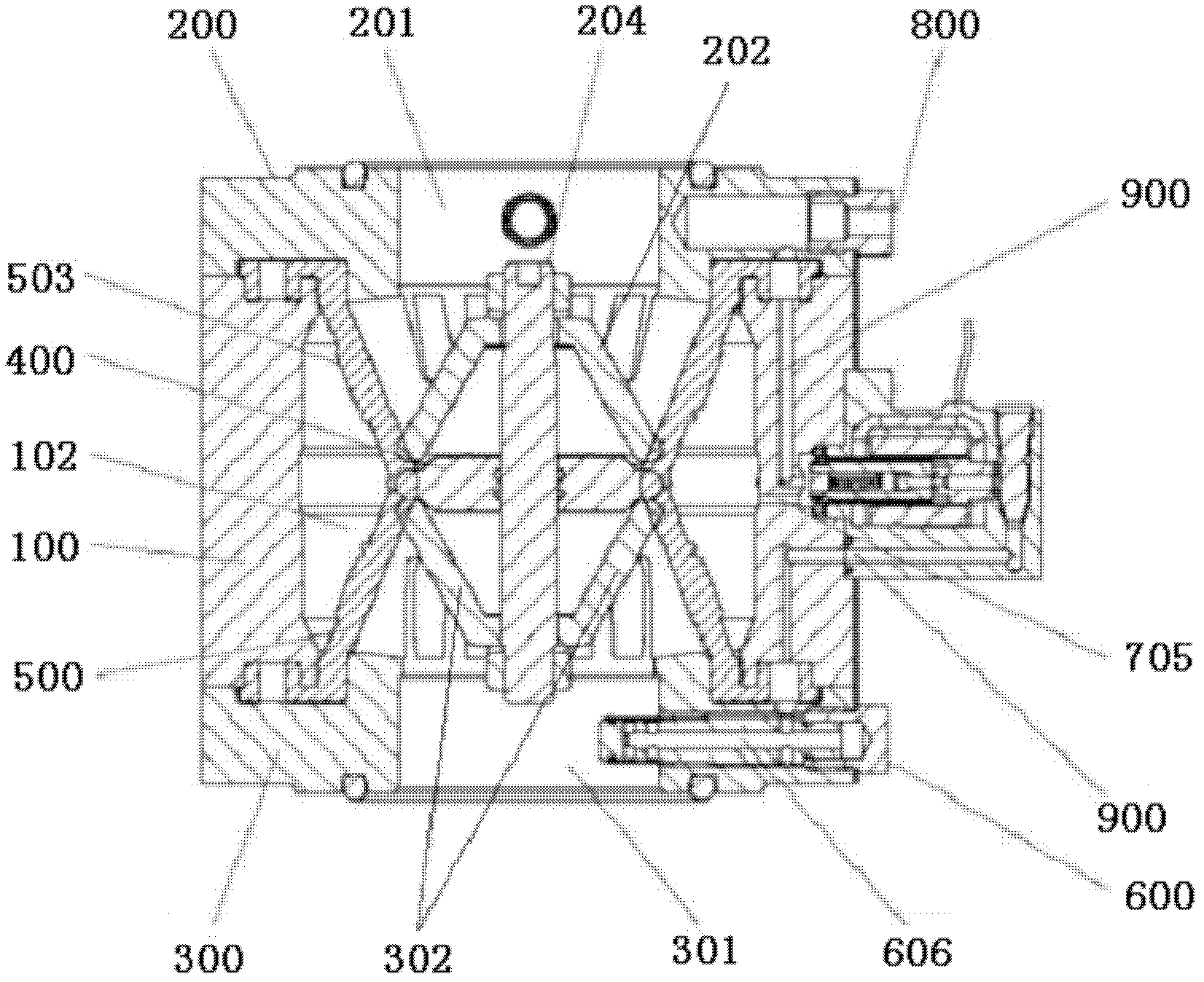

[0034] see figure 1 , 2 , 3, and 4, an energy-saving multifunctional pinch control valve of the present invention includes a valve body 100, an upper end cover 200, a lower end cover 300, an intermediate ring 400, an elastic clamp tube 500, a filter assembly 600, and an electromagnetic coil 700 And quick connector 800;

[0035] see Figure 5 , 6 , 7, the valve body 100 is provided with a hollow cylindrical through hole 101, the upper end of the valve body 100 is affixed to the upper end cover 200, and the lower end of the valve body 100 is affixed to the lower end cover 300;

[0036] see figure 1 , 2 , 3, and 4, the elastic clamp tube 500 is arranged in the through hole 101 of the valve body 100, and the upper and lower ends of the elastic clamp tube 500 are provided with fixed wings 501, 502, and the valve body 100 and the upper end cover 200 The contact part is matched with a housing cavity 102, and the fixed wing 501 at the upper end of the elastic clip tube 500 is en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com