Cotton discharging device of cotton opener

A technology of opening machine and cotton, which is applied in the direction of fiber opening and cleaning machines, etc., which can solve the problems of uneven laying of raw materials and slow speed, and achieve the effects of reducing workload, convenient use, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

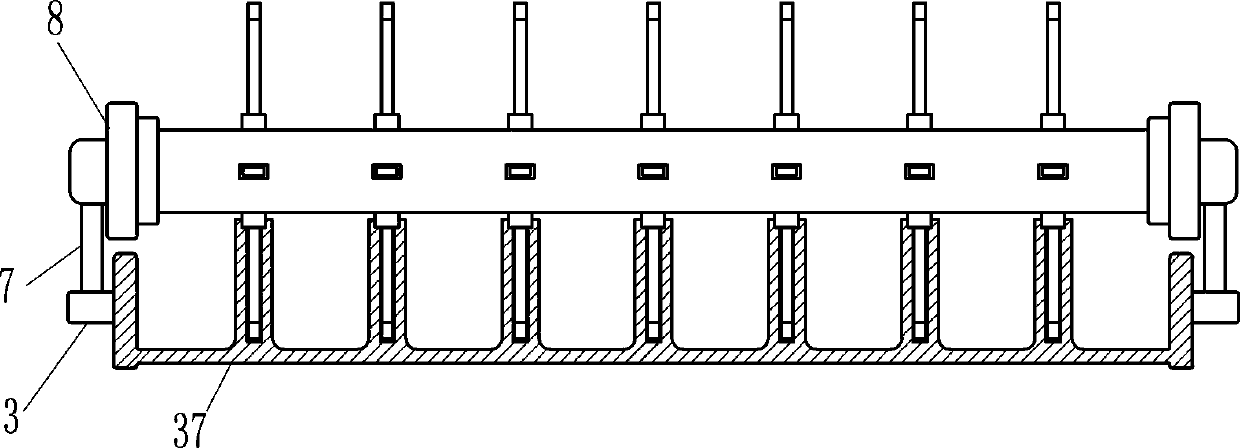

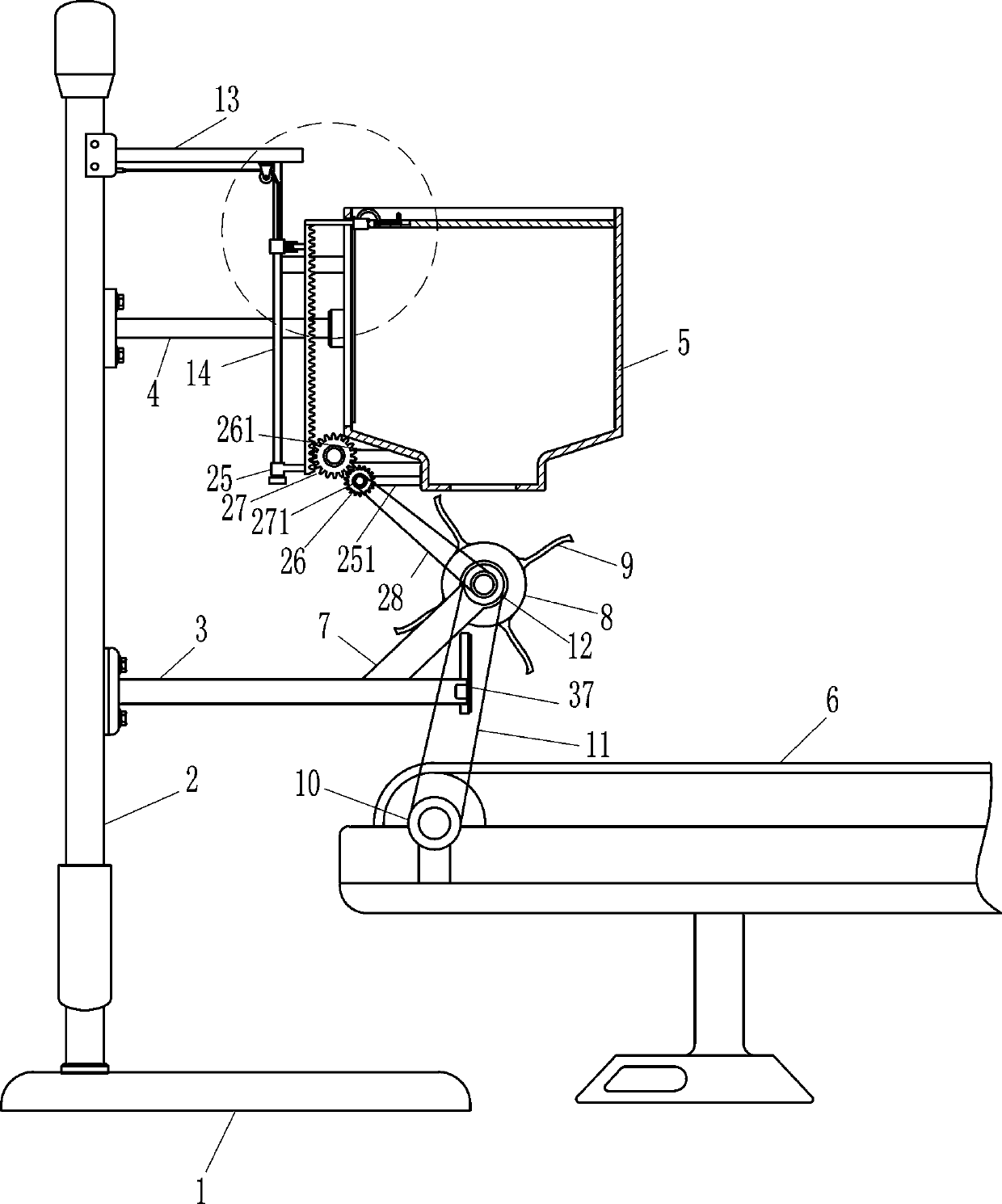

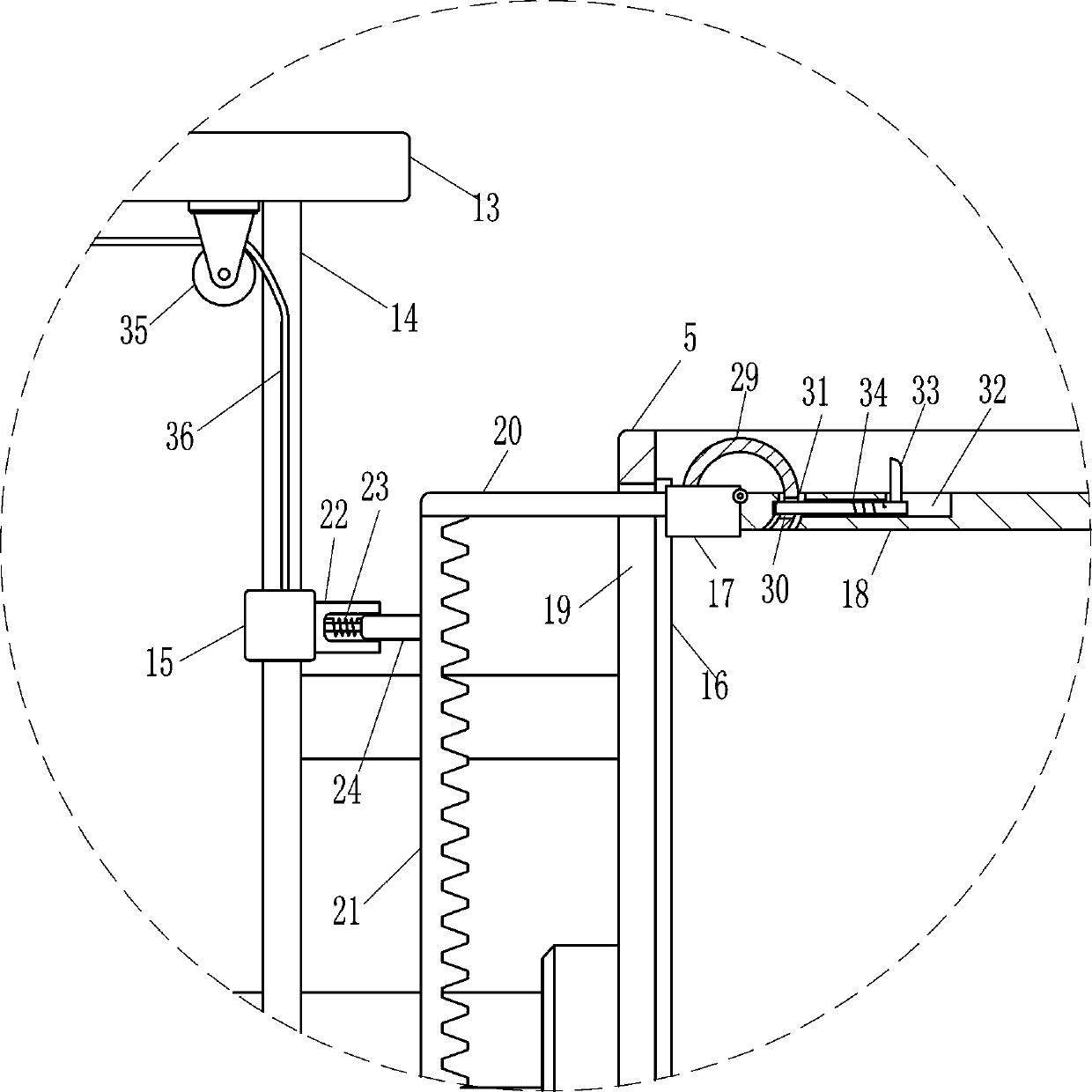

[0019] see figure 1 , figure 2 and image 3 , a kind of cotton unloading device of cotton opening machine, comprises bottom plate 1, mounting plate 2, first pole 3, second pole 4, cotton storage frame 5, shredding device, pressing down device, transmission device and clamping device, the top of the base plate 1 is provided with a mounting plate 2, the lower part of the right side of the mounting plate 2 is provided with a first support rod 3 at the front and rear, the upper part of the right side of the mounting plate 2 is provided with a second support rod 4, and the right end of the second support rod 4 is provided with a There is a cotton storage frame 5, and the right part of the first support rod 3 is provided with a shredding device that shreds the raw material into small pieces by rotating. The pressing device for pressing down is provided with a transmission device between the shredding device and the pressing device, and the cotton storage frame 5 is provided with ...

Embodiment 2

[0025] see figure 1 and image 3 , on the basis of Embodiment 1, in order to use the device better, it also includes a pulley 35 and an elastic cord 36. The bottom of the third pole 13 is provided with a pulley 35, and the left part of the mounting plate 2 is provided with an elastic cord 36. The rope 36 goes around the pulley 35 and is connected with the top of the sliding sleeve 15 . Specifically, the transmission drives the rack 21 to move downward, the rack 21 moves downward to drive the sliding sleeve 15 to move downward, the sliding sleeve 15 moves downward so that the elastic cord 36 is stretched, and the rack 21 is pushed to move to the left. When no longer meshing with the gear wheel 27, the elastic rope 36 resets and drives the sliding sleeve 15 to move upwards to reset, and the sliding sleeve 15 moves upwards to drive the rack 21 to move upwards to reset through the connecting rod 20 and the mounting block 22, so that the rack is pushed without manpower 21 has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com