A 20x medium-wave continuous zoom lens with an ultra-short non-diffractive surface

A zoom lens and non-diffraction technology, applied in the optical field, can solve the problems of reducing the energy transmittance of the lens, increasing the difficulty and cost of lens processing, reducing the temperature sensitivity of the system, etc., to improve the energy transmittance and system temperature sensitivity, structure The effect of compactness and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

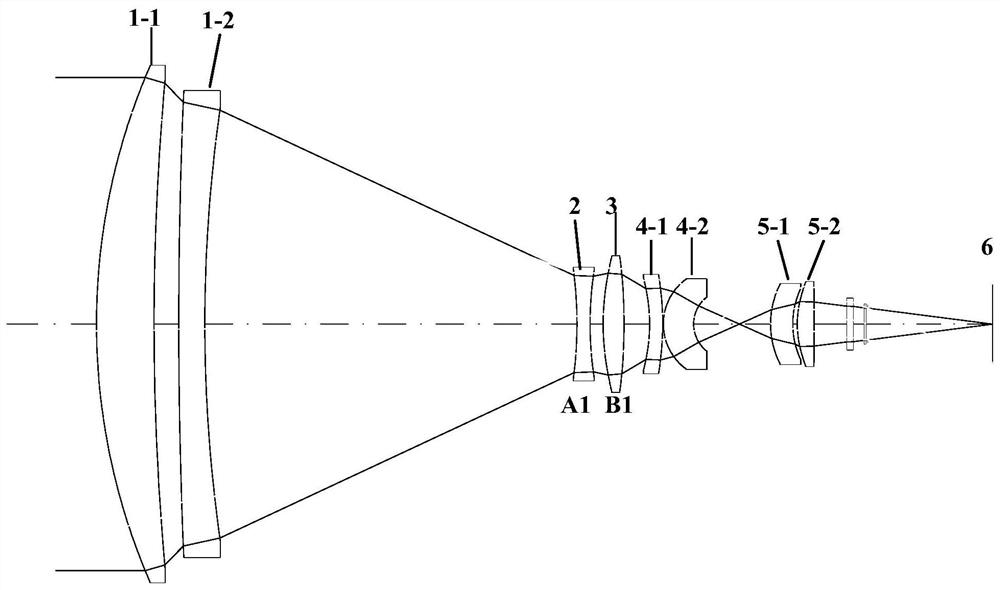

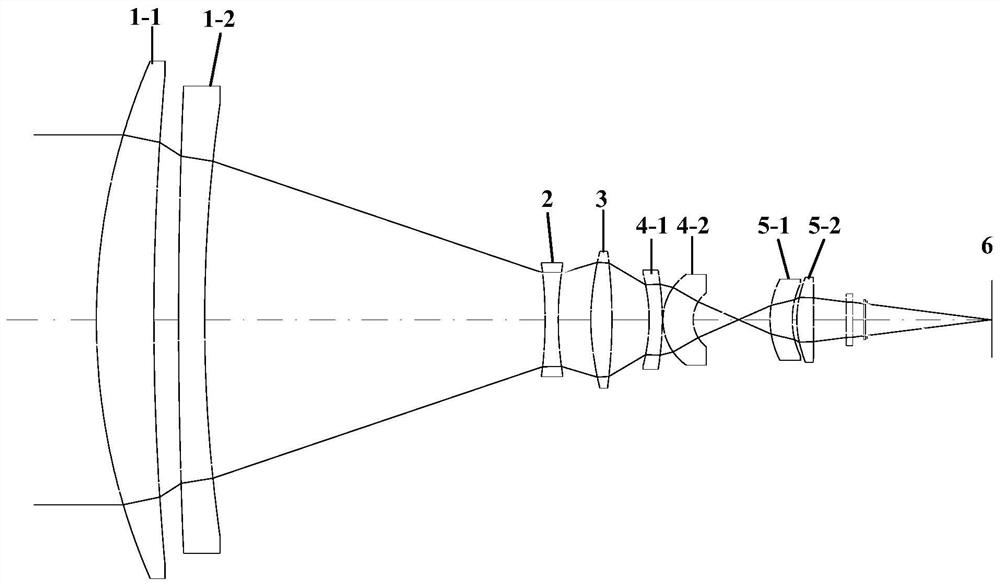

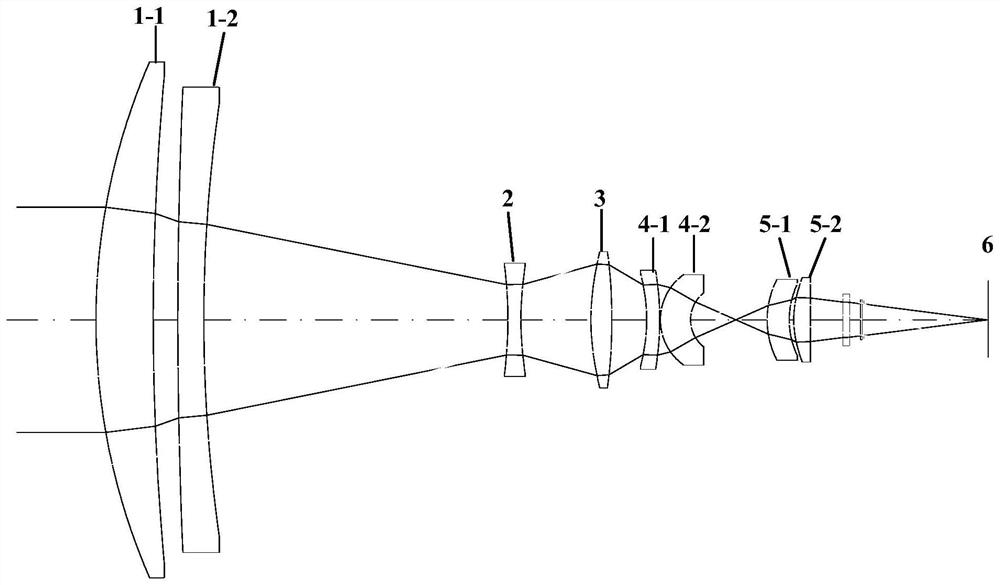

[0034] This embodiment provides an ultra-short non-diffraction surface 20 times medium-wave continuous zoom optical lens, which has an objective lens group 1, a single lens zoom group 2, a single lens compensation group 3, a fixed mirror group 4 and a focusing mirror in sequence along the optical path Group 5: The single-lens zoom group and single-lens compensation group are linked to achieve a large zoom ratio. Through the use of aspheric surfaces and material optimization, advanced aberrations and chromatic aberrations are reduced and the axial space is compressed. In the full field of view and full aperture To obtain satisfactory image quality, the axial space length from the first optical surface to the last optical surface is 110mm.

[0035] The objective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com