Liquid-based thin-layer cell sheet production clamp

A thin-layer cell and liquid-based technology, applied in the field of vertical slide clips, can solve the problem of cell collection on unfavorable glass slides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

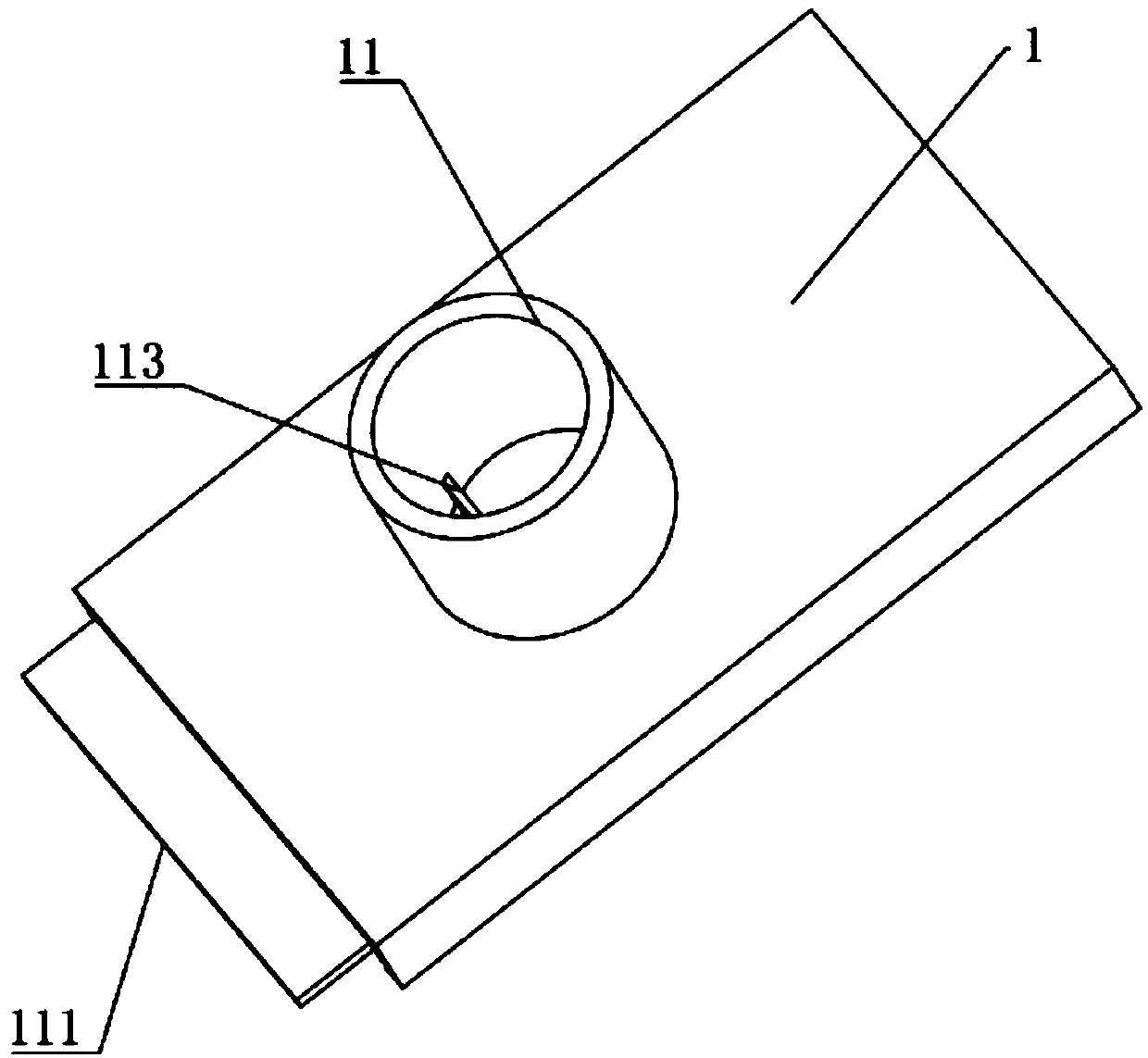

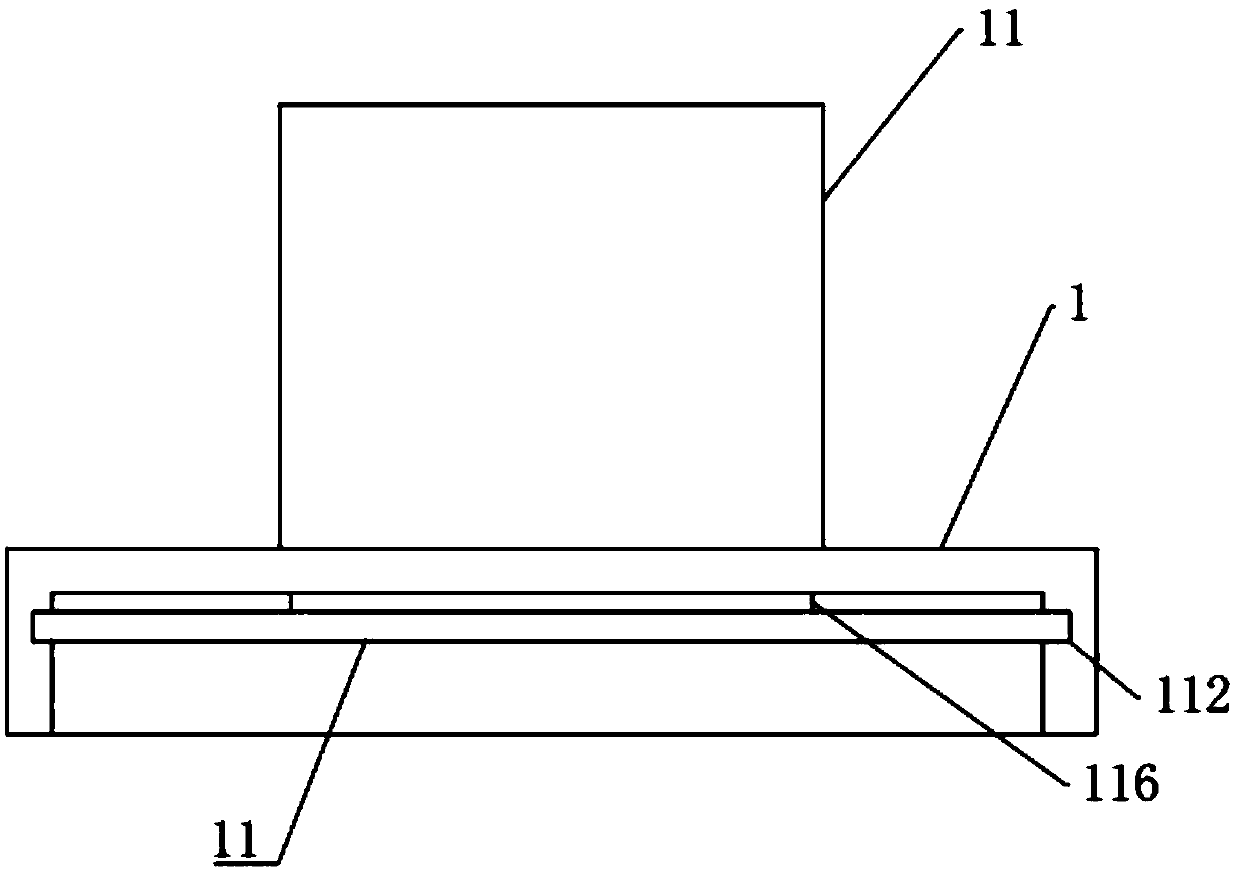

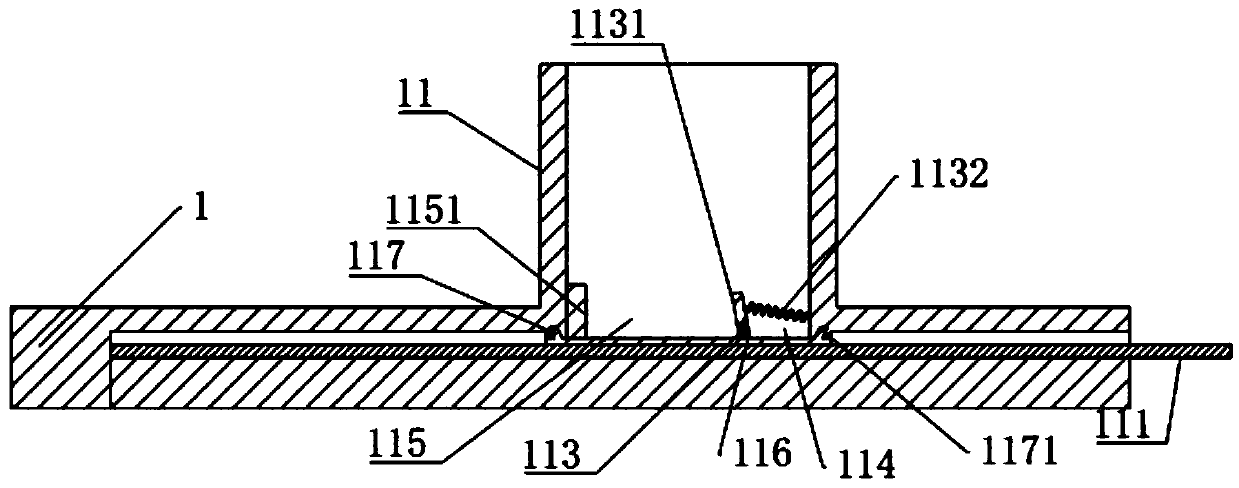

[0034] Embodiment 1: A kind of liquid-based thin-layer cell slide clip, such as figure 1 with image 3 As shown, it includes a fixed seat 1 and a settling tube 11 vertically arranged on the fixed seat 1, the bottom of the settling tube 11 communicates with the fixed seat 1, and an annular groove 117 is provided at the lower end of the settling tube 11, and an annular groove 117 is provided on the groove wall. There is an inclined surface 1171 extending from the lower end of the settling tube 11 to the direction away from the axis of the settling tube 11, and a sealing rubber ring 116 is fixed in the ring groove 117, so that when the film-making clamp is in a centrifugal state, the cell and the water channel are restricted outside the settling tube 11; Offer slot 112 respectively on seat 1 two side walls (as figure 2 As shown), the slot 112 is slidingly connected with a slide 111, and the slide 111 is provided with a placement groove 1111 for the settling tube 11 to embed on th...

Embodiment 2

[0036] Embodiment 2: a kind of liquid-based thin-layer cell slide clip, the difference from embodiment 1 is that, as Figure 5 As shown, a filter cup 118 is sleeved in the settling tube 11, a limit block 1184 is provided on the outer wall of the filter cup 118, and a limit groove 11841 for the limit block 1184 to slide in is provided on the settling tube 11 inner wall, and the limit The cooperation of the block 1184 and the limit groove 11841 limits the rotation of the filter cup 118 in the settling tube 11; the opening of the filter cup 118 is provided with an outwardly extending support plate 1181, and the support plate 1181 limits the filter cup 118 along the settling tube 11 Move down; the bottom of the filter cup 118 is provided with a through hole 1182 at the position directly above the cell sedimentation area 114, and a filter membrane 11821 for closing the through hole 1182 is provided on the wall of the through hole 1182, and the filter membrane 11821 is set to filter ...

Embodiment 3

[0037] Embodiment 3: A kind of liquid-based thin-layer cell slide clip, the difference from Embodiment 1 is that, as Figure 6 As shown, slide grooves 1191 parallel to the slots 112 are respectively provided on the two side walls of the fixing seat 1, and a pressing plate 119 that is slidingly connected with the sliding groove 1191 is provided at the lower end of the glass slide, and a pressing plate 119 is provided on the pressing plate 119 to connect upwardly. Squeeze the pressing block 1192 of the glass slide so that the lower end of the slide 111 and the settling tube 11 are closely attached to ensure that the liquid-based cells on the slide 111 are always in the settling tube 11 when the slide is clamped in a centrifugal state. Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com