Method for producing coating

A production method and coating technology, applied in the direction of coating, etc., can solve the problems of unfavorable continuous mechanized production, poor airtightness, and increased labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

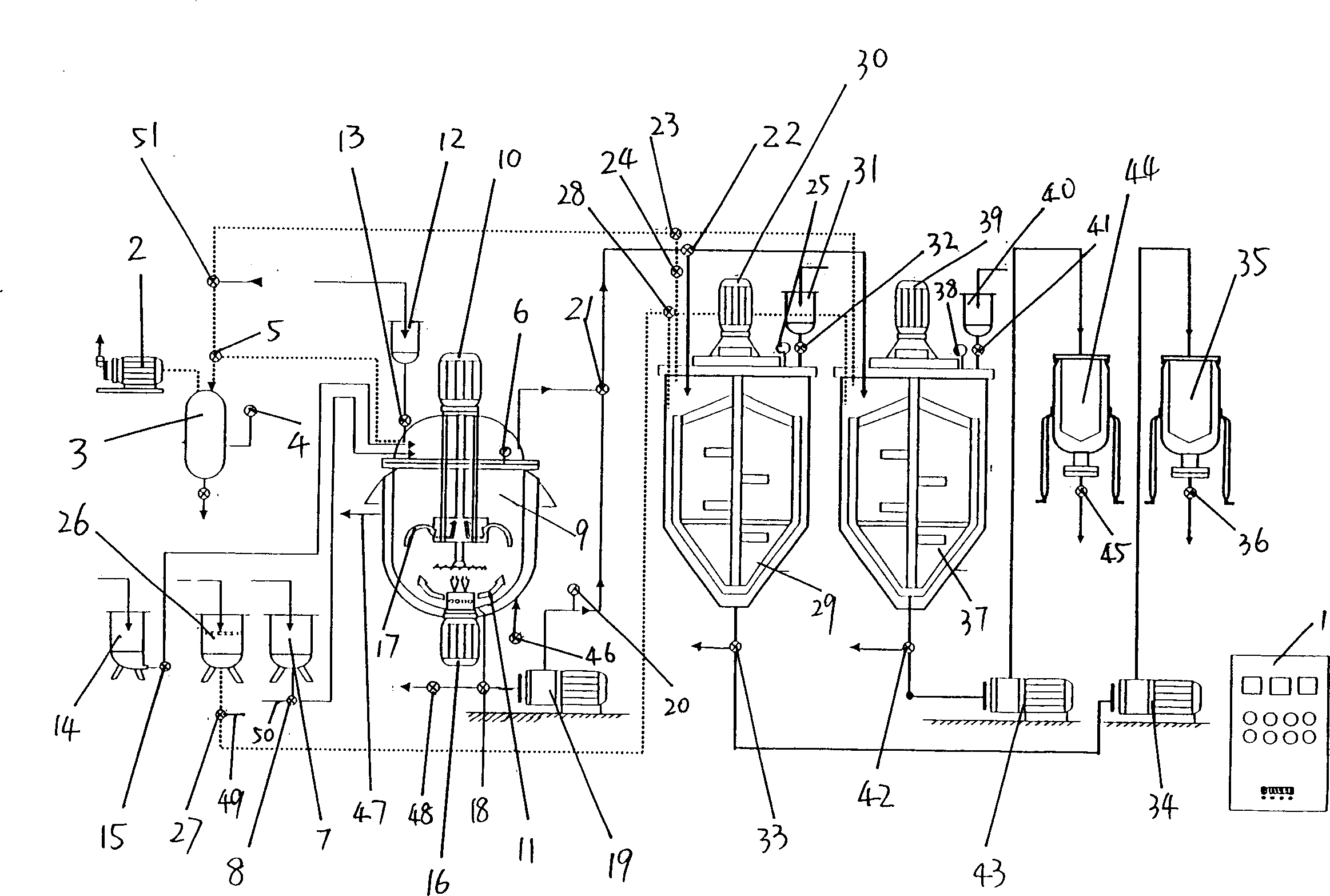

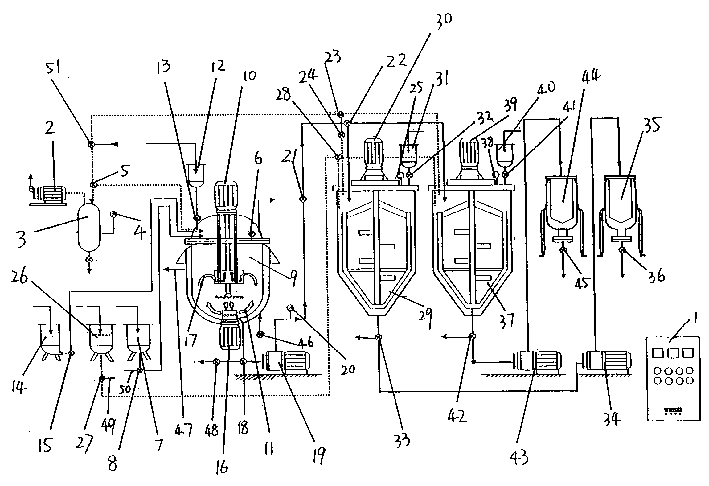

[0006] In the figure, 1 is the electrical control panel, 2 is the vacuum pump, 3 is the vacuum buffer pump, 4 is the vacuum pressure gauge, 5 is the negative pressure three-way distribution valve, 6 is the vacuum pressure gauge of the dispersing tank, 7 is the liquid feeding tank, and 8 is the liquid Feeding valve (three-way valve), 9 is dispersing, shearing, emulsifying grinding kettle, 10 is high-speed dispersing, basket sand mill unit, 11 is dispersing blade, 12 is additive feeding tank, 13 is additive feeding valve, 14 is Powder feeding tank, 15 is a powder feeding valve, 16 is a high shear emulsifier, 17 is a basket mill, 18 is a pipeline type multi-stage wet mill feed valve (three-way valve), 19 is a pipeline type multi-stage Wet mill, 20 is a pressure gauge, 21 is a slurry inlet valve (three-way valve), 22 is a slurry distribution valve (three-way valve), 23 is a vacuum distribution valve, 24 is a vacuum control valve for a paint mixing tank, 25 is the vacuum pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com