Slag removal mechanism for water tank

A sink and slag knife technology, which is applied to the washing machine/washing machine for tableware, the parts and application of the washing machine/rinsing washing machine for tableware, etc. problems such as poor effect, to avoid clogging and reduce residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

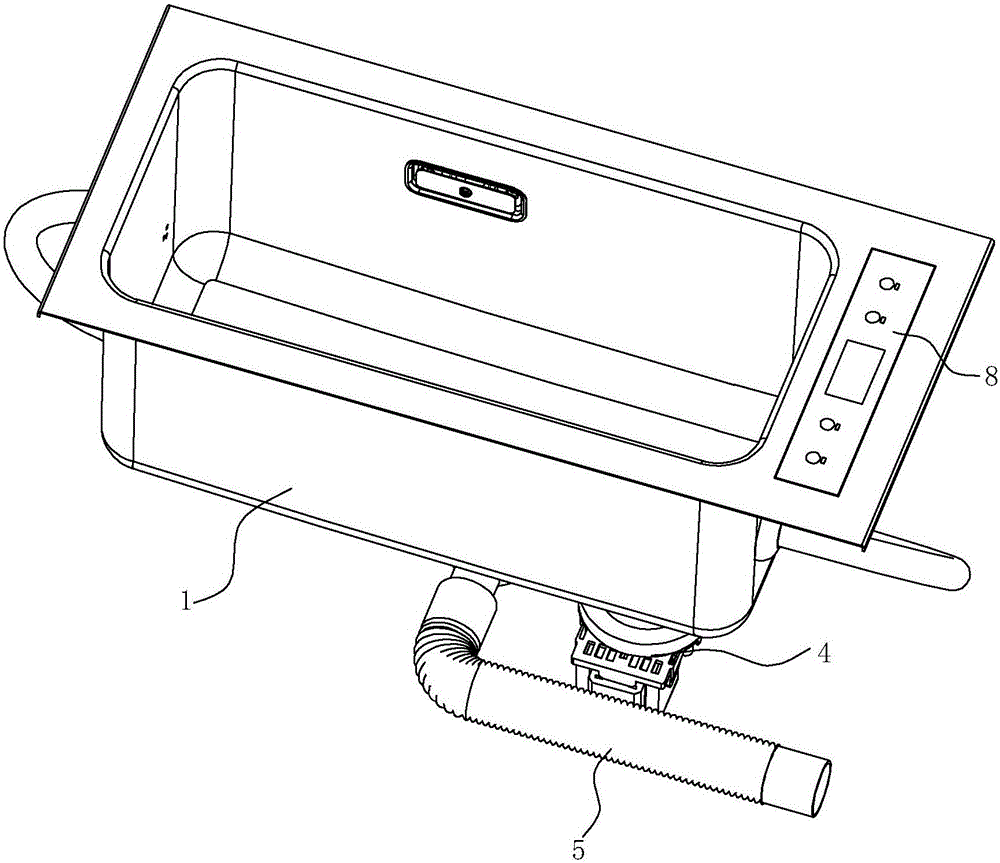

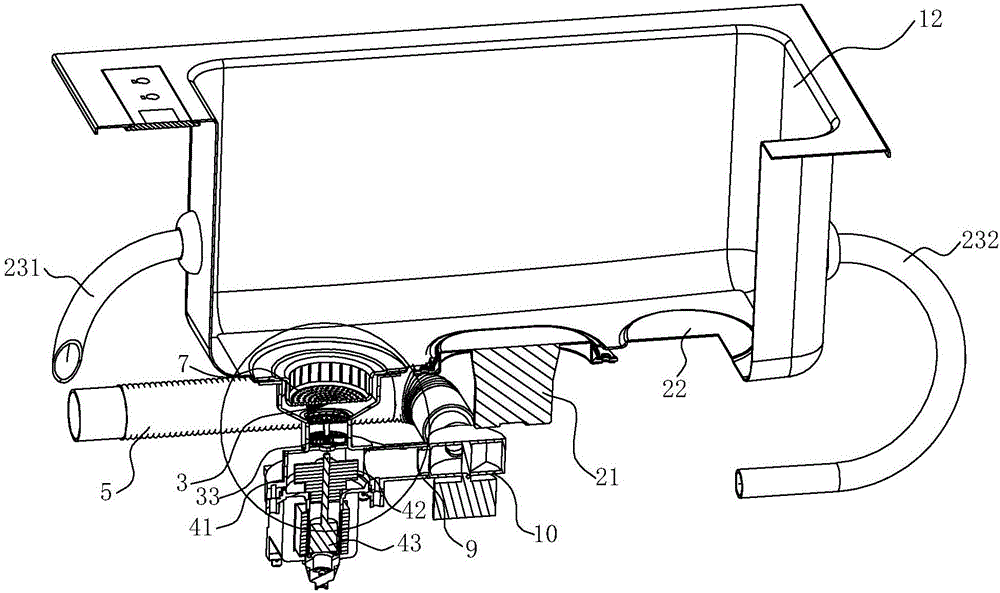

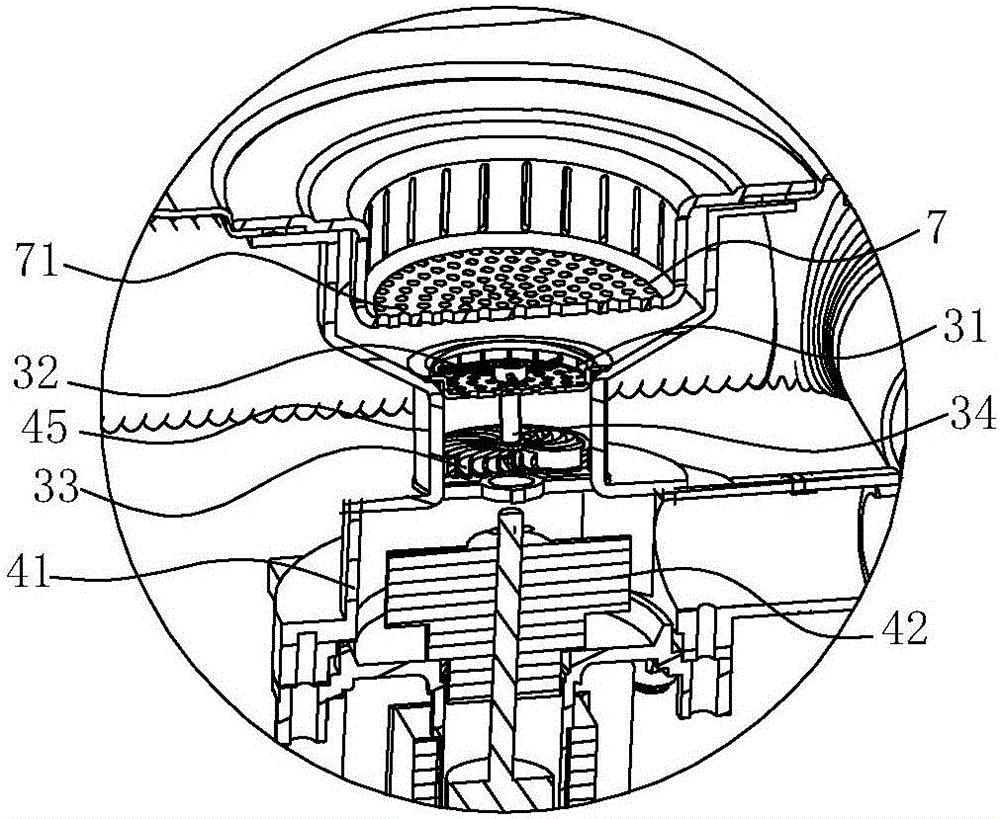

[0025] see figure 1 , figure 2 , a tank cleaning machine, comprising a tank body 1, a cleaning mechanism and a slag discharge mechanism, the slag discharge mechanism comprising a slag twisting mechanism 3, a drainage pump 4, a drain pipe 5, and an upper slag basket 7 arranged at the bottom of the tank body 1, The upper slag basket 7 communicates with the drain pump 4 for filtering the water in the tank body 1 and discharging it. The sink body 1 is provided with a control panel 8 for controlling the cleaning mechanism 2 and the drain pump 4 .

[0026] In this embodiment, the tank body 1 is long and narrow, and the cleaning mechanism includes an ultrasonic generator 21, a heater 22 and a pipeline structure for forming turbulent flow. In order to obtain a better ultrasonic cleaning effect, the ultrasonic generator 21 is arranged on The middle position of the bottom of the water tank body 1 can evenly generate ultrasonic effects on the water tank body 1; Preferable ones may be...

Embodiment 2

[0031] see Figure 5 ~ Figure 8 , in this embodiment, the difference from the first embodiment above is that the slag cutting mechanism 3 also includes a second slag cutting knife 35, a second hydraulic impeller 36 and a second rotating shaft 37, and the second slag cutting knife 35 is located at the first above the slag cutter 32, and the second hydraulic impeller 36 is located below the first hydraulic impeller 33, the second rotating shaft 37 penetrates from the bottom of the first rotating shaft 34 and passes out from the top of the first rotating shaft 34, and the second hydraulic impeller 36 It is arranged at the lower end of the second rotating shaft 37 , and the second slag cutter 35 is arranged at the upper end of the second rotating shaft 37 , so that the second rotating shaft 37 connects the second slag cutter 35 and the second hydraulic impeller 36 . Through the above connection method, the first hydrodynamic impeller 33 and the second hydrodynamic impeller 34 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com