Production method of fiber reinforced cement composite concrete prefabricated building elements

A fiber-reinforced cement and building component technology, which is applied in building components, building structures, buildings, etc., can solve the problems of popularization of precast concrete wall panels, hindering market development prospects, and single surface decoration effects, etc., to achieve favorable products Quality, excellent moldability, texture and rich color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

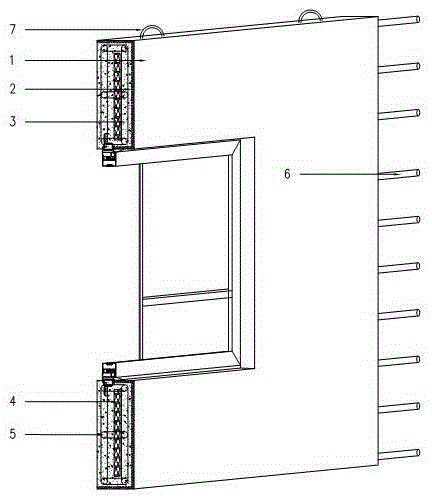

Image

Examples

Embodiment 1

[0069] 1) Mix 22kg (22%) of cement, 30kg (30%) of sand, 21kg (21%) of glass crumbs, 5kg (5%) of liquid pigment, 1kg (1%) of carbon fiber, 1kg (1%) of PU fiber, Dispersed latex powder 5kg (5%), water reducing agent naphthalene sulfonate formaldehyde condensate 1.5kg (1.5%), early strength agent sulfate 0.5kg (0.5%), antifreeze agent calcium chloride 0.5kg (0.5%), Set retarder citric acid 0.5kg (0.5%), metakaolin 3kg (3%), fly ash 2kg (2%), water 7kg (7%) and mix well to make decorative surface mortar,

[0070] 2) Prepare the prepared decorative surface layer mortar, use the spray method to make a decorative surface layer in a wooden mold with decorative effect, and cure it naturally for 10 minutes;

[0071] 3) Put 25kg (25%) of cement, 50kg (50%) of sand, 5kg (5%) of alkali-resistant glass fiber, 5kg (5%) of dispersible latex powder, and 1.5kg of water reducing agent naphthalenesulfonate formaldehyde condensate ( 1.5%), early strength agent sulfate 0.5kg (0.5%), antifreeze age...

Embodiment 2

[0080] (1) Sulfonate 48kg (48%) of cement, 11kg (11%) of fine stones, 11kg (11%) of ceramic debris, 4kg (4%) of powdered pigment, 4kg (4%) of polypropylene emulsion, and water reducer Melamine formaldehyde condensate 1.5kg (1.5%), early strength agent nitrite 0.5kg (0.5%), antifreeze agent potassium carbonate 0.5kg (0.5%), water 20kg (20%) and mix well to make decorative surface layer mortar ,

[0081] 2) Prepare the prepared decorative surface layer mortar, and use the brushing method to make a decorative surface layer in a steel mold with a decorative effect, and let it cure naturally for 30 minutes;

[0082] 3) Mix cement 50kg (50%), sand 20kg (20%), basalt fiber 1kg (1%), polypropylene emulsion 4kg (4%), water reducer sulfonated melamine formaldehyde condensate 1kg (1.5%), early strength 0.5kg (0.5%) of antifreeze nitrite, 0.5kg (0.5%) of antifreeze potassium carbonate, 3kg (3%) of mineral powder, and 20kg (20%) of water are mixed according to the following weight percent...

Embodiment 3

[0091] 1) Stir 25kg (25%) of cement, 40kg (40%) of sand, 20kg (20%) of metal debris, 1kg (1%) of PVA fiber, 2kg (2%) of mineral powder, and 12kg (12%) of water After that, it is made into decorative surface mortar,

[0092] 2) Make the decorative surface layer mortar with the prepared decorative surface layer in the FRP mold with decorative effect by laying vibration method, and let it cure naturally for 60 minutes;

[0093] 3) Mix 42kg (42%) of cement, 38kg (38%) of sand, 2kg (2%) of alkali-resistant glass fiber, 2kg (2%) of PVA fiber, and 16kg (16%) of water according to the following weight percentage ratio, Stir evenly to make fiber reinforced cement (FRC) slurry.

[0094] 4) After the above-mentioned fiber reinforced cement (FRC) slurry is prepared, it is poured into the FRP mold with a decorative surface layer, and then rolled and compacted with a pressure roller to form a fiber reinforced cement (FRC) layer.

[0095] 5) After the fiber-reinforced cement FRC layer has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com