Partially prefabricated steel reinforced concrete T-shaped column with embedded column

A prefabricated concrete and prefabricated assembly technology, applied in columns, piers, pillars, etc., can solve the problems of self-heavy components, poor integrity, and high transportation and hoisting costs, reducing raw material costs, facilitating construction, and reducing transportation and hoisting costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

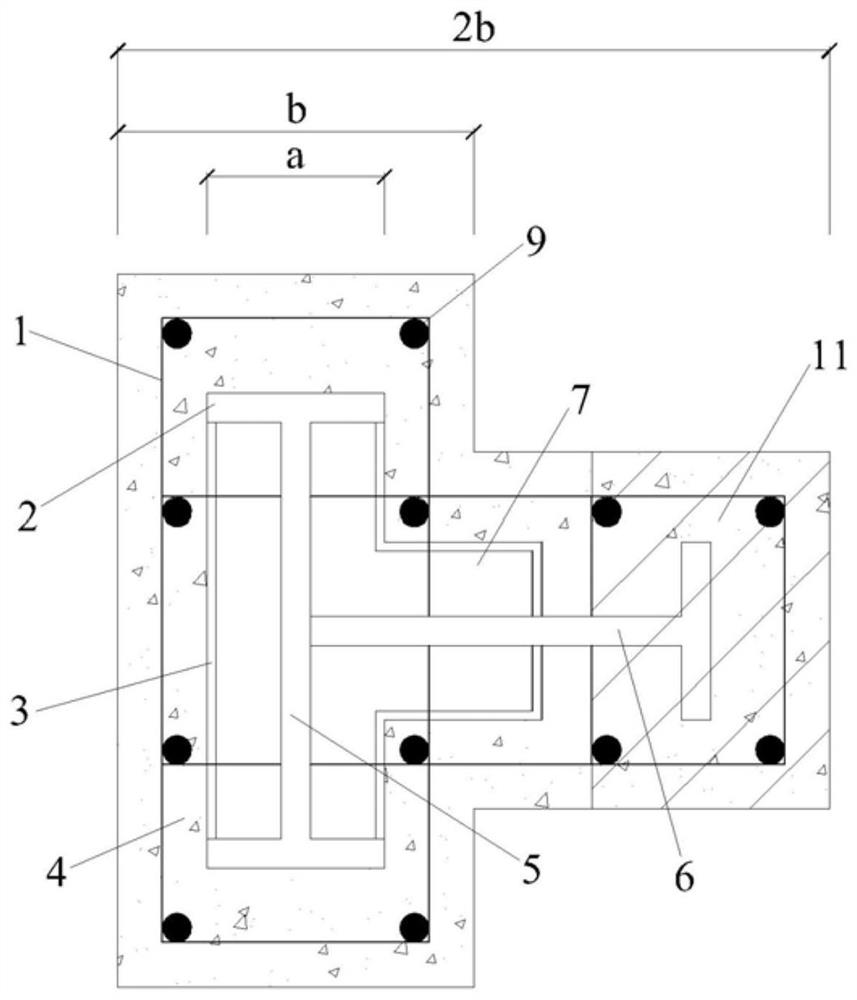

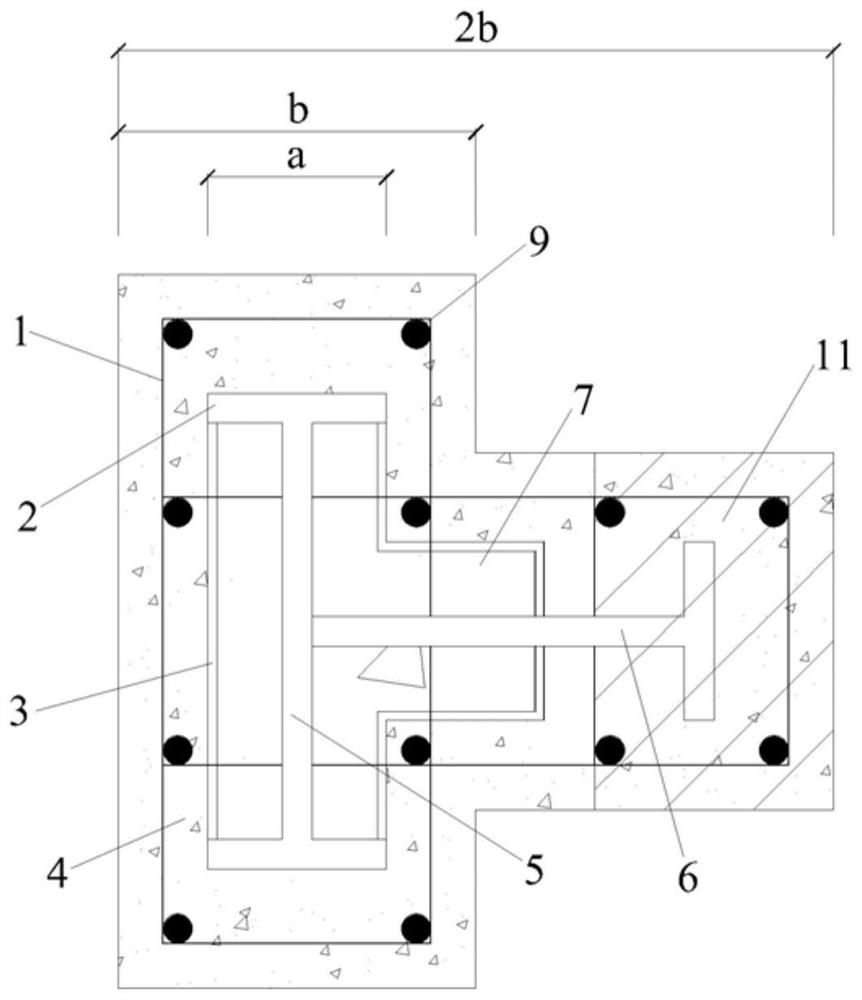

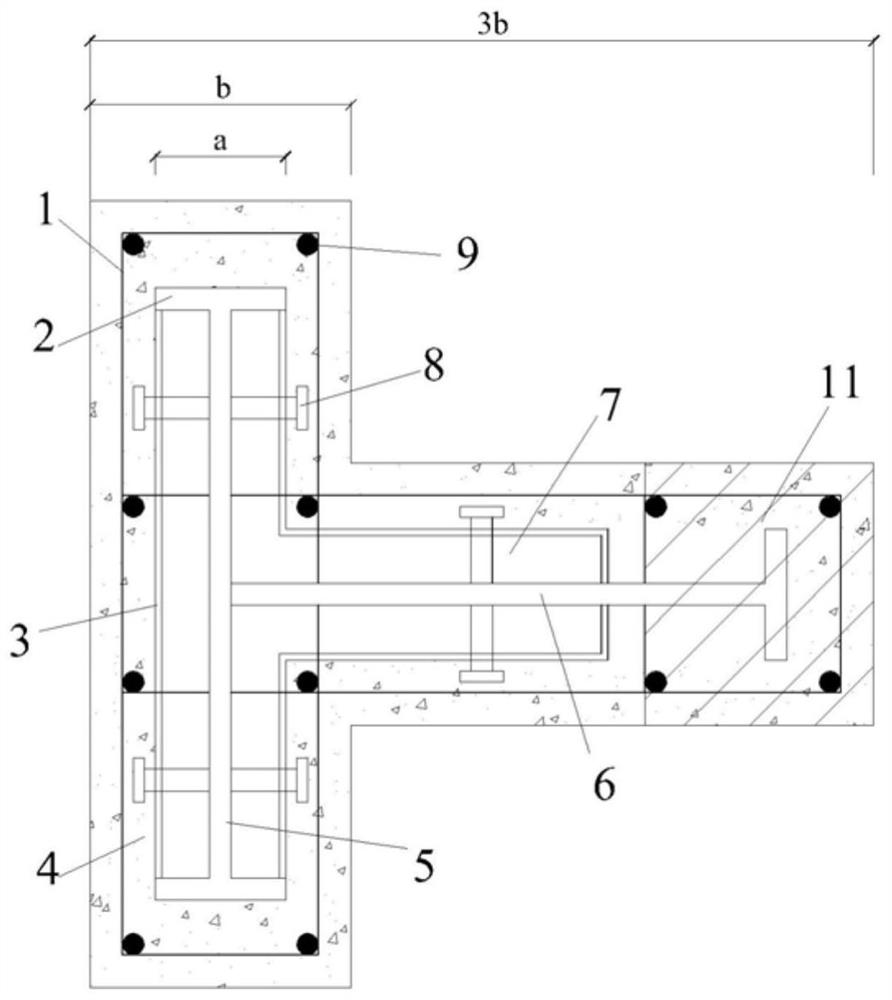

[0036] refer to figure 1 , figure 2 As shown, the partially prefabricated steel concrete T-column with concealed column provided by the embodiment of the present invention includes a partially prefabricated steel concrete T-column shell with concealed column ( figure 1 ), and the internal cast-in-place concrete 10, partly prefabricated steel concrete T-column shell with concealed column ( figure 1 ) includes prefabricated concrete 4 and T-shaped steel-steel skeleton, T-shaped steel-steel skeleton is made up of longitudinal bar 9, stirrup 1 and T-shaped steel, T-shaped steel includes flank steel plate 2 and the shaped steel web that is T-shaped distribution, The shaped steel webs include a first shaped steel web 5 and a second shaped steel web 6, which are vertically connected to each other in a T-shape. The flank steel plate 2 is fixed on one end of the second shaped st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com