-40 DEG C low-temperature high-strength high-toughness nodular cast iron, preparation method thereof and railway locomotive parts

A technology of nodular cast iron and high toughness balls, applied in the field of railway locomotive parts, to achieve the effects of saving production costs, good inoculation capacity, and avoiding energy and labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0028] The following introduces some of the possible embodiments of the present invention, which are intended to provide a basic understanding of the present invention, but are not intended to identify key or decisive elements of the present invention or limit the scope of protection. It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can propose other alternative implementation modes without changing the essence and spirit of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or restriction on the technical solution of the present invention.

[0029] The application provides the following technical solutions:

[0030] Technical solution 1, a low-temperature high-strength and high-toughness ductile iron at -40°C,...

Embodiment 1

[0053] The preparation method of the nodular cast iron of embodiment 1 may further comprise the steps:

[0054] ① charge preparation: weigh the required amount of pig iron, steel scrap, recarburizer, pure copper, pure nickel, ferrosilicon according to the chemical composition of the nodular cast iron in Example 1, and the addition of the furnace charge is 0% to 50%.

[0055] The pig iron is Q10 pig iron, wherein Mn≤0.06%, P≤0.02%, S≤0.15%, Ti≤0.02%.

[0056] Said steel scrap is pipe trimming scrap, wherein C≤0.2%, Si≤0.2%, Mn≤0.6%, P≤0.15%, S≤0.1%.

[0057] The recarburizer is a crystalline recarburizer calcined and graphitized at a high temperature.

[0058] ②Smelting: first add the steel scrap and recarburizer weighed in step ① into the intermediate frequency furnace, then add pig iron and pure nickel plate, and after all the furnace materials are melted, sprinkle the slag removal agent for molten iron slag removal; when the smelting temperature reaches 1530-1560 Stand sti...

Embodiment 2

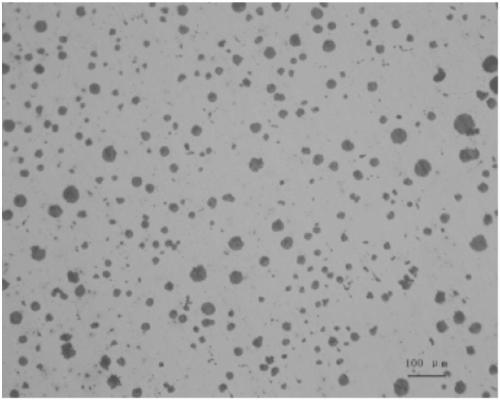

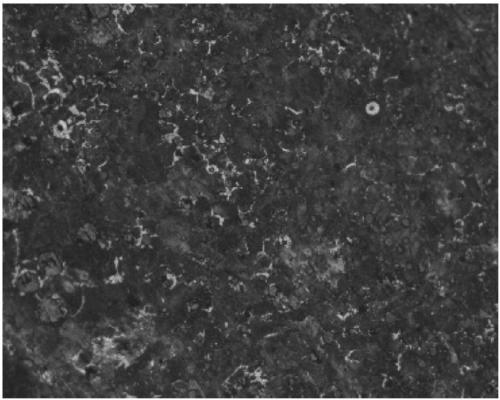

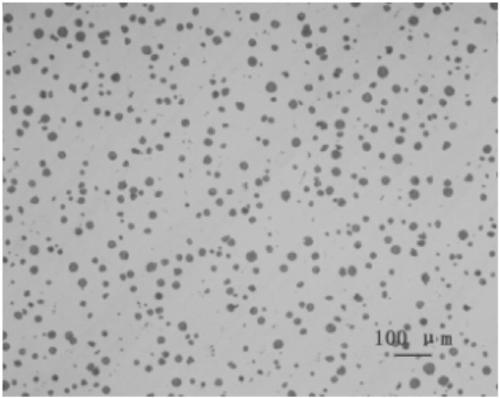

[0082] The matrix structure diagram (95%P+5%F) in the metallographic structure of the 100 times metallographic structure of the nodular cast iron in Example 2 after corrosion is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com