Alkane and silane reaction chlorine-based SiC-CVD epitaxial process tail gas FTrPSA recovery method

A recovery method and technology of silane, applied in separation methods, chemical instruments and methods, organic silicon compounds, etc., can solve the problems of high preparation cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

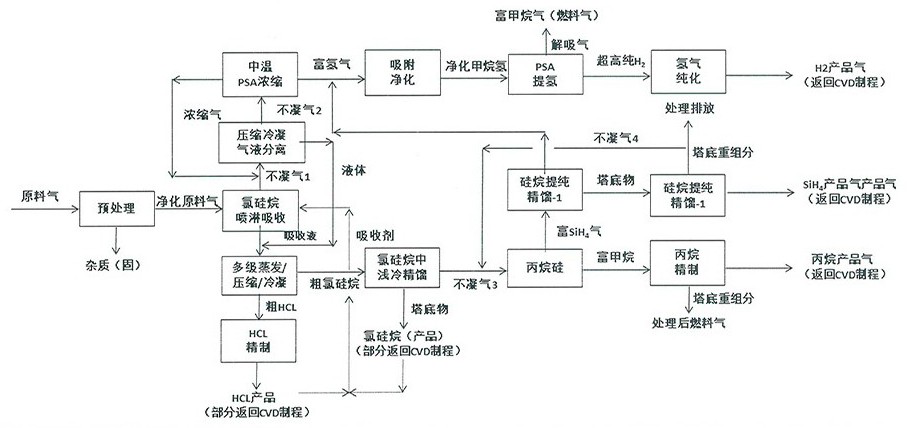

[0051] Such as figure 1 As shown, a chlorine-based SiC-CVD epitaxial system tail gas FTrPSA recovery and method for the reaction of alkane and silane, the specific implementation steps include,

[0052] (1) Raw material gas, with propane (C3H8) as the main carbon (C) source, silane (SiH4) as the silicon (Si) source and adding hydrogen chloride (HCl) for chemical vapor deposition (CVD) preparation based on silicon carbide (SiC ) The tail gas in the chlorine-based epitaxy growth process, its main components are hydrogen (H2), HCl, C3H8, methane (CH4), SiH4, chlorosilane (SiHmCln), and trace amounts of carbon monoxide (CO), carbon dioxide (CO2), ethyl Alkanes and light hydrocarbon components above carbon 2 and higher hydrocarbons (C2+), chloroalkanes (CHmCln), water (H2O) and silicon dioxide (SiO2), Si / C fine particles, normal pressure and temperature.

[0053] (2) Pretreatment, the raw material gas is pressurized and sent to the pretreatment unit consisting of a dust collector,...

Embodiment 2

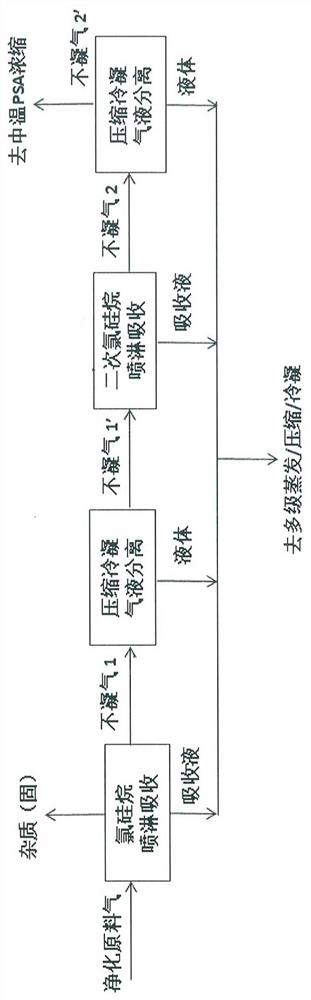

[0065] Such as figure 2 As shown, on the basis of Example 1, under the condition that the concentration of HCl and chlorosilane contained in the purified raw gas is relatively high, such as the total concentration of chlorine is greater than 5%, the chlorosilane spray absorption process can add a secondary chlorosilane spray The non-condensable gas 1' from the chlorosilane spray absorption process is compressed, condensed, and gas-liquid separated, and the formed non-condensable gas 1' is pressurized to 0.6~0.8MPa, and the cold and heat are exchanged to 80 After ~200°C, it enters from the bottom of the absorption tower in the additional secondary chlorosilane spray absorption process, uses a mixed liquid containing chlorosilane / HCl as the absorbent, and sprays down from the top of the secondary spray absorption tower with non-condensable gas 1 'Reverse mass transfer exchange is carried out, the absorption liquid enriched with chlorosilane and HCl flows out from the bottom of ...

Embodiment 3

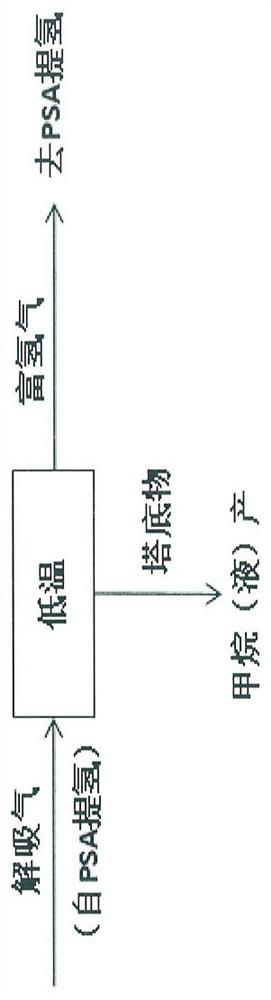

[0067] Such as image 3 As shown, on the basis of Example 1, the desorbed gas from the pressure swing adsorption hydrogen extraction process enters the cryogenic rectification tower after being condensed, methane flows out from the bottom of the rectification tower with liquid as the product, and the non-condensable gas is hydrogen-rich gas. After cold and heat exchange, return to the pressure swing adsorption hydrogen extraction process to further recover H2. At this time, the yield of H2 product gas is higher than 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com