Double-shaft shredding machine

A double-shaft shredder and rack technology, applied in grain processing, etc., can solve problems such as inconvenient maintenance and replacement, machine jamming, blade wear, etc., and achieve the effects of convenient replacement, reduced size, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0030] The drive motor 3 (model is 130ST-M15025) and speed reducer 11 (model is ZQ750) mentioned in the present invention can be purchased from the market or obtained by private customization.

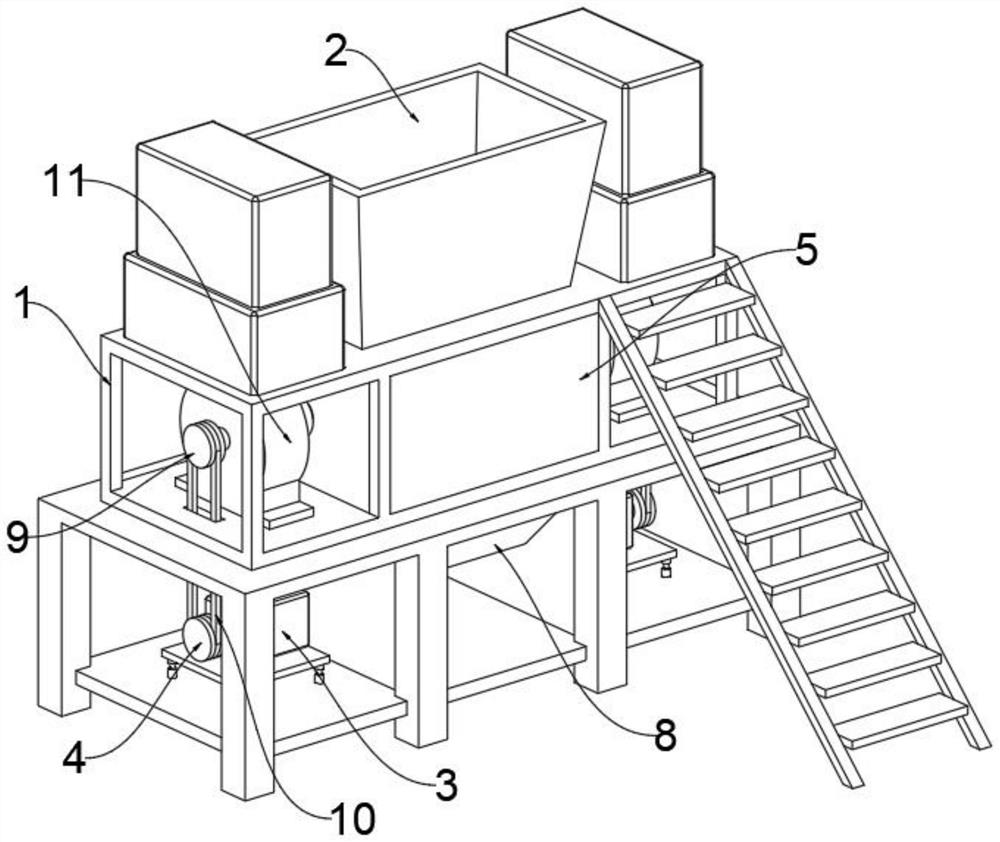

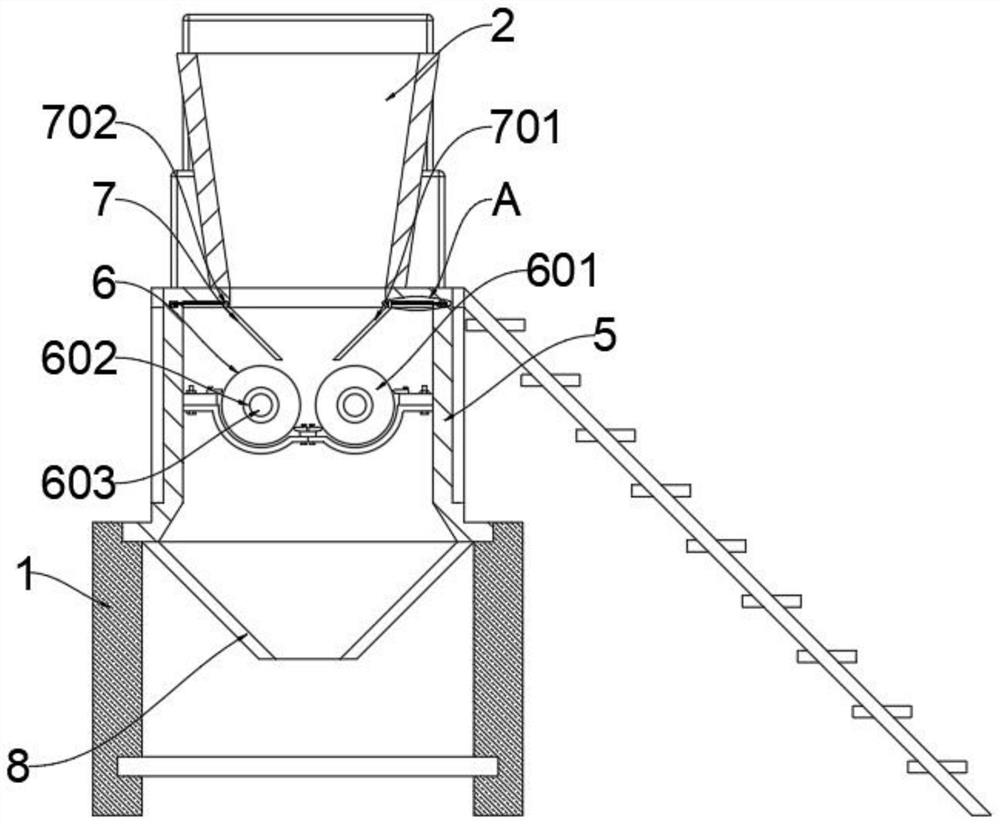

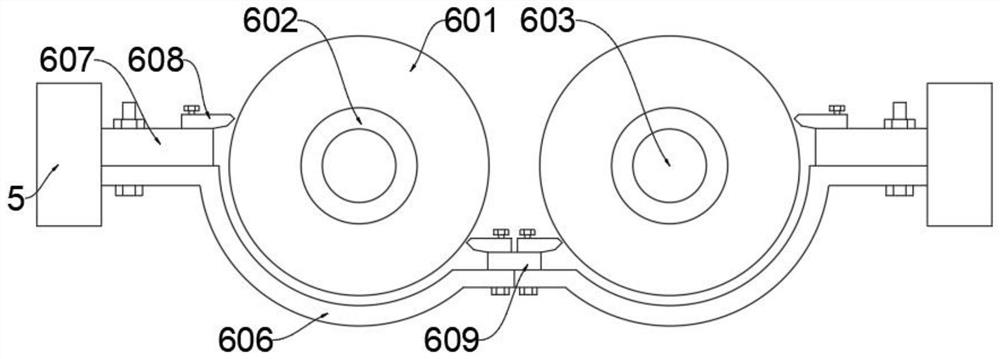

[0031] see Figure 1 to Figure 6 , an embodiment provided by the present invention: a double-shaft shredder, comprising a frame 1, a feed funnel 2 is arranged on the surface of the frame 1, and a shredding box 5 is arranged below the feed funnel 2, and the shredding Box 5 is located in the middle of frame 1, and the bottom of shredding box 5 is provided with discharge funnel 8, and both sides of discharge funnel 8 are all provided with drive motor 3, and the end of drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com