Method for recycling and reusing all components of LED-MOCVD (Light Emitting Diode-Metal Organic Chemical Vapor Deposition) preparation process tail gas through pressure swing adsorption in whole temperature process

A technology of pressure swing adsorption and full temperature range, which is applied in separation methods, ammonia preparation/separation, chemical instruments and methods, etc., and can solve the problems such as difficult purification and recovery of H2/NH3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

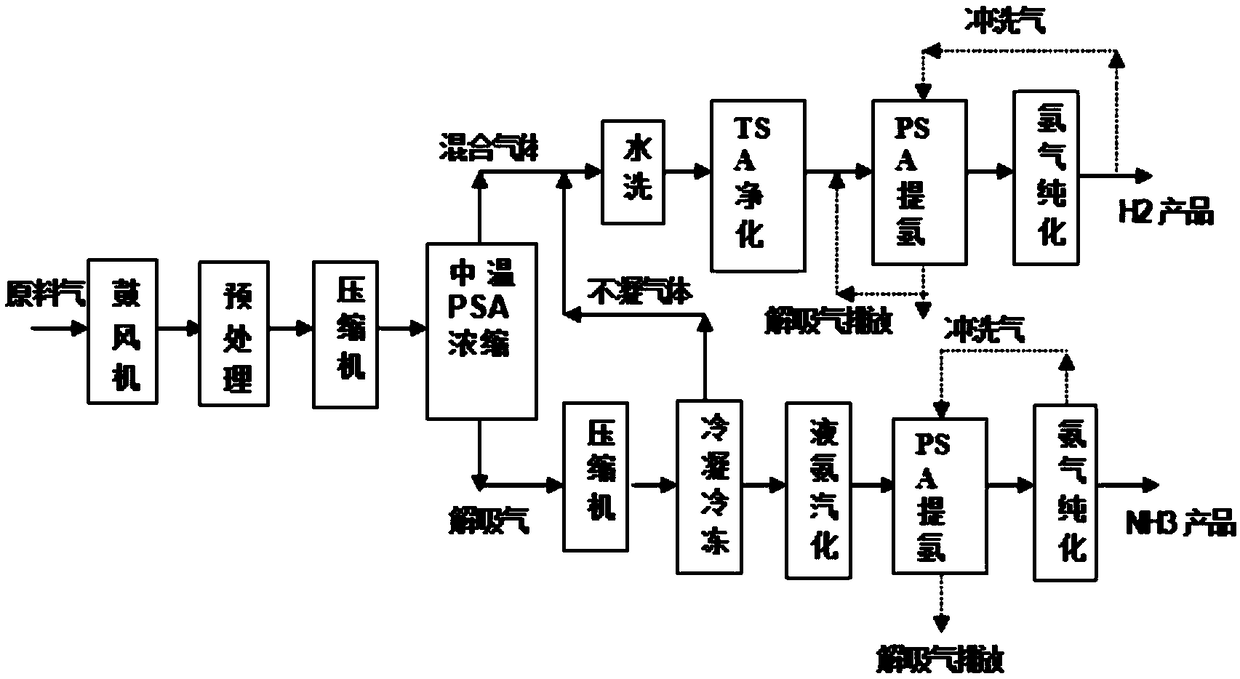

[0057] Such as figure 1 As shown, a LED-MOCVD process exhaust gas full temperature range pressure swing adsorption full component recovery and reuse method, the raw material gas, that is, normal pressure or low pressure MOCVD (metal oxide chemical vapor deposition) preparation based on gallium nitride (GaN) The exhaust gas in the light-emitting diode (LED) process grown on epitaxial wafers is mainly composed of nitrogen (N2): 46% (v / v, the same below), hydrogen (H2): 34%, ammonia (NH3): 19% , the remaining 1% is a small amount of metal ions, particles, arsine, methane (CH4), water (H2O), carbon monoxide (CO), carbon dioxide (CO2), oxygen (O2) and other impurity components, the pressure is normal pressure, The temperature is 50-70°C, and the specific implementation steps include:

[0058] (1) Pretreatment, the raw material gas is sent to the pretreatment unit consisting of a dust collector, a particle filter, and an oil mist collector through a blower. Under the operating cond...

Embodiment 2

[0069] Such as figure 1 As shown, on the basis of Example 1, the raw material gas temperature is 20-30°C, and the rest remain unchanged. The high-temperature product gas generated in the hydrogen purification process is heat-exchanged with the raw material gas to restore its temperature to 50-70°C, and Carry out operation by embodiment 1. The purpose is to prevent the high concentration of ammonia in the raw gas from easily escaping into liquid at a temperature of 20°C lower than the ambient temperature and damaging the equipment in the pretreatment process.

Embodiment 3

[0071] Such as figure 1 As shown, on the basis of Example 1, the raw material gas temperature is 100-120°C, and the rest remains unchanged, and the normal operation can be directly carried out as in Example 1, wherein the pretreated raw material gas is pressurized to 3.0MPa, and the pressure is changed at medium temperature. The operating pressure of the adsorption (PSA) concentration process is 3.0MPa, and the operating temperature is 100-120°C; the intermediate gas from the medium-temperature pressure swing adsorption (PSA) concentration process and the non-condensable gas from the condensation and freezing process are mixed and then washed with water The operating pressure of the water washing tower is 2.0-2.4MPa, and the operating temperature is 70-90°C; the operating pressure of the temperature swing adsorption purification and pressure swing adsorption hydrogen extraction process is 2.0-2.4MPa, and the operating temperature is 70-90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com