Partially prefabricated high-strength steel reinforced concrete cross-shaped column

A prefabricated assembly and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of difficult lifting and transportation, pollution of the environment, etc., and achieve the effects of reducing transportation and lifting costs, enhancing bonding, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

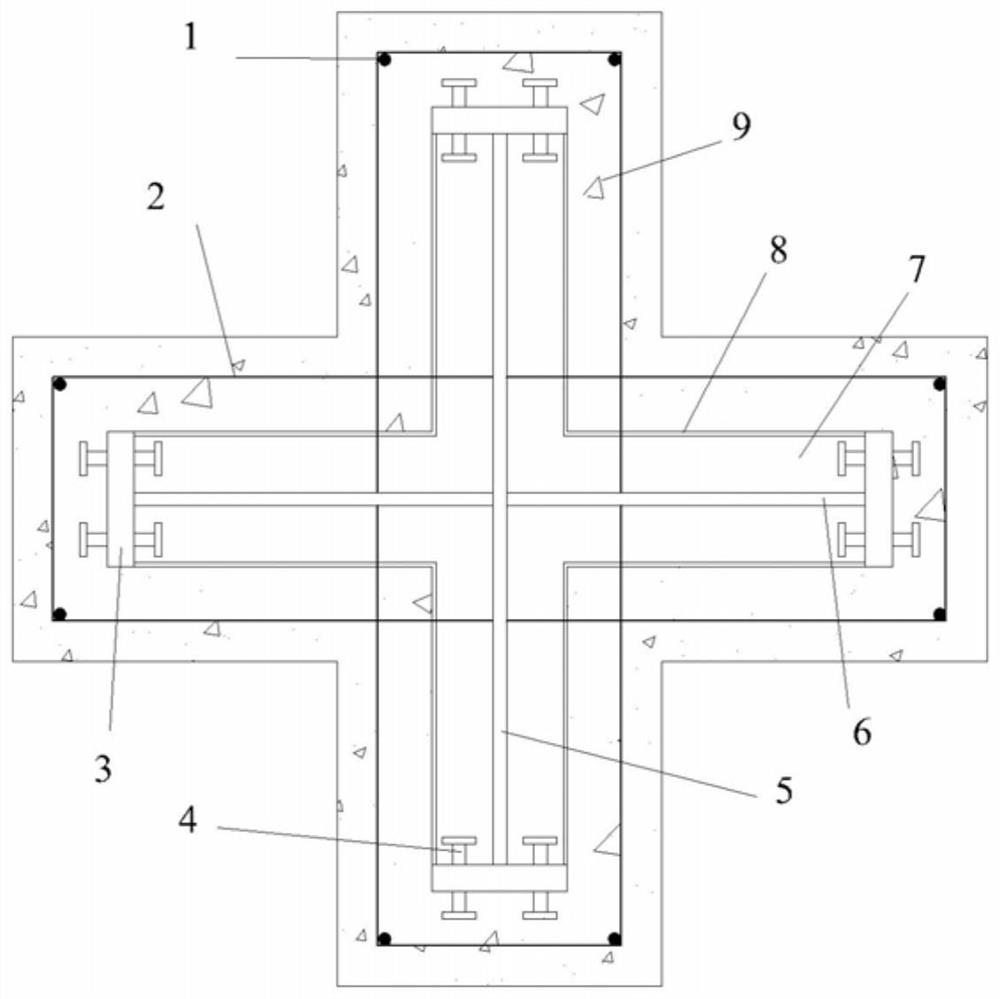

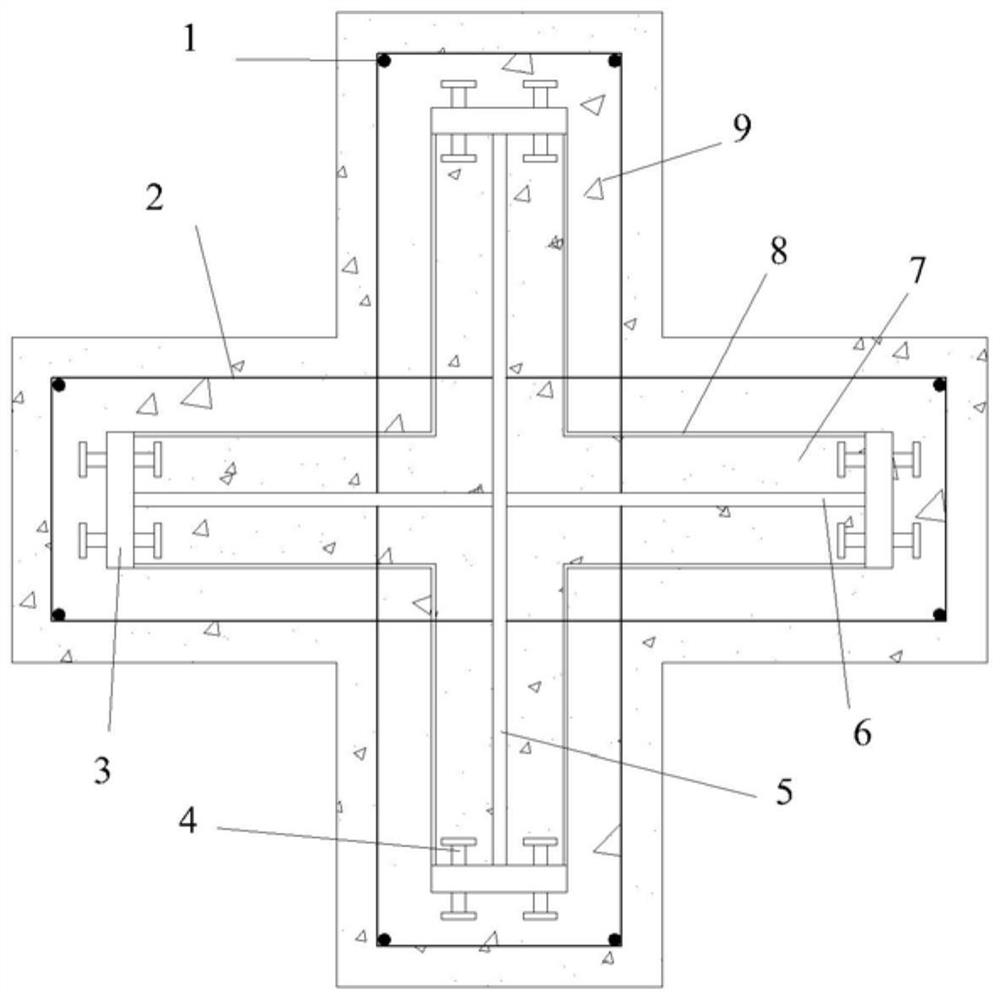

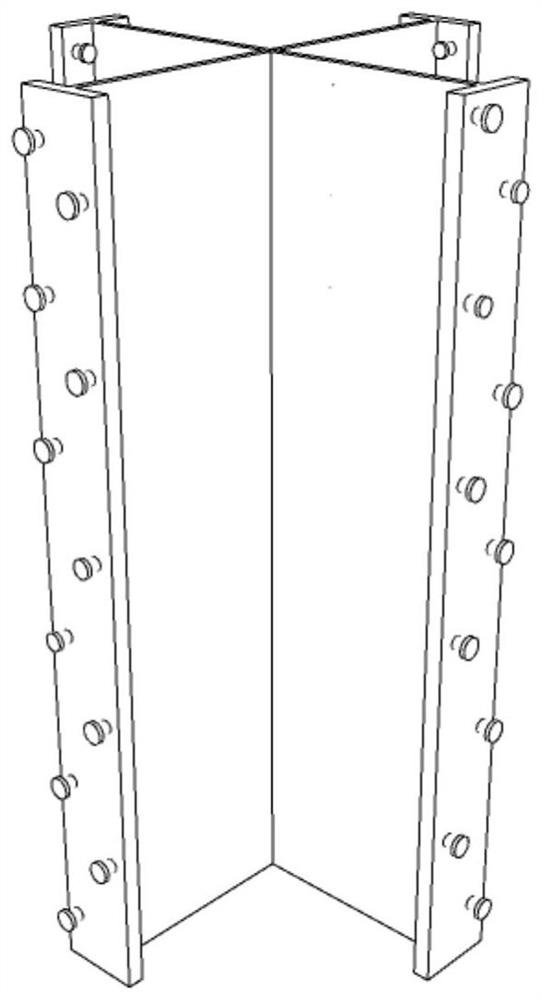

[0026] refer to figure 1 , figure 2 As shown, the partially prefabricated high-strength steel concrete cross-shaped column includes the partially prefabricated high-strength steel concrete cross-shaped column shell ( figure 1 ), and the internal cast-in-place concrete 10, partly prefabricated high-strength steel concrete cross-shaped column shell ( figure 1 ) includes prefabricated concrete 9 and cross-shaped steel-steel skeleton. The cross-shaped steel-steel skeleton includes cross-shaped steel surrounded by longitudinal bars 1 and stirrups 2. The cross-shaped steel web includes the first steel web 5 and the second steel web 6, the second steel web 6 is vertically welded on both sides of the first steel web 5, and the side wing steel plate 1 is vertically welded on the first steel web 5 and the two ends of the second shaped steel web 6, and at the same time, pegs 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com