Partially prefabricated double-layer steel reinforced concrete L-shaped column

A prefabricated assembly and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of environmental pollution, long time-consuming cast-in-place concrete columns, and difficulties in hoisting and transportation of fully precast concrete columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

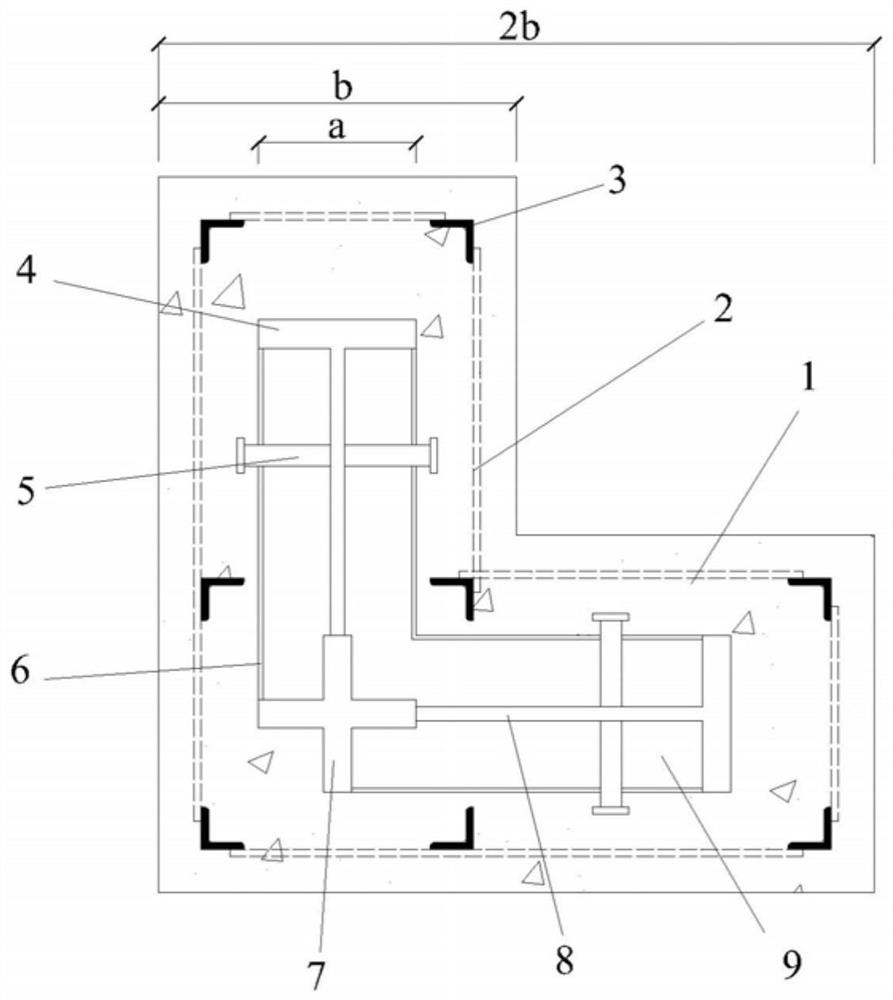

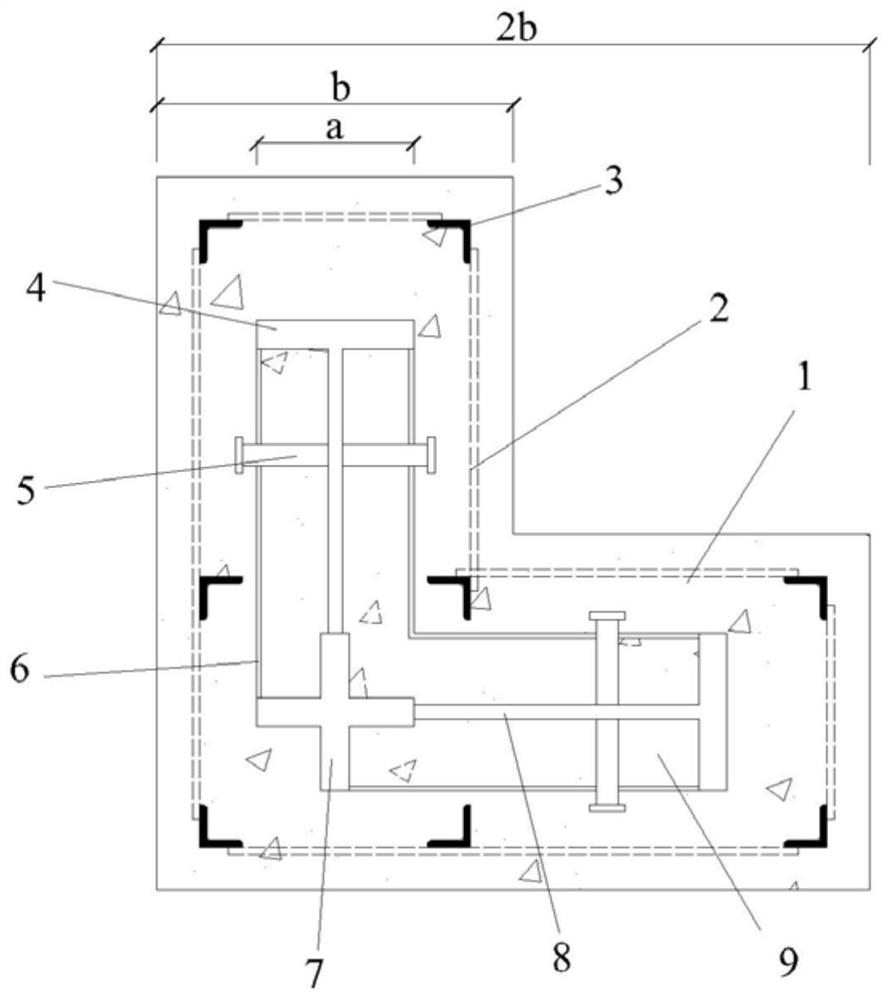

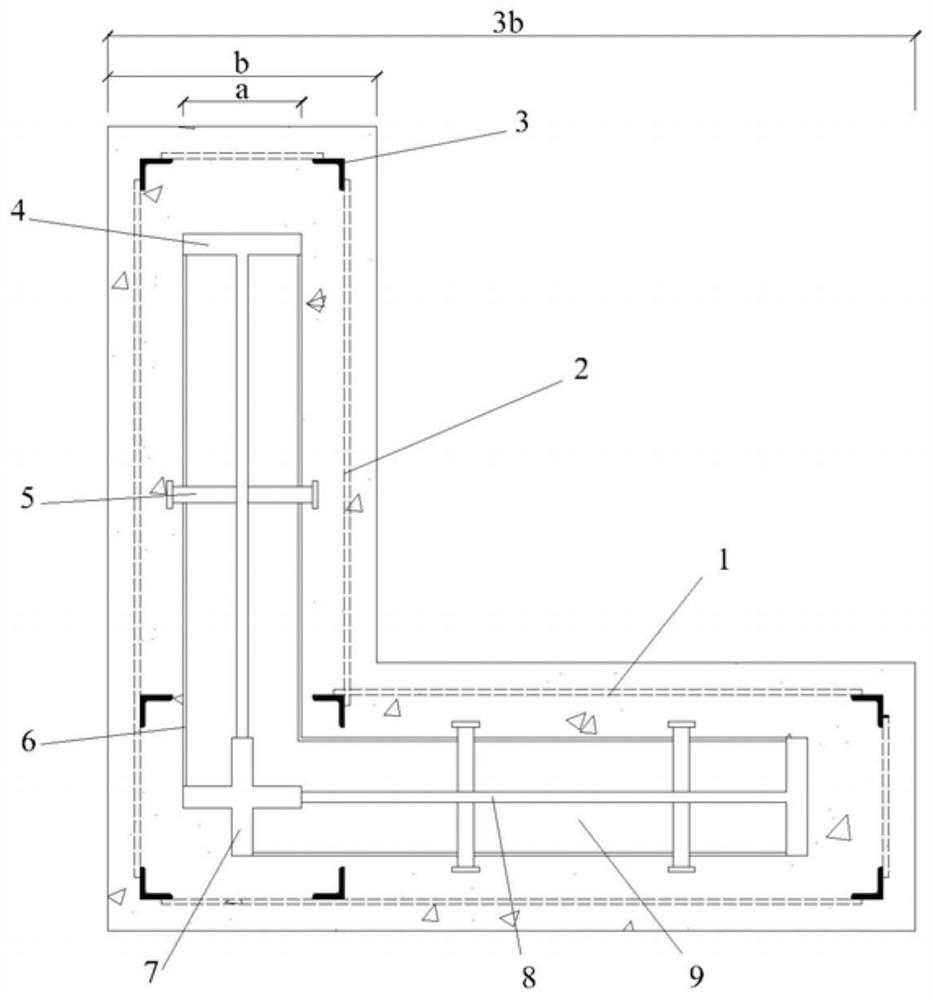

[0040] refer to figure 1 , figure 2 As shown, the partially prefabricated and assembled double-layer reinforced concrete L-shaped column section includes a partially prefabricated and assembled double-layer reinforced concrete L-shaped column shell, and a steel skeleton inside the L-shaped column shell, and the L-shaped column shell includes precast concrete 1 and shaped steel Skeleton; steel skeleton includes outer hollow type steel ( Figure 8 ) and the inner solid web section steel ( Figure 7 ); the solid-belly L-shaped section steel of the inner layer includes a cross-shaped section steel 7 and section steel webs 8 connected to its two limbs, the other end of the section steel web...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com