Pile body (or column body) concrete vibrating rod lifting device and construction method thereof

A technology of concrete and vibrating rods, which is applied in sheet pile walls, foundation structure engineering, erection/assembly of bridges, etc., can solve the problems of large safety hazards and low efficacy, and achieve the effects of eliminating air bubbles, fast speed, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

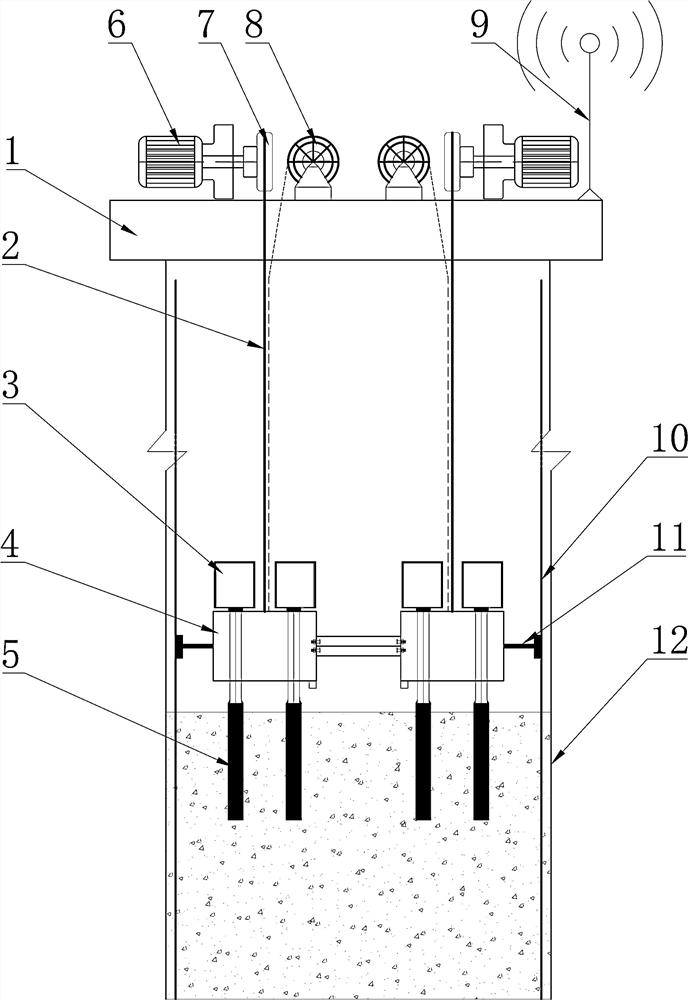

[0039] Such as Figure 1~4 As shown, the lifting device for the concrete vibrating rod of the pile body includes a beam 1, which is used to place the opening position above the formwork frame 12. The beam 1 is provided with a plurality of winches 6, and is also provided with a plurality of counterweight vibrating platforms 4 , the winch 6 is connected with the counterweight vibrating platform 4 through the lifting rope 2, and the counterweight vibrating platform 4 is provided with a plurality of vibrating motors 3, and the vibrating motors 3 are connected with the vibrating rod 5, and the two adjacent counterweights vibrate The pounding platform 4 is connected by a connecting rod 15, and one side of the counterweight vibrating platform 4 is also provided with a stabilizing device 11. Design the counterweight vibrating platform 4, place two vibrating motors 3 on the counterweight vibrating platform 4, and set the two vibrating rods 5 at the bottom of the vibrating platform acco...

Embodiment 2

[0049] Further illustrate in conjunction with embodiment 1, as Figure 1-4 As shown in the structure, the stabilizing device 11 and the formwork frame 12 have been constructed according to the drawings.

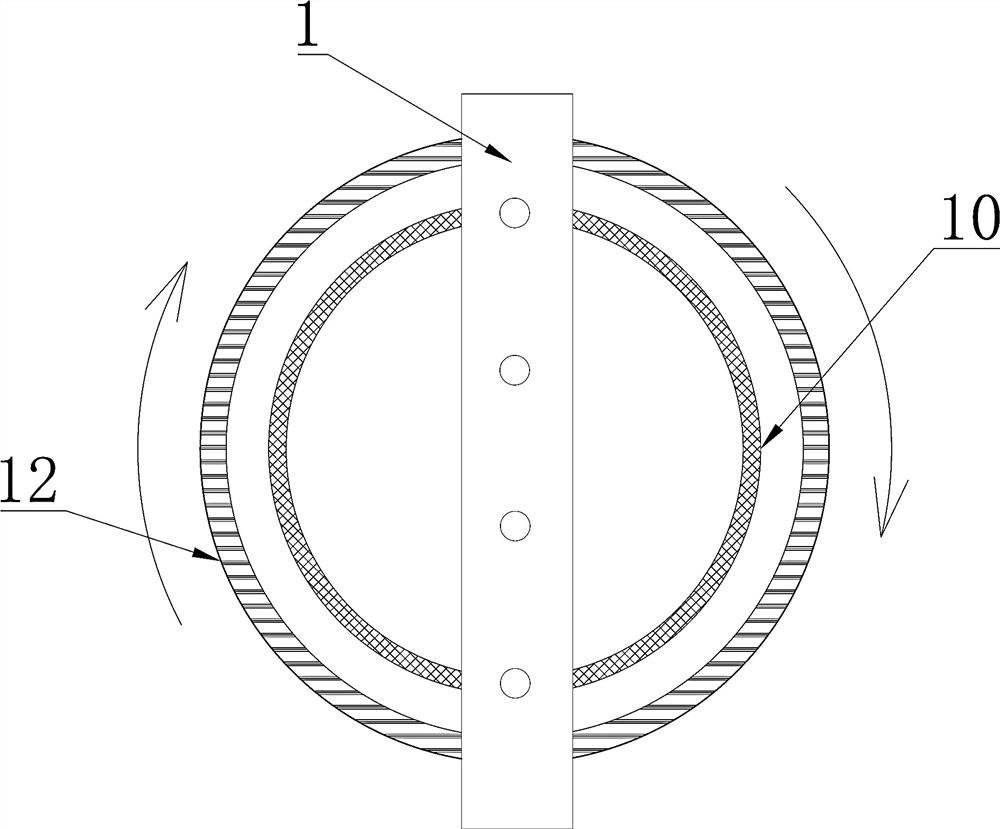

[0050] The crossbeam 1 is hoisted at the opening position of the formwork frame 12 , and the entire counterweight vibrating platform 4 is placed inside the steel cage 10 , and the adjacent counterweight vibrating platforms 4 are connected by connecting rods 15 .

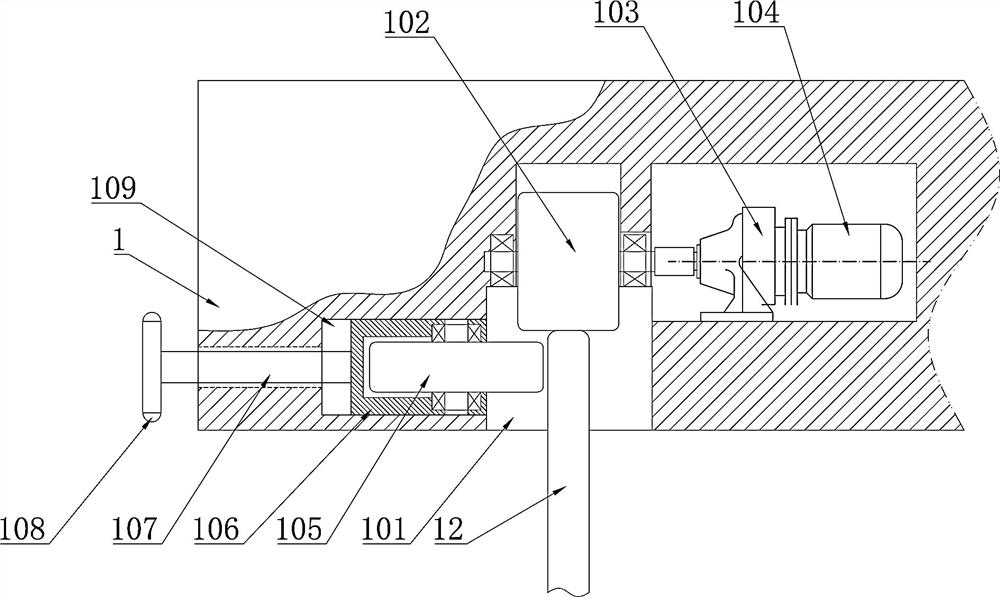

[0051] Place the rollers 102 inside the groove body 101 of the beam 1 on the formwork frame 12 .

[0052] Adjust the crossbeam 1, and adjust the adjustment rollers 105 at both ends of the crossbeam 1 against the outer surface of the formwork frame 12 so that the middle part of the crossbeam 1 is coaxial with the formwork frame 12.

[0053] By rotating the adjusting handle 108 , the adjusting roller 105 abuts against the outer surface of the formwork frame 12 .

[0054] The hoist 6 is controlled to rotate to lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com