Electric connector

A technology for electrical connectors and contact parts, which is applied in the direction of connections, circuits, and parts of connection devices. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

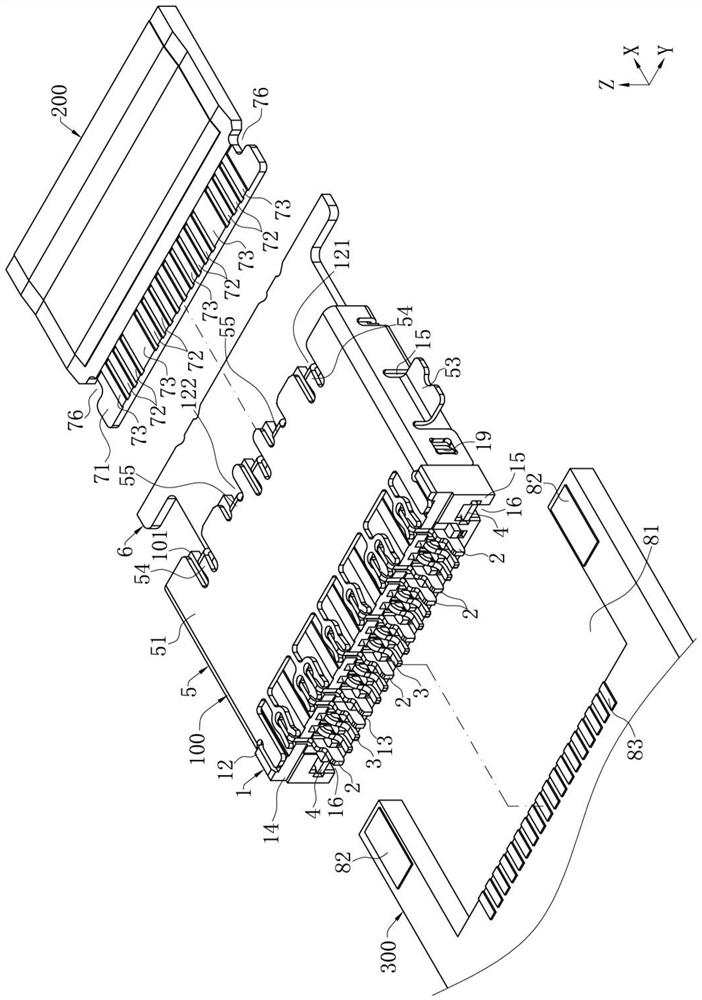

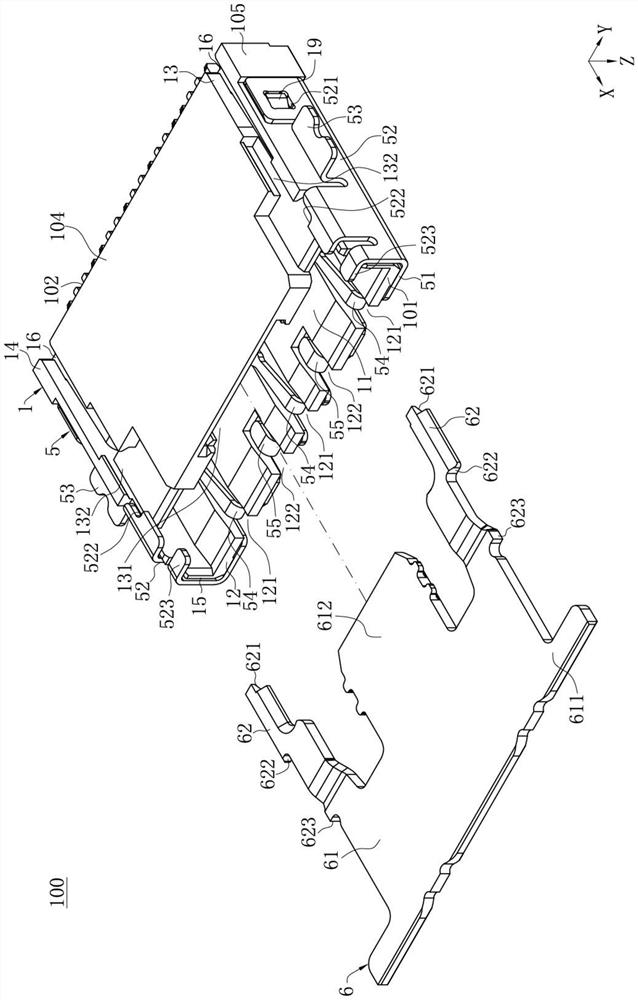

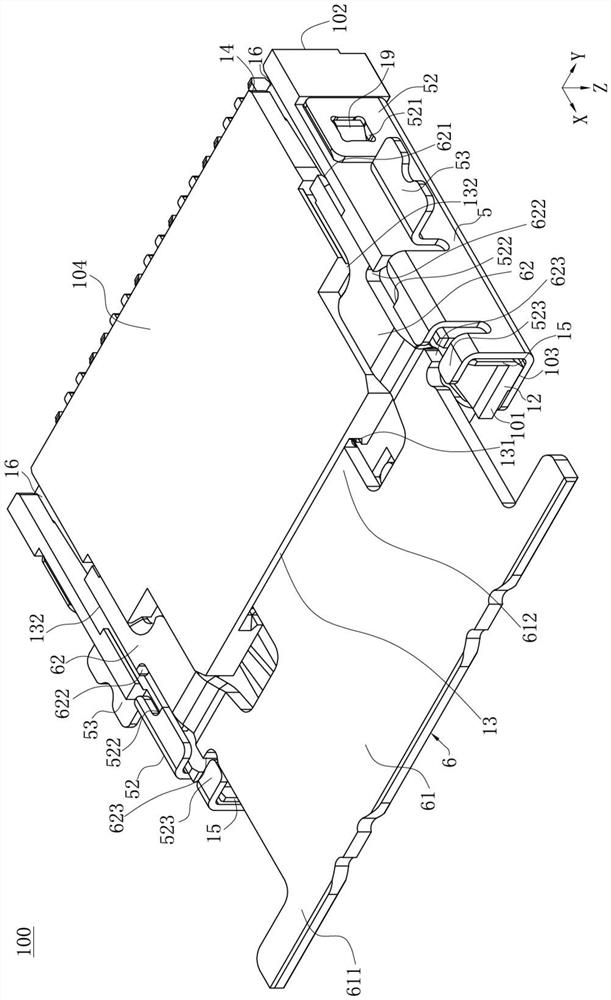

[0059] Such as figure 1 , Figure 4 and Image 6 As shown, the electrical connector 100 of the present invention defines an up-down direction Z, a front-back direction X and a left-right direction Y perpendicular to the up-down direction Z and perpendicular to each other.

[0060] Such as figure 1 , Image 6 and Figure 10 As shown, the electrical connector 100 of the present invention is used for docking with a mating member 200, the electrical connector 100 is installed downward on a circuit board 300, and the mating member 200 is inserted backward into the electrical connector 100 and the two form an electrical connection.

[0061] Such as figure 1 , Figure 4 and Image 6 As shown, the electrical connector 100 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com