Patents

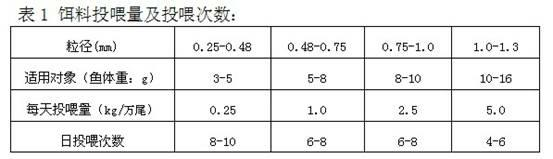

Literature

70results about How to "Settling speed is slow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

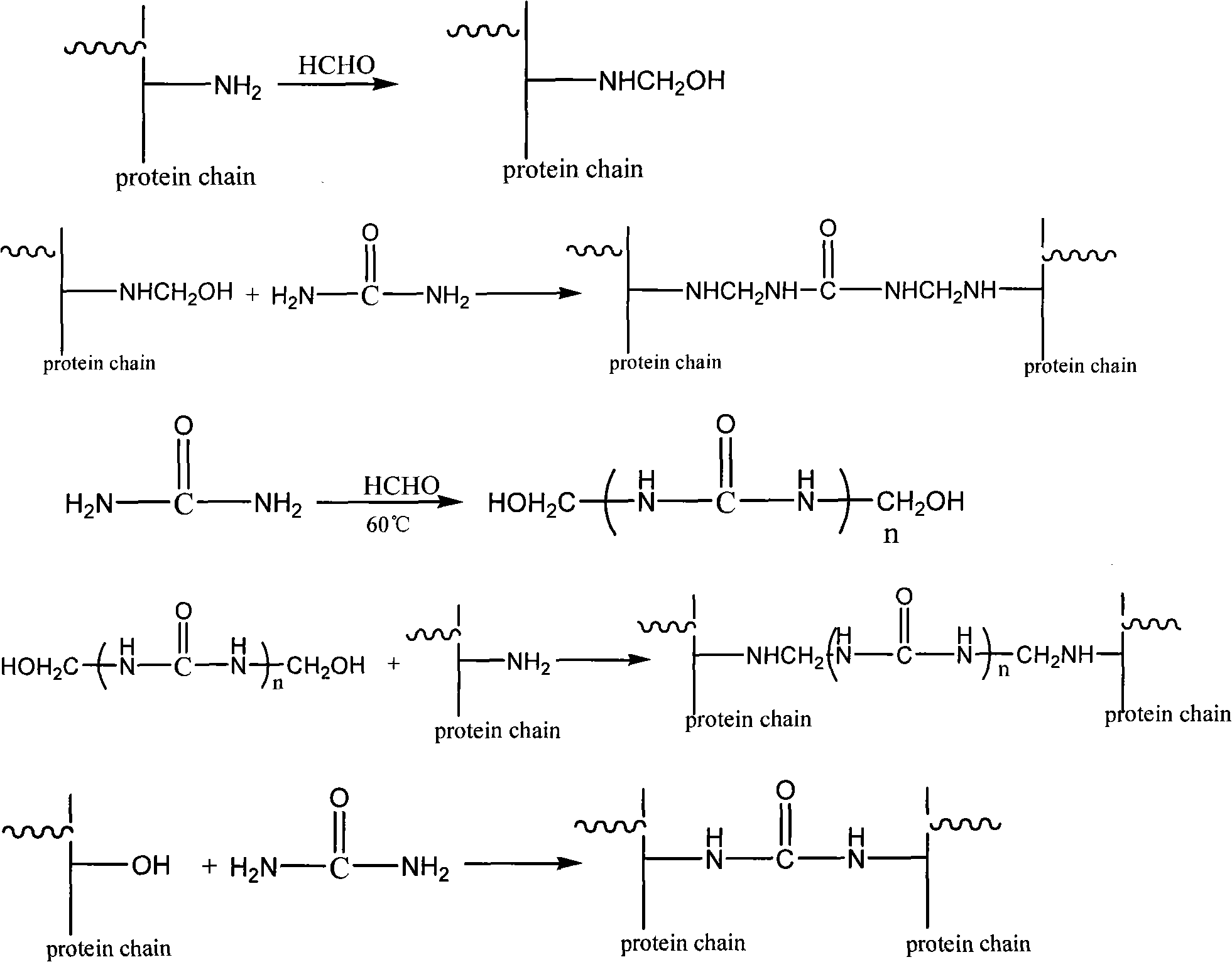

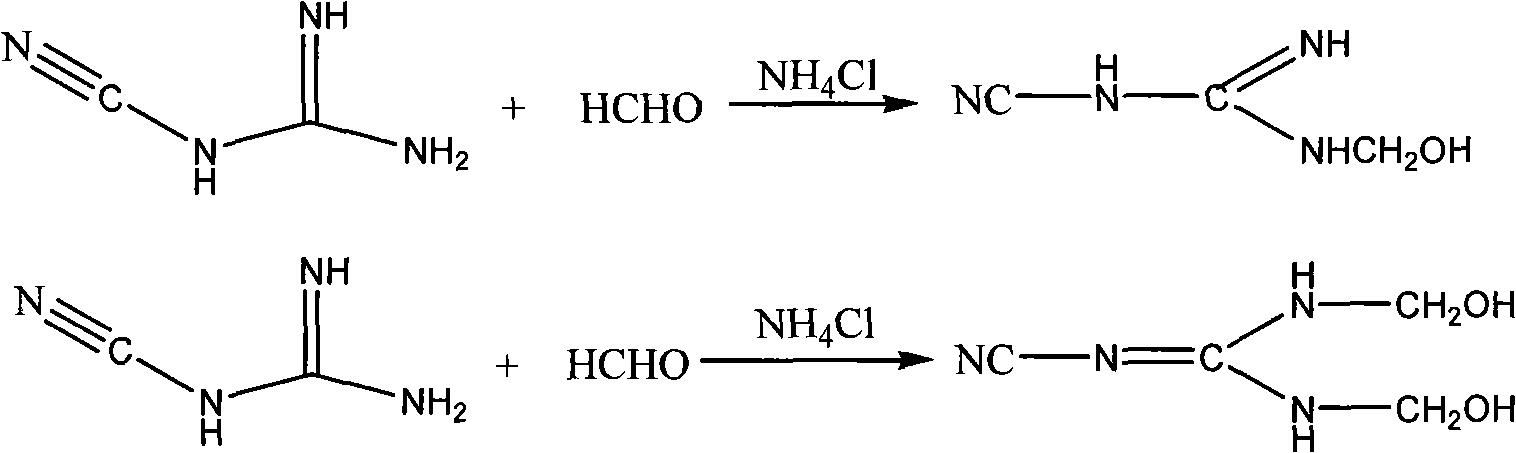

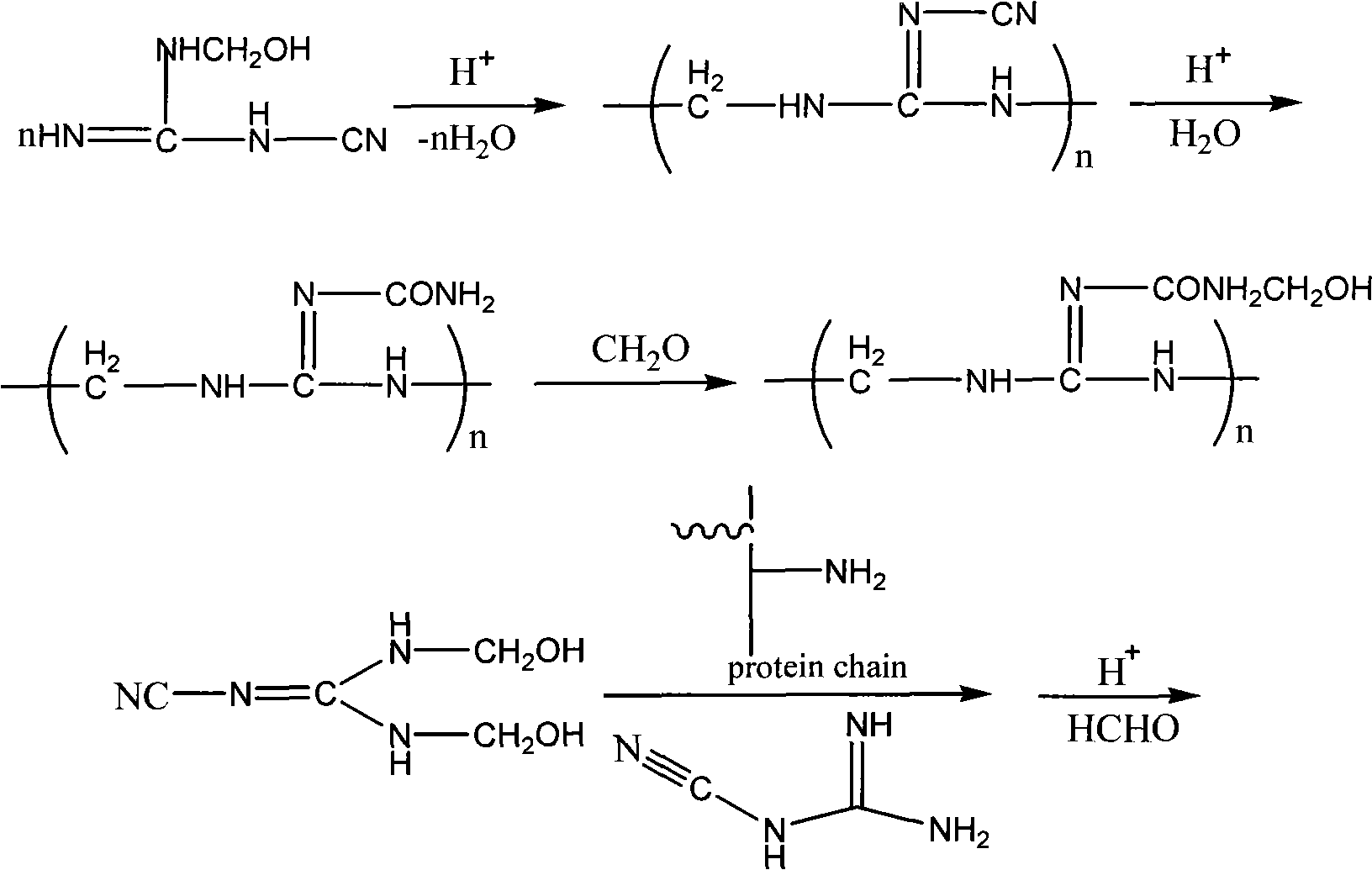

Protein flocculant for treating printing and dyeing wastewater

InactiveCN102115239AHigh decolorization rateReduce dosageWater/sewage treatment by flocculation/precipitationWater dischargeProtein molecules

The invention discloses a protein flocculant for treating printing and dyeing wastewater. The protein flocculant for treating the printing and dyeing wastewater is prepared from various animal protein powders originating from cheap waste animal pelts, hoofs, animal fur powders and bean pulps aiming at different groups in a protein molecule and a chemical modifier for reaction. The invention simultaneously provides a protein flocculant compound. The invention provides a simple and practicable method; and by utilizing the method, various dye waste waters discharged in printing and dyeing plants and dye production plants can be effectively treated, and the product cost is cheap.

Owner:中国中化股份有限公司 +1

An environment friendly expanded mixed feedstuff for rockfishes and method for preparing same

ActiveCN1864523APromotes rapid dust growthImprove digestion and absorption rateFood processingClimate change adaptationVegetable oilFish paste

The present invention is one kind of green compounded and puffed feed for rock fish. The green compounded and puffed feed is prepared with steamed fish meal 35-50%, soybean residue 15-20%, pork bone powder 5-12%, beer yeast 3-5%, cuttle fish paste 2-6%, fish oil 1.0-2%, vegetable oil 1-2%, macaroni flour 10-20%, shrimp shell powder 3-6%, lecithin 1-2%, vitamins 0.3-0.5%, compounded mineral 0.5-1% and choline chloride 0.3-0.5%, and through mixing, crushing, extruding to pelletize, and stoving. The green compounded and puffed feed has simple compounding process and balanced nutrients, can meet the requirement of the growth of rock fish, and results in less water contamination.

Owner:GUANGDONG EVERGREEN FEED INDAL

Micro particle feed for rockfish fry and its production procss

InactiveCN1442078ASolve the bottleneck of severe shortage of supplyHigh economic valueClimate change adaptationAnimal feeding stuffRockfishAntioxidant

A microgranular bait for the fry of Epinephelus is prepared from crude protein, crude fat, phosphatide, ash, n-3HUFA, DHA / EPA, DHA, and EPA according to a certain proportion through enzymolyzing by proteinase, further adding antioxidizing agent, filtering, and spray drying. Its advantages are rich nutrients, and low settling speed.

Owner:SUN YAT SEN UNIV

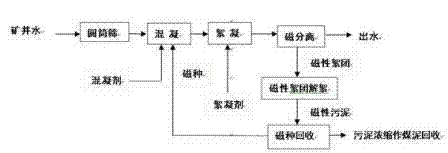

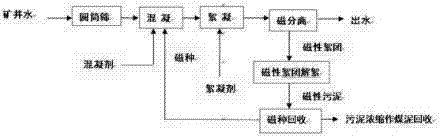

Treatment process for mine water of coal deep well

InactiveCN102515325ASolve unresolved technical problemsGuaranteed uptimeWater/sewage treatment by flocculation/precipitationSludgeSewage treatment

The invention belongs to the field of sewage treatment, and particularly relates to a treatment process for the mine water of a coal deep well. The process comprises the following working procedures of: removing impurities; magnetizing to coagulate; flocculating; magnetically separating; deflocculating magnetic floccules; and recovering magnetic seeds, wherein the deflocculating magnetic floccules means adding water in the magnetic floccules separated out in the working procedure of magnetically separating to stir with a high speed, and dispersing out sludge and magnetic seeds in the magnetic floccules; and the recovering magnetic seeds means recovering magnetic seeds from the sludge after the magnetic floccules are deflocculated. The treatment process disclosed by the invention is reliable in operation and high in the recovery rate of magnetic powder in treatment for the mine water of coal deep well, and solves the technical problems unsolved in the technical field of water treatment for the mine water of coal deep well.

Owner:SCIMEE TECH & SCI CO LTD

Micro particle feed for cultivating juvenile sea cucumber and preparation method thereof

InactiveCN101715900AMeet growth needsLow dissolutionClimate change adaptationAnimal feeding stuffYeastSargassum thunbergii

The invention discloses a micro particle feed for cultivating juvenile sea cucumber and a preparation method thereof, wherein the micro particle feed for cultivating juvenile sea cucumber can completely meet the needs for various nutrients of the juvenile sea cucumber for growth and solves a biological bait shortage problem during artificial sea cucumber breeding. The micro particle feed comprises the following components in percentage by weight: 15 to 20 percent of fish meal, 5 to 10 percent of bean pulp, 20 to 50 percent of sargassum thunbergii powder, 10 to 15 percent of sea mud, 5 to 20 percent of marine algae powder, 5 to 10 percent of yeast and 0.5 to 1 percent of vitamin premix. The preparation method comprises: mixing the fish meal, the beam pulp, the sargassum thunbergii powder, the sea mud, the marine algae powder, the yeast and the vitamin premix; coating a film with carboxymethylcellulose and wheat gluten, wherein the mass ratio of the carboxymethylcellulose to the wheat gluten is 1:1-3; and drying the mixture under vacuum and crushing the mixture into particles with a particle size ranging from 100 to 500mum.

Owner:DALIAN FISHERIES UNIVERSITY

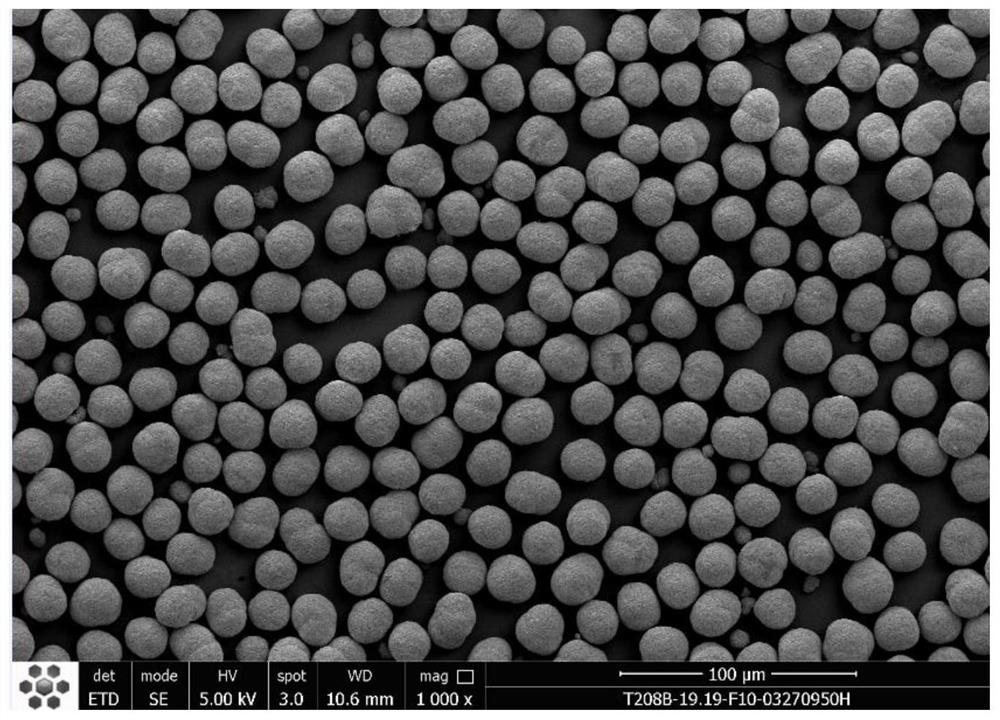

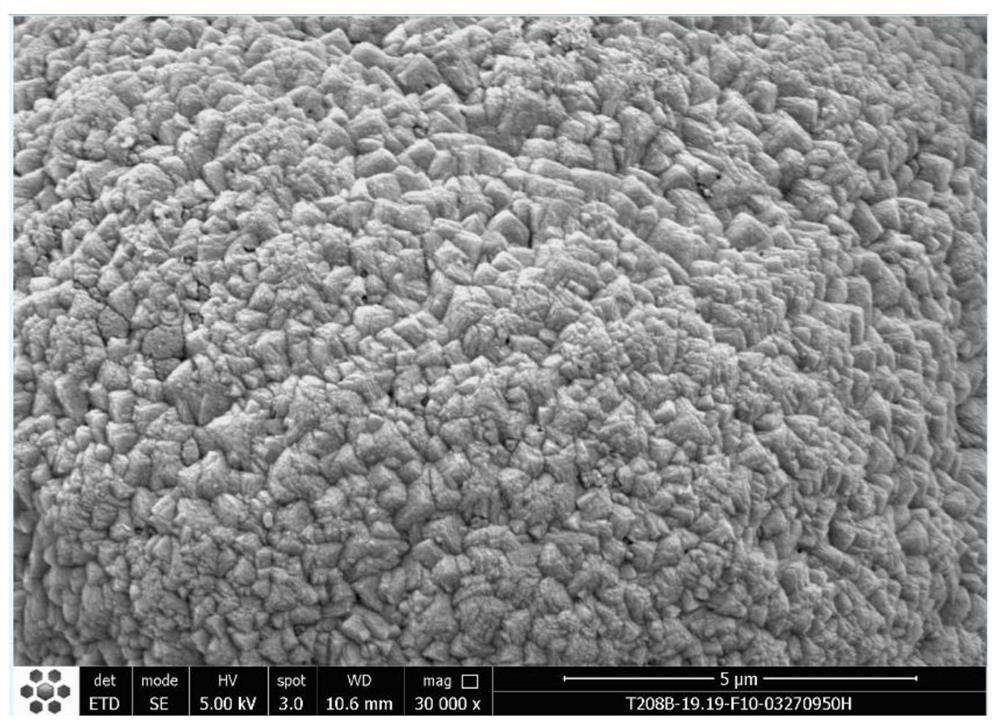

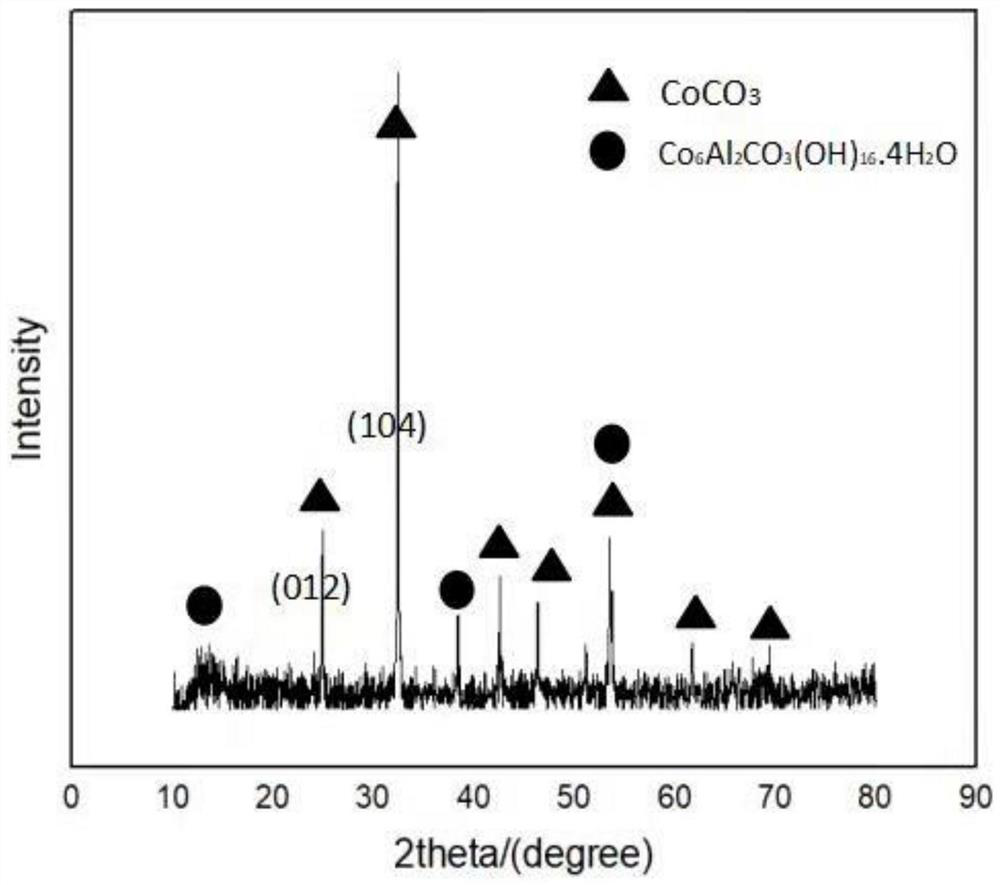

Doped large-particle cobalt carbonate and preparation method thereof

ActiveCN113307308AHigh tap densityNarrow particle size distributionCobalt carbonatesCrystallinityCobalt

The invention relates to doped large-particle cobalt carbonate and a preparation method thereof. The large-particle cobalt carbonate is doped with metal elements, primary particles are conical in morphology and form spherical secondary particles, and the particle size distribution range of the secondary particles is that (D90-D10) / D50 is larger than or equal to 0.3 and smaller than or equal to 0.5; and the preparation method comprises the following steps: nucleation, concentration, growth in a seed crystal kettle, and growth of the seed crystal in different kettles. The doped large-particle cobalt carbonate is high in crystallinity, beneficial to uniform distribution of doped element aluminum, high in tap density, narrow in particle size distribution and beneficial to reduction of aluminum segregation of small particles; and according to the preparation method, the D50 rising speed and the solid content rising speed are strictly controlled, uniform growth of cobalt carbonate particles is guaranteed by adjusting the flow and the rotating speed in different solid content intervals, the concentration process greatly saves the standing waiting time, the efficiency is high, and the obtained product is good in performance and has a wide market prospect.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

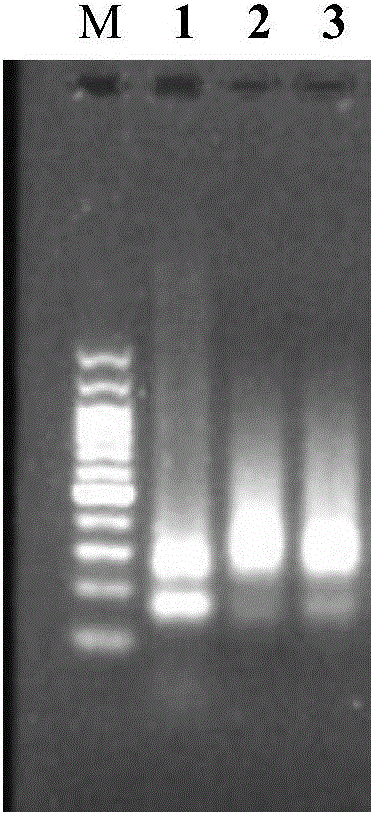

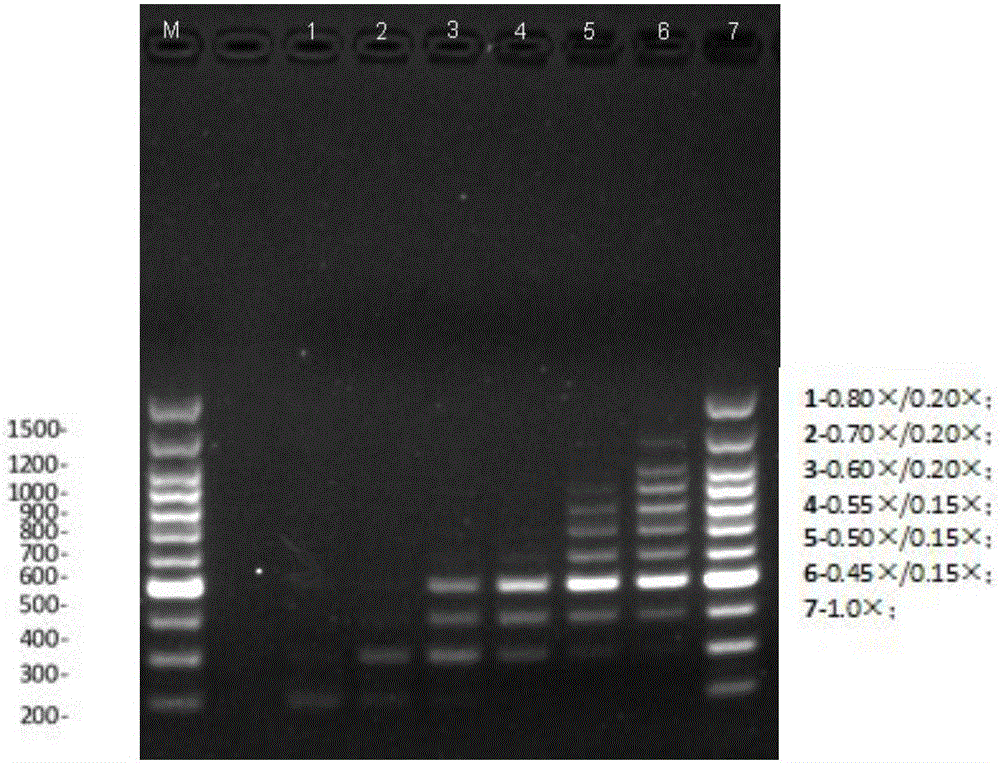

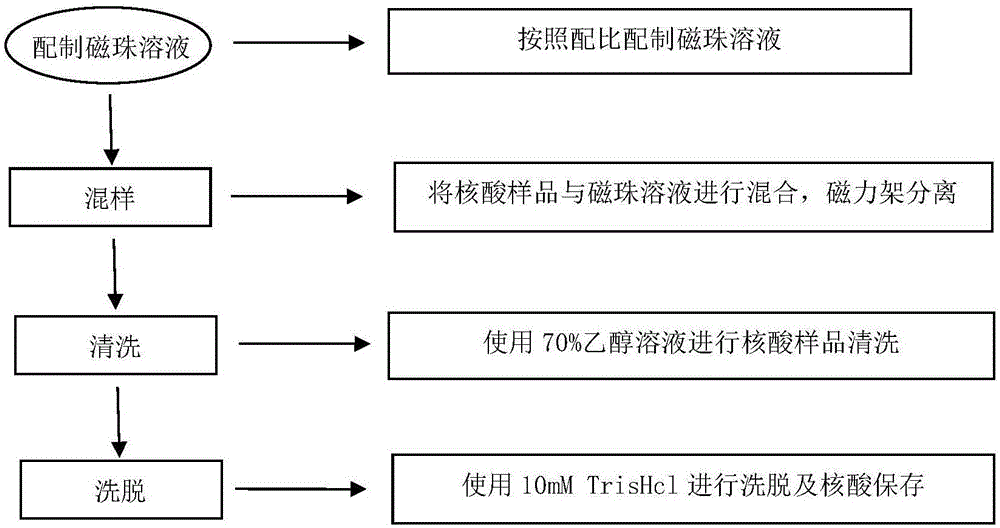

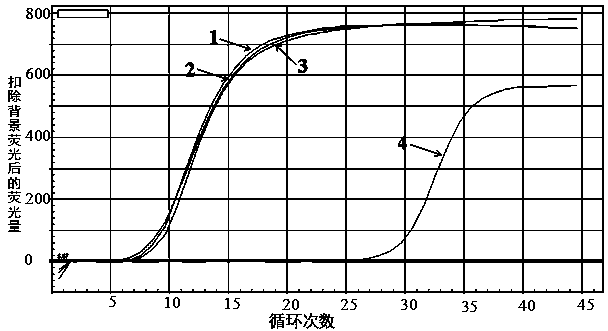

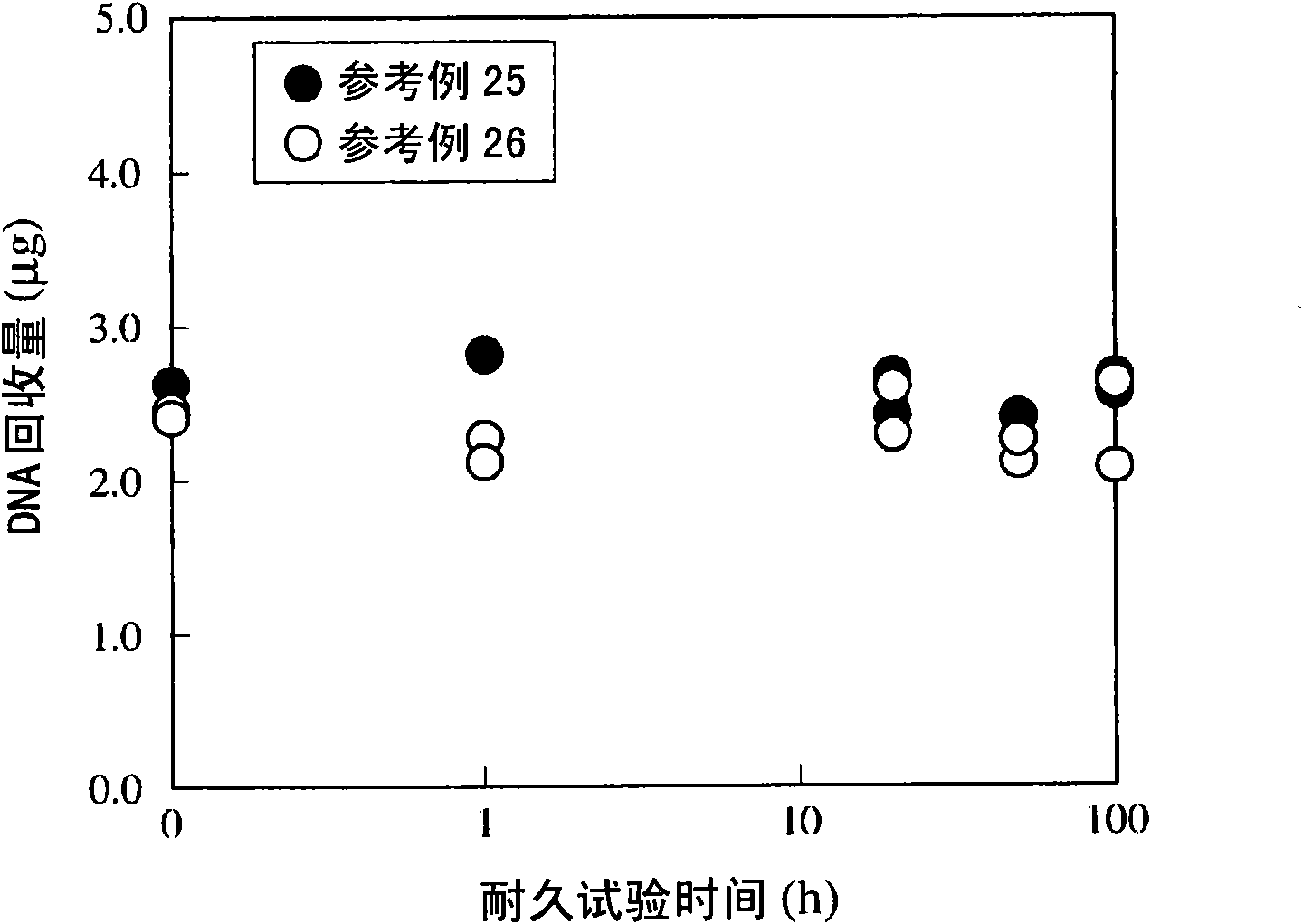

Magnetic bead composition for improving nucleic acid extraction rate and application of magnetic bead composition

The invention belongs to the field of molecular biology technologies, and particularly relates to a magnetic bead composition for improving a nucleic acid extraction rate and an application of the magnetic bead composition. The magnetic bead composition comprises the following components by concentration: nano magnetic beads of 1mg / mL, polyethylene glycol 8000 of 0.018-0.026mol / L, sodium chloride of 2.2-2.6mol / L, an ethylenediamine tetraacetic acid solution of 0.5-2mol / L, and a trihydroxymethyl aminomethane solution of 10-20mmol / L. The magnetic bead solution provided by the invention can strengthen the adsorption efficiency of the magnetic beads and nucleic acid and can greatly improve the extraction rate; and especially for extraction of a trace-amount nucleic acid sample, the magnetic bead solution is more obvious in advantage, and reduces the operation time.

Owner:广州奇辉生物科技有限公司

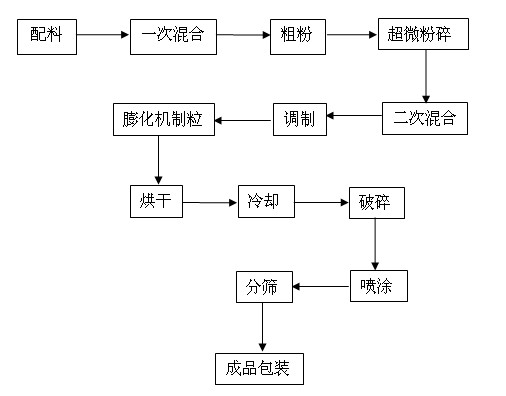

Microparticle feed for sturgeon fry and processing method of same

InactiveCN102578428AIncrease profitImprove digestion and absorption rateAnimal feeding stuffBetaineFish oil

The invention relates to a microparticle feed for sturgeon fry and a processing method of same. The microparticle feed for the sturgeon fry comprises the following components by weight percet: 50-60 percent of fish meal, 10-15 percent of hydrolyzed fish protein, 10-15 percent of yeast powder, 5-10 percent of wheat flour, 3-5 percent of amylose, 5-6 percent of fish oil, 0.1-0.2 percent of choline chloride, 0.1-0.7 percent of lysine, 0.1-0.6 percent of methionine, 1-2 percent of betaine, 0.1-0 .3 percent of protease, 0.2-0.4 percent of lipases and 1-3 percent of compound vitamin and 1-3 percentof compound mineral substance. The processing method of the microparticle feed comprises the following steps: 1), weighing the components; 2), mixing the weighed raw materials primarily; 3), performing ultrafine grinding; 4), mixing the weighed raw materials primarily secondarily and stirring; 5), heating and curing by using a processing device; 6), extruding and granulating; 7), drying; 8), cooling by using a cooler; 9), crushing by using a roller-type crusher; 10), spraying; 11), screening; and 12), packaging. The microparticle feed for the sturgeon fry has the advantages of comprehensive nutrition, good phagostimulant performance, low settling speed, stability of the microparticle feed for the sturgeon fry in water as long as 24 hours without collapsibility, and the like.

Owner:AQUATIC PROD RES INST SHANDONG PROV

Rare earth fluorescent powder and preparation method thereof

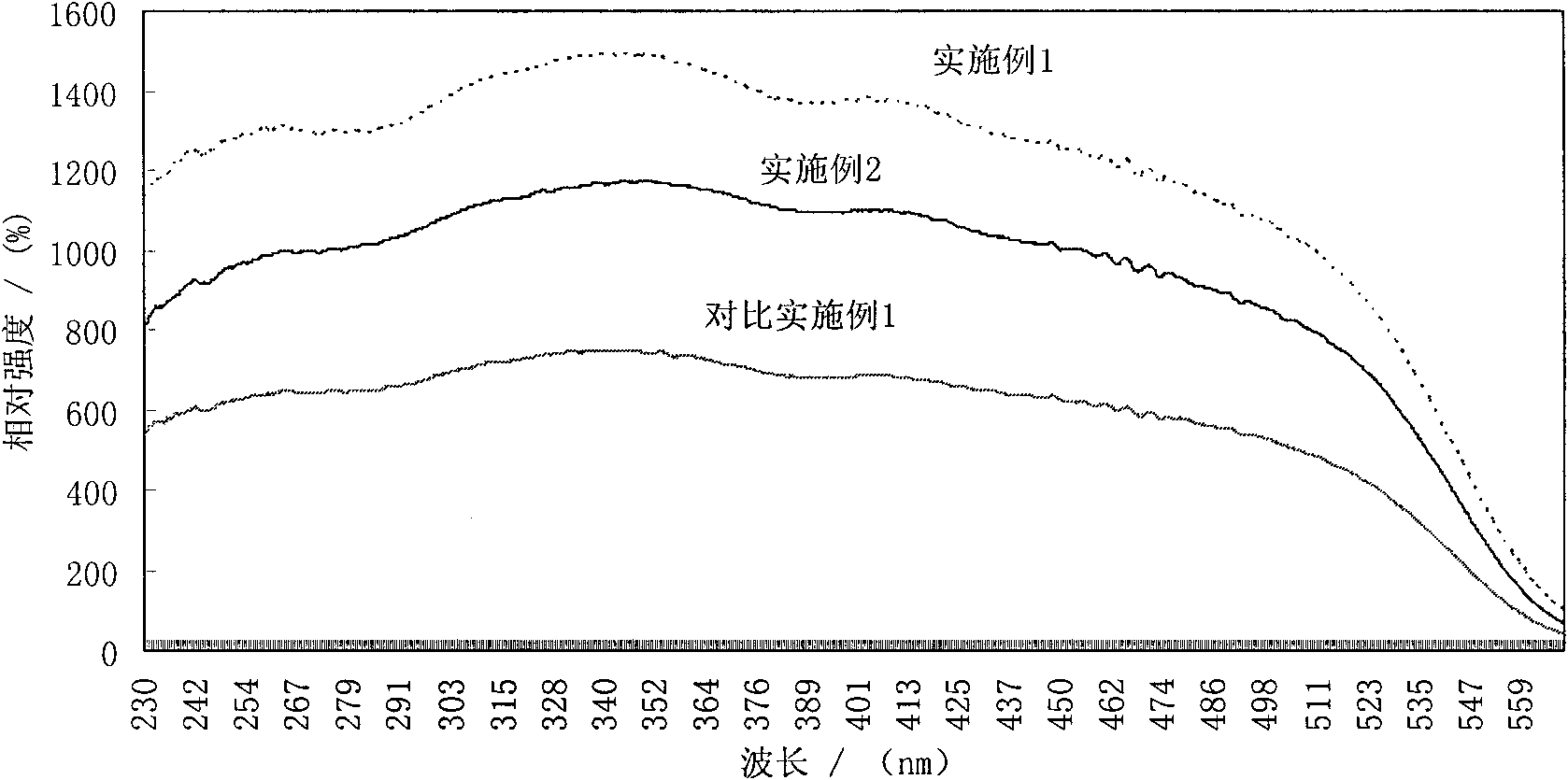

ActiveCN101838535AReduce crystal field strengthImprove the anti-light decay characteristicsGas discharge lamp usageLuminescent compositionsMetallurgyRare earth

The invention provides rare earth fluorescent powder and a preparation method thereof. The chemical structural formula of the rare earth fluorescent powder is Sr(3-x-y-z)BaxMepSiqO(3+2q+p / 2):Euy, Rz, wherein Me is at least one of Li, Na and K; R is at least one of La, Gd and Lu; x is more than or equal to 0.001 and less than or equal to 0.2; y is more than or equal to 0.001 and less than 0.12; z is more than or equal to 0.0001 and less than 0.08; p is more than or equal to 0.001 and less than 0.05; q is more than or equal to 0.65 and less than 1. The method can effectively control the grain diameter of the calcined product; and the prepared fluorescent powder has the advantages of small grain diameter, narrow distribution, high lighting effect, capability of effectively enhancing the lighting effect and light color consistency of a white LED, and high luminous performance, chemical stability and temperature quenching characteristic.

Owner:JIANGSU BREE OPTRONICS CO LTD

Preparation method of olefin polymerization catalyst slurry

The invention relates to a preparation method of olefin polymerization catalyst slurry. The preparation method of the olefin polymerization catalyst slurry is characterized in that in olefin polymerization catalyst component preparation, after low-boiling point alkane washing, catalyst suspension is formed and then is directly mixed with mineral oil; and the mixture is subjected to vacuum drying with stirring. The olefin polymerization catalyst slurry obtained by the preparation method has a slow sedimentation rate and good stability, and is suitable for continuous production adopting a vaporphase method-based polypropylene production device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fenbendazole dry emulsion and preparation method thereof

InactiveCN105456260ASettling speed is slowImprove physical stabilityPowder deliveryOrganic active ingredientsFenbendazoleSuspending Agents

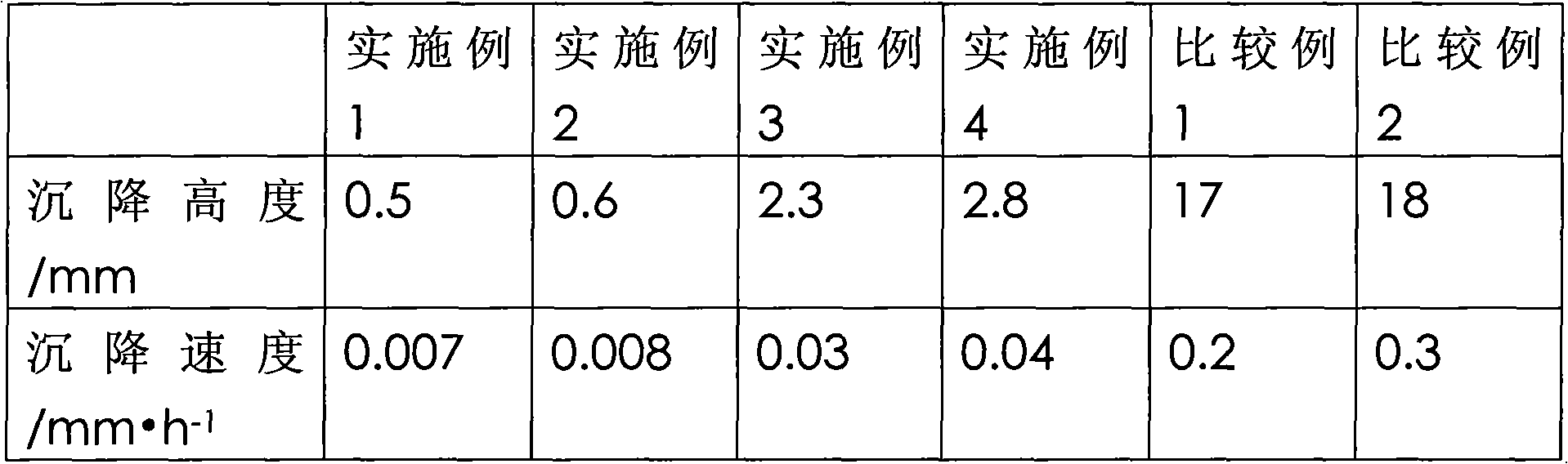

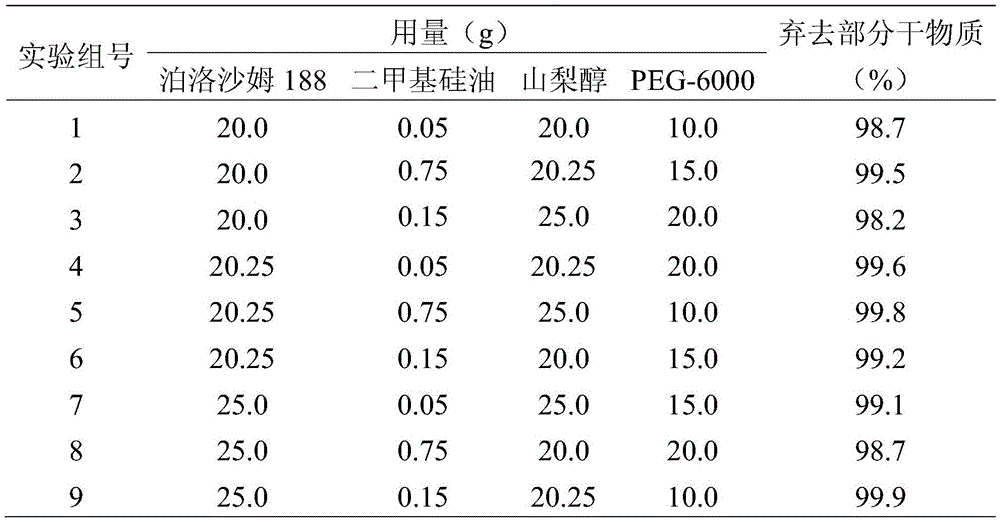

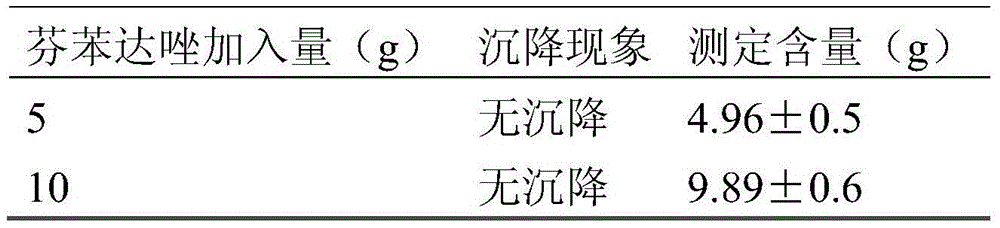

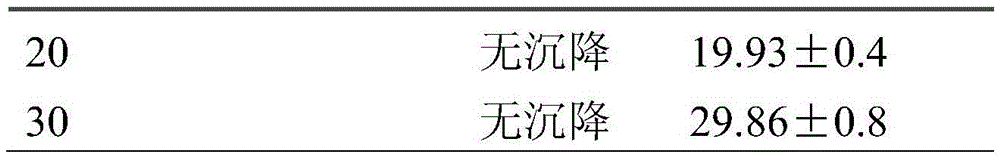

The invention discloses a fenbendazole dry emulsion. The fenbendazole dry emulsion is prepared from, by weight, 5-30 parts of fenbendazole, 20-25 parts of emulgator, 10-25 parts of suspending agent, 20-25 parts of colloid protection agent, 0.05-0.25 part of surface active agent and 0.05-1 part of oil phase. It is indicated through a quality evaluation experiment that the fenbendazole dry emulsion is low in settling velocity, good in physical stability, simple in preparation process, high in bath-to-batch quality stability and convenient to use and carry, the quality requirement of suspensions is met, and good application prospects are achieved.

Owner:CHENGDU QIANKUN VETERINARY PHARMA

Preparation method for fish feed

InactiveCN106578702AAchieve decompositionAchieve maximum utilizationFood processingClimate change adaptationCelluloseFluidized bed

The invention discloses a preparation method for a fish feed. The preparation method comprises the following steps of (1) performing alkaline hydrolysis, namely, mixing peanut shells, wheat straws, soybean curd residues with plant ash, adding water for pulpifying, and stirring for reacting to obtain an alkaline hydrolysis product; (2) fermenting, namely, uniformly mixing corn, mulberry leaves, wheat bran and the alkaline hydrolysis product, adding amylase, protease, polysaccharase and cellulose, then adding yeast, and stirring and mixing uniformly for fermenting; (3) granulating, namely, drying a fermenting material, then, mixing mineral substances, bicarbonate and additives, and granulating in a granulating machine, wherein the particle size of the granulated particles is 0.5 to 1 cm; (4) coating, namely, coating the granulated fish feed particles in a fluidized bed, wherein the coating thickness is 0.05 to 0.1 cm; and (5) performing heat expansion, and placing the coated feed capsule particles for 2 to 4 hours at 40 to 60 DEG C. The preparation method for the fish feed provided by the invention is low in cost and simple in process; the obtained fish feed is low in settling velocity and rich in nutrition; and the pollution to a water body is avoided.

Owner:永登富源农业科技发展有限公司

Preparation method of olefin polymerization catalyst component slurry

The invention relates to a preparation method of olefin polymerization catalyst component slurry; during the preparation process of olefin polymerization catalyst components, a catalyst suspension is mixed with mineral oil, and vacuum drying is performed under an ultrasonic condition; the catalyst slurry obtained by the method has a low sedimentation rate, good stability, and is suitable for continuous production of gas-phase polypropylene devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

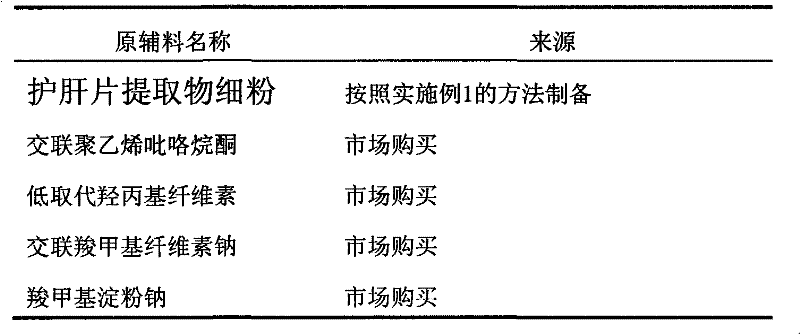

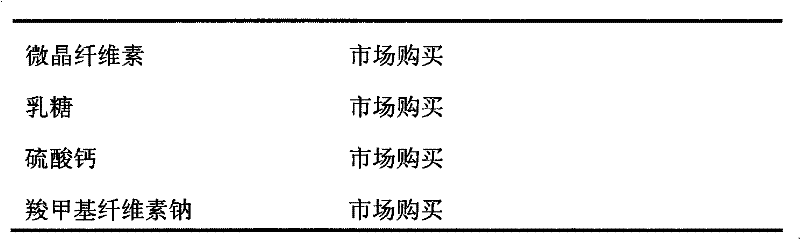

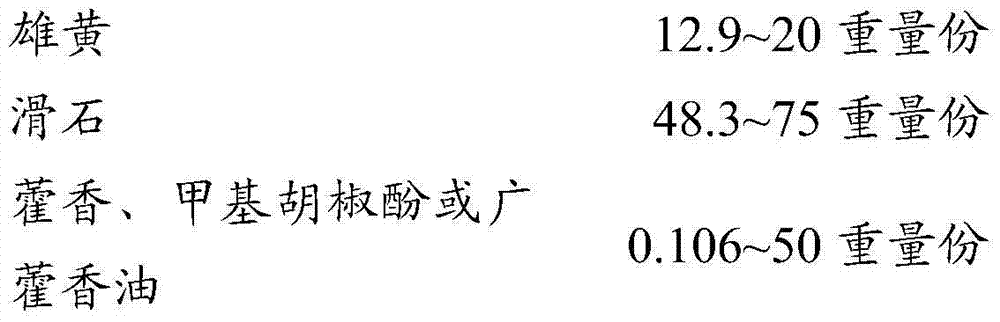

Dispersion tablets of traditional Chinese medicine composition

ActiveCN102218092ASolve the technical problems of the new dosage form of dispersible tabletsEvenly dispersedDigestive systemAntiviralsCarboxymethyl celluloseLow-substituted hydroxypropylcellulose

The invention discloses dispersion tablets of a traditional Chinese medicine composition, Chinese thorowax root, virgate wormwood herb, indigowoad root and mung bean (pulverized) are decocted with water twice with 2 hours for every time, thereby obtaining clear paste A; and Chinese magnoliavine fruit is pulverized into coarse powder, and extraction with 90% ethanol is performed on the coarse powder and porcine gall powder to obtain extract B. The clear paste A and the extract B are uniformly mixed, dried at the temperature of 70 DEG C and pulverized into fine powder, thus obtaining the fine powder of the extract of the traditional Chinese medicine composition; the fine powder is further uniformly mixed with sodium carboxymethyl starch, crosslinked polyethylene pyrrolidone, crosslinked sodium carboxymethyl cellulose, microcrystalline cellulose, low substituted hydroxypropy cellulose, lactose and other auxiliary materials; and granulation is performed through the dry pressing process, 16-mesh size granulation is performed, magnesium stearate is added, and uniform mixing and tabletting are performed, thus obtaining the dispersion tablets.

Owner:BEIJING ASIA EAST BIO PHARMA CO LTD

Modified zeolite powder and raw water processing method thereof

InactiveCN101234328AAmmonia nitrogen concentration is not requiredQuality improvementSilicon compoundsWater/sewage treatment by sorptionSludgeWater quality

The invention relates to a modified zeolite powder and a raw water treatment method thereof, wherein the modified zeolite powder is formed by mixing the natural zeolite powder and modifying agent which comprises one or more substances of powdered activated carbon, diatomite, coal ash and clay; the modified zeolite powder is put into raw water to be treated. The modified zeolite powder and a raw water treatment method has the advantages that the modified zeolite powder is suitable for raw water treatment with different water qualities, can effectively remove pollutants such as ammonia-nitrogen and organic compounds and has certain capability of removing phenolic pollutants and a plurality of pollutants; with higher chemical activity and biological stability, the modified zeolite powder is fast in absorption speed, high in efficiency and has no secondary pollution; through wet type feeding, the modified zeolite powder is low in settling velocity, long in reaction time with the raw water, better in dewatering performance of sludge in sedimentation tanks after the treatment and the post treatment is convenient; the zeolite powder is low in cost, simple in manufacturing method, convenient in use and can reduce the construction difficulty and cost, which is suitable for sudden accidents of water contamination.

Owner:李怀正 +3

Preparation method of ablation-resistant heat insulation paint

InactiveCN104804608AThe preparation method is simple and easySettling speed is slowPretreated surfacesCoatingsAlcoholSpray coating

The invention relates to a preparation method of ablation-resistant heat insulation paint, and belongs to the field of heat insulation paint. The heat insulation paint comprises 29 percent to 34 percent of phenol-formaldehyde resin and 66 percent to 72 percent of 22-1 type powder. The preparation method of the heat insulation paint comprises the following steps that absolute ethyl alcohol, 29 percent to 34 percent of phenol-formaldehyde resin and 66 percent to 72 percent of 22-1 type powder are sequentially added into a reaction vessel; after the stirring is carried out for 50 to 60 minutes, a small amount of large-granule powder which is not uniformly dispersed is filtered by a 200-mesh screen mesh; a heat insulation paint solution is obtained, wherein the adding proportion of the absolute ethyl alcohol is 1.3 to 1.6 times of the mass of solid powder. The preparation method is also applicable to two application processes including a roll coating process and a spray coating process; compared with that of a traditional recipe paint coating process, the rejection rate is low; after the curing, the adhesive force and the hardness of a coating are obviously superior to those of the traditional heat insulation coating; the coating is thicker in single-time operation; the production efficiency is high; the multi-time overlay coating can be carried out according to use requirements, and the coating thickness is increased. Wide application prospects are realized in national defense and military industry and civil industry.

Owner:JINXI IND GRP

Monodispersed nano magnetic bead used for rapid sample pretreatment and preparation method thereof

ActiveCN104209087ALarge fragmentFragment greatlyOther chemical processesInorganic material magnetismChemical structurePathogenic microorganism

The invention discloses monodispersed nano magnetic beads for rapid sample pretreatment and a preparation method thereof. The nano magnetic material has chemical structure of Fe3O4@SiO2-AEAPS, is a core-shell multifunctional magnetic nano material with abilities of targeting transport, monodispersity and specific combination, and can quickly and efficiently enrich pathogenic microorganisms in field diagnosis of infectious diseases. Furthermore, the monodispersed nano magnetic bead can be used for nucleic acid extraction of the obtained pathogen. The material provided by the invention is a high-tech product combining nanotechnology, molecular biological technology and biological medicine.

Owner:INST OF PLA FOR DISEASE CONTROL & PREVENTION

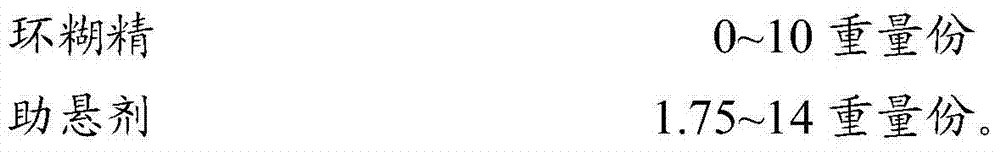

Wettable experimental pullorum evapotranspiration and preparation method thereof

InactiveCN103520267ASettling speed is slowEasy to usePowder deliveryDigestive systemMedicineSuspending Agents

The invention relates to the technical field of veterinary medicine preparation, in particular to wettable experimental pullorum evapotranspiration and a preparation method thereof. A suspending agent is added to the wettable experimental pullorum evapotranspiration based on original effective composition of herbs, and through reasonable medicine matching, the wettable experimental pullorum evapotranspiration is easy to scatter evenly in water, and beneficial to dosing during water drinking. Compared with commercially available experimental pullorum evapotranspiration, the wettable experimental pullorum evapotranspiration is good in therapeutic effect and convenient to use. The preparation method of the wettable experimental pullorum evapotranspiration is simple in technology, low in production cost, and suitable for industrial mass production.

Owner:CHENGDU QIANKUN VETERINARY PHARMA +1

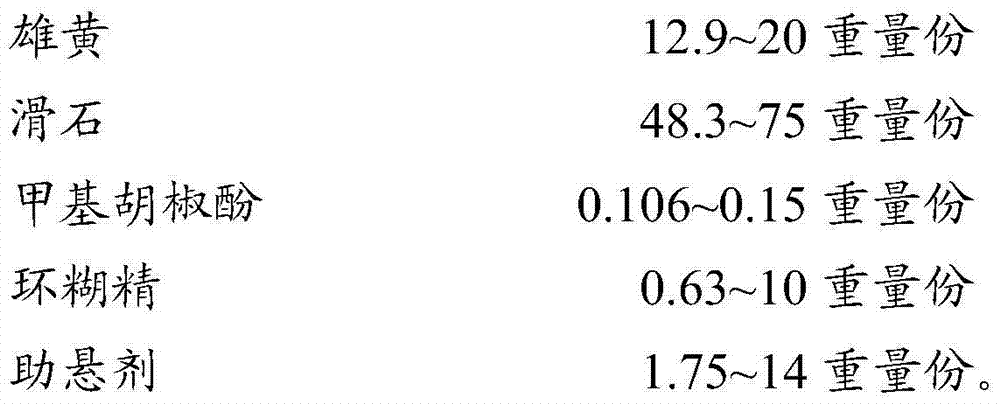

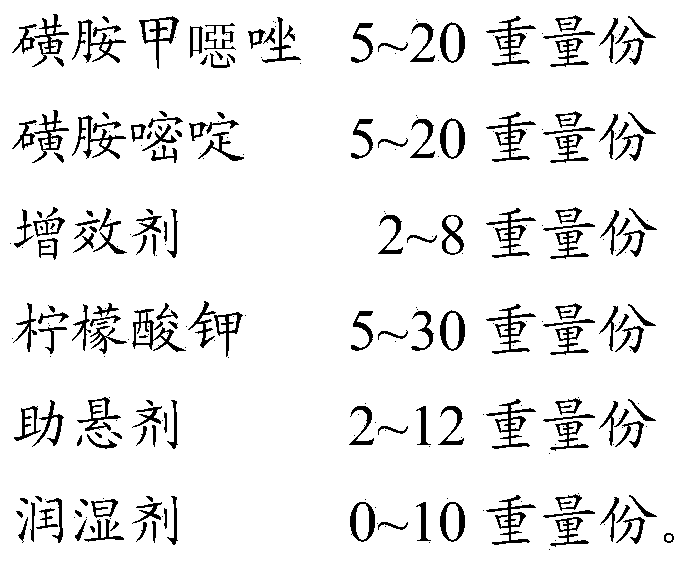

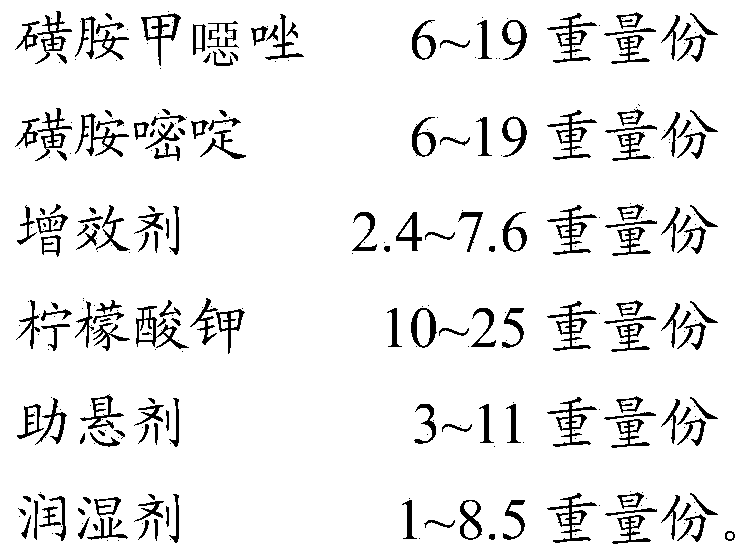

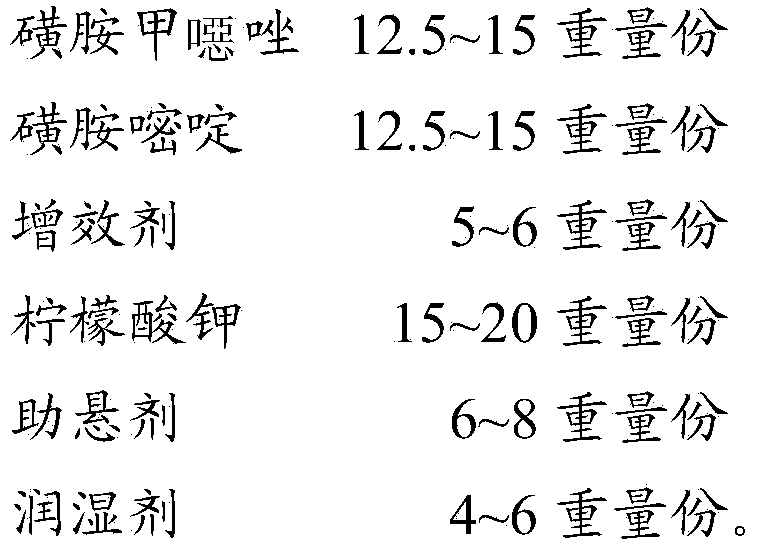

Wettable sulfamethoxazole trimethoprim powder and preparation method thereof

ActiveCN103536604AImprove stabilityGood dispersionAntibacterial agentsPowder deliverySide effectMedicine

The invention relates to the technical field of veterinary medicine preparation, and particularly relates to wettable sulfamethoxazole trimethoprim powder and a preparation method thereof. The wettable sulfamethoxazole trimethoprim powder provided by the invention is added with potassium citrate, a suspending agent and a wetting agent on the basis of effective components of the original medicine; by reasonable medicine proportioning, the invention provides the wettable sulfamethoxazole trimethoprim powder which is easy to disperse evenly in water and convenient to take with water. Compared with commercially available sulfamethoxazole trimethoprim premix, the wettable sulfamethoxazole trimethoprim powder is good in therapeutic effect, convenient to use and small in toxic and side effects. The invention also provides the preparation method of the wettable sulfamethoxazole trimethoprim powder, and the preparation method is simple in technology, low in production cost and suitable to industrialized production.

Owner:CHENGDU QIANKUN VETERINARY PHARMA +1

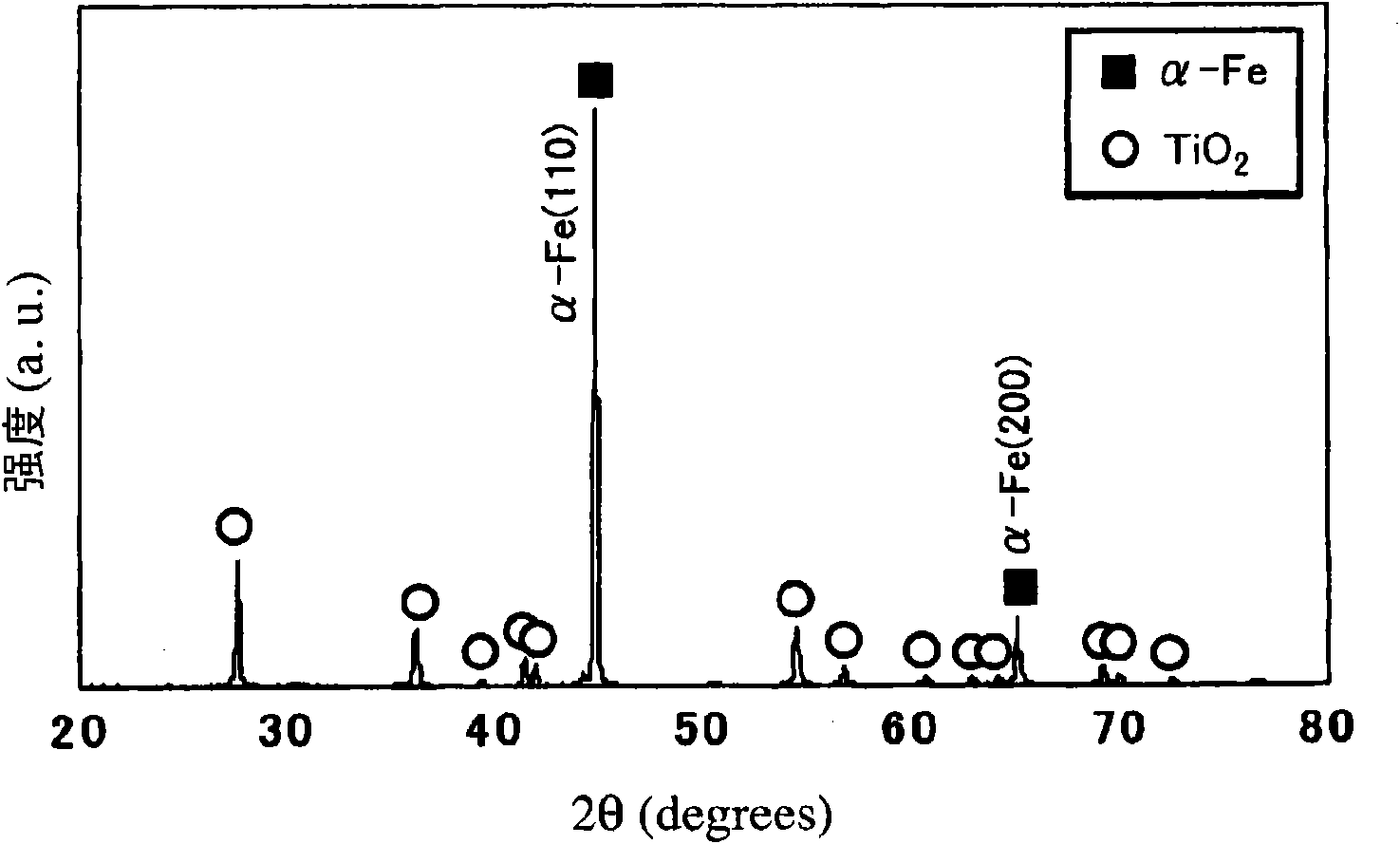

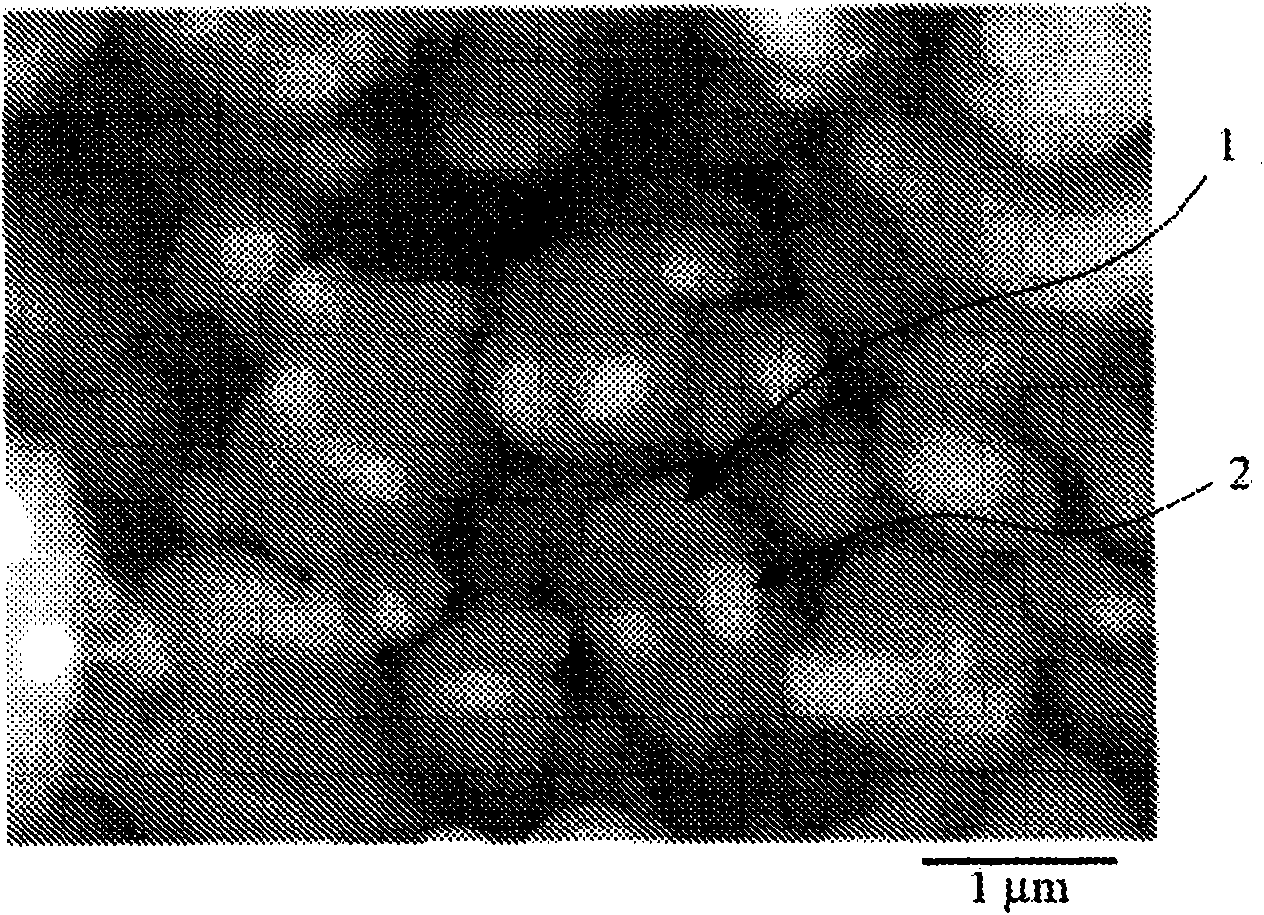

Coated fine metal particle and process for producing the same

InactiveCN101977711AImprove corrosion resistanceImprove capture abilityMetal-working apparatusThin material handlingFree energiesMetal particle

A process for producing coated fine metal particles comprising core particles of a metal which have been coated with a titanium oxide and a silicon oxide in this order, characterized by: mixing a powder comprising TiC and TiN with a powder of an oxide of a metal (M) having a standard free energy of formation (delta GM-O) satisfying the relationship delta GM-O>delta GTiO2, heat-treating the mixture in a non-oxidizing atmosphere to reduce the metal (M) oxide with the powder comprising TiC and TiN and coat the surface of the resultant metal (M) particles with a titanium oxide, subsequently coating the surface of the titanium oxide coating with a silicon oxide, and classifying the resultant particles so as to obtain particles having a median diameter (d50) of 0.4-0.7 [mu]m and a coefficient of variation indicating particle diameter distribution width [=(standard deviation) / (average particle diameter)] of 35% or less. Also provided are coated fine metal particles comprising core particles of a metal which have been coated with a titanium oxide and a silicon oxide in this order, characterized by having a median diameter (d50) of 0.4-0.7 [mu]m and a coefficient of variation indicating particle diameter distribution width [=(standard deviation) / (average particle diameter)] of 35% or less.

Owner:PROTERIAL LTD

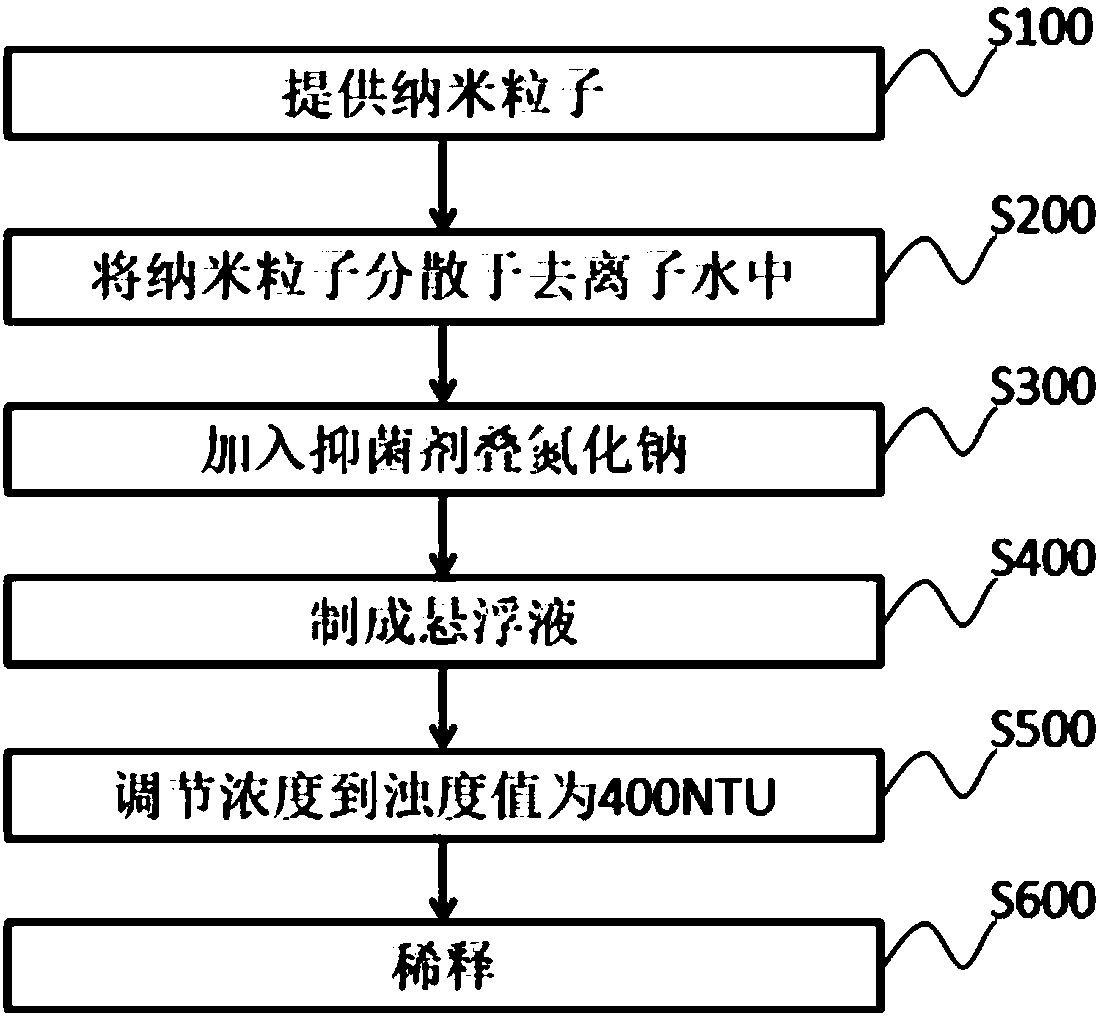

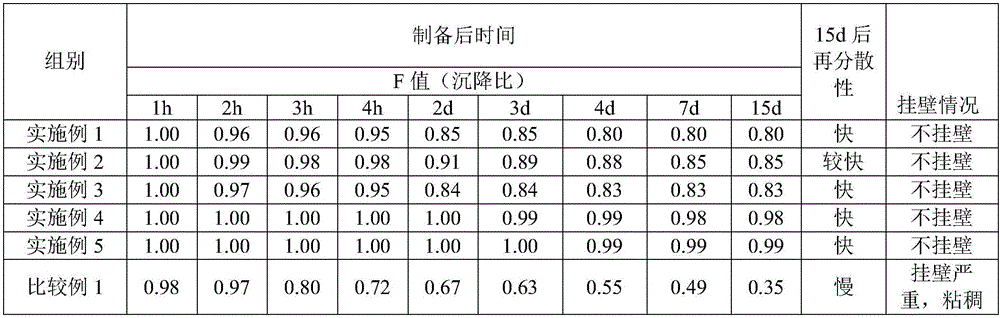

Polymer suspension turbidity standard substance and preparing method thereof

ActiveCN108458992ALow turbidityImprove stabilityPreparing sample for investigationScattering properties measurementsPolymer scienceHigh density

The invention discloses a polymer suspension turbidity standard substance and a preparing method thereof. Nano particles with high-density negative or positive charges on the surfaces are dispersed into deionized water and a bacteriostatic agent is added to prepare polymer suspension, and the concentration is adjusted to obtain polymer turbidity standard liquid of which the turbidity value is 400NTU. The polymer turbidity standard liquid of which the turbidity value is 400 NTU and zero-turbidity water are diluted proportionally to obtain the polymer suspension turbidity standard substance ofwhich the nominal value is 0.5-100 NTU. The polymer suspension turbidity standard substance has the advantages of having the low turbidity value smaller than or equal to 100 NTU, being high in stability, free of cold storage, convenient to transport and use, and capable of being stored at the normal temperature, and having a stable period as long as 2 years.

Owner:BEIJING HUOLIYUAN TECH CO LTD

Bait for juvenile sea cucumber in growing periodand preparation method of bait

The invention relates to a bait for a juvenile sea cucumber in the growing period and a preparation method of the bait. The bait is prepared from the following components in weight percentage: 60% of sargassumthunbergii powder, 10% of common mussel meat powder, 4% of soybean meal, 6% of defatted fish meal, 2% of spirulina powder, 1.5% of baker's yeast powder, 0.5% of compounded mineral substance, 0.5% of multivitamin powder, 1.5% of immune polysaccharides and 14% of dry sea mud powder. In the bait for the juvenile sea cucumber in the growing period, the components are in mutualcompatibility, the contained nutritional ingredients can meet the rapid growing need of the juvenile sea cucumber, the juvenile sea cucumber then grows fast in the opening stage and grows to 2 mm from 0.5 mm averagely after being fed with the bait for 20 days, and the rate of survival is up to more than 80%.

Owner:WENDENG AQUATIC PROD TECH PROMOTION STATION

Fenbendazole suspension and preparation method thereof

ActiveCN106727304ASimple methodMild operating conditionsOrganic active ingredientsSolution deliveryFenbendazoleSodium benzoate

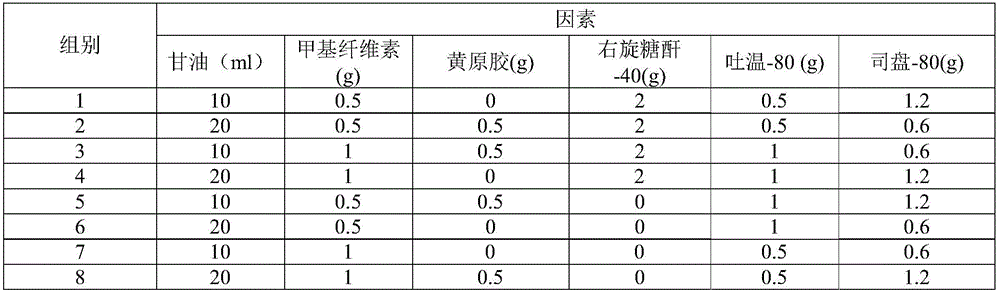

The invention provides a fenbendazole suspension. The suspension per 100ml mainly comprises 8-12g of fenbendazole, 10-25ml of glycerinum, 0.1-0.7g of methylcellulose, 0.1-1.5g of xanthan gum, 0-3g of dextran-40, 0.1-1.5g of tween-80, 0.6-1.5g of span-80, 0.1-0.3g of sodium benzoate, 1-3g of citric acid and the balance of water. A preparation method comprises the following steps: mixing and wetting fenbendazole with glycerinum, tween-80 and span-80 to form mixed liquid; and after partially dissolving sodium benzoate, citric acid and dextran-40 with part of water, adding methylcellulose and xanthan gum and uniformly mixing, mixing the mixture with the mixed liquid, and then adding residual water and uniformly mixing to obtain the suspension.

Owner:JIANGXI BOLAI PHARMACY CO LTD

Production of flocculating agent containing fluorine cation

InactiveCN101074129AIncrease the relative molecular massAvoid easy separationWater/sewage treatment by flocculation/precipitationFluorideEpichlorohydrin

Production of fluoride cation flocculating agent is carried out by dripping 30% dimethylamine solution into epoxy chloropropane at 25-35 degree while agitating, adding into cross-linking agent, agitating, raising temperature to 70 degree by 1 degree / min, keeping temperature while reacting for 4 hrs, adding into perfluoro alkyl sulfonic acid halide, and re-reacting for 2 hrs to obtain final product. It's tight, has low deposition speed, no solid-liquid separation and less filter cake water content.

Owner:SHAANXI UNIV OF SCI & TECH

Acidophilic microorganism degradation plastic master batch and preparation method thereof

The invention discloses an acidophilic microorganism degradation plastic master batch and a preparation method thereof. The acidophilic microorganism degradation plastic master batch is formed by meltpolymerization of a methyl-glycolide-lactic acid acidic monomer and an organic silicon colloid under the catalytic action of SnCl2. The acidophilic microorganism degradation plastic master batch provided by the invention has high purity and good applicability, is easily decomposed by acidophilic microorganisms, can provide survival energy for the acidophilic microorganisms, and has harmless decomposition products.

Owner:宁波俐辰新能源有限公司

An environment friendly expanded mixed feedstuff for rockfishes and method for preparing same

ActiveCN100493371CPromote rapid growthImprove digestion and absorption rateFood processingClimate change adaptationVegetable oilFish paste

Owner:GUANGDONG EVERGREEN FEED INDAL

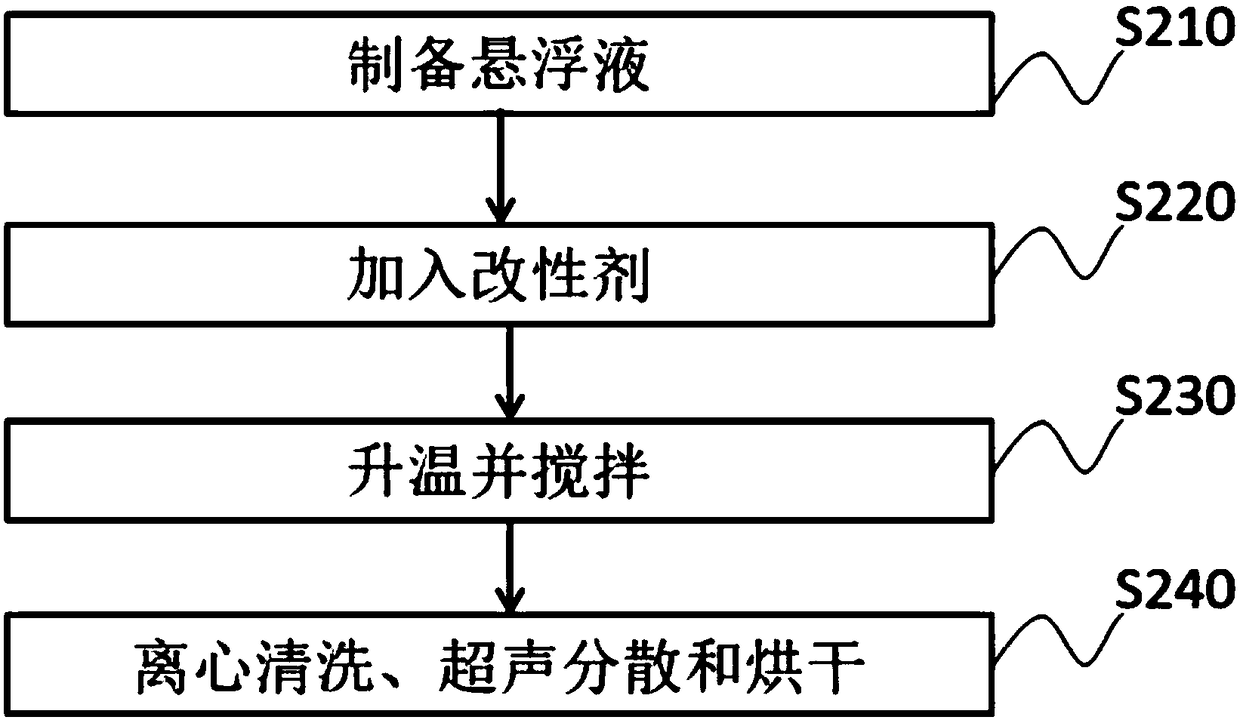

Surface modification method of aluminate yellow fluorescent powder for LED

ActiveCN104119855AGood compatibilitySettling speed is slowLuminescent compositionsAluminateNano sio2

The invention relates to a surface modification method of aluminate yellow fluorescent powder for an LED. The method comprises the following technical steps: nano SiO2 surface pretreatment; surface modification by polyethylene glycol; low-temperature sintering treatment and the like. The method specifically comprises the following steps: adding the aluminate yellow fluorescent powder into a hydrating solution of ethyl orthosilicate; after reaction, carrying out surface modification by polyethylene glycol; by using N-hexadecyl trimethyl ammonium chloride as an emulsifier, drying; and in a nitrogen atmosphere, firing at low temperature to obtain the surface modified fluorescent powder. The aluminate yellow fluorescent powder provided by the invention has the characteristics of good compatibility with carrier glue, slow settling velocity in the carrier glue, high product percent of pass and the like and can be used for surface modification of synthesizing the aluminate yellow fluorescent powder.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

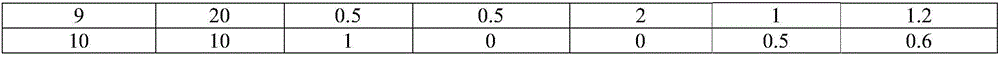

Probiotic dry suspension for feed and preparation method thereof

ActiveCN106615626ASettling speed is slowImprove physical stabilityPowder deliveryMetabolism disorderGlucose polymersWater soluble

The invention discloses a probiotic dry suspension for feed, prepared from, by weight, feed probiotics 0.5-10 billion / g, 1-5% of a suspending agent, 0.5-2% of a surfactant, and the balance of a soluble carrier; the suspending agent is carbomer, the surfactant is poloxamer, and the soluble carrier is from one or more of anhydrous glucose, water-soluble starch, and complex starch powder or Fu Mei powder. The probiotic dry suspension for feed settles slow, has good physical stability, meets the quality requirements of suspensions, is simple to prepare, has stable quality, is convenient to use and has a promising application prospect.

Owner:WUHAN XINLIANDA BIOLOGY

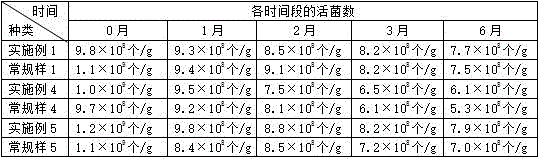

Emamectin benzoate microcapsule suspending agent and preparation method thereof

ActiveCN112155011AReduce dispersionHigh encapsulation efficiencyBiocideArthropodicidesMedicineFirming agent

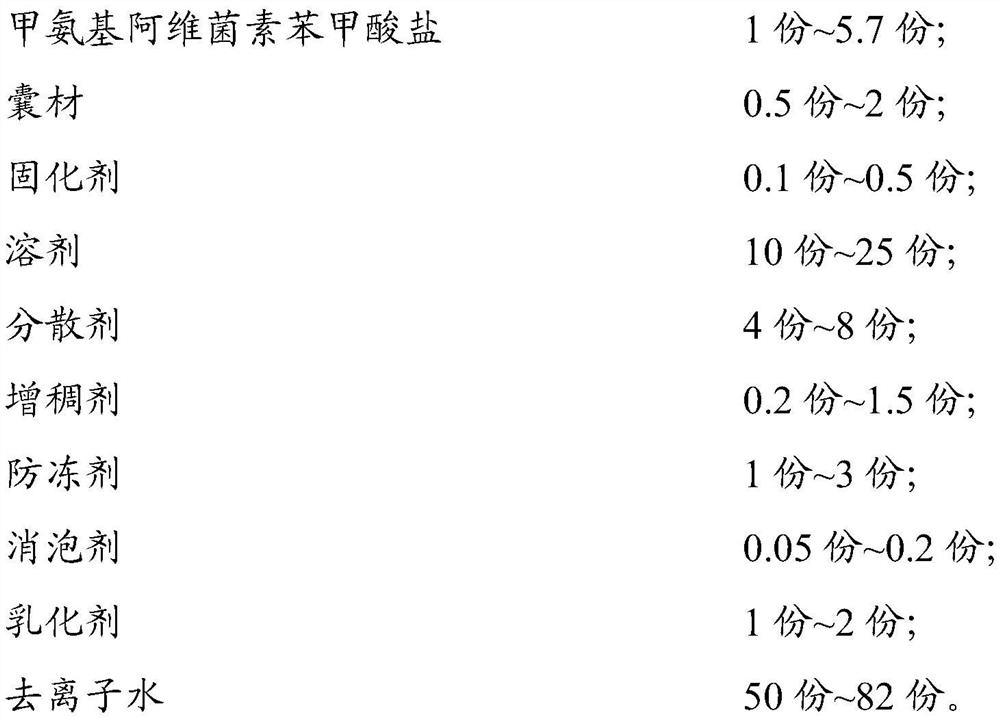

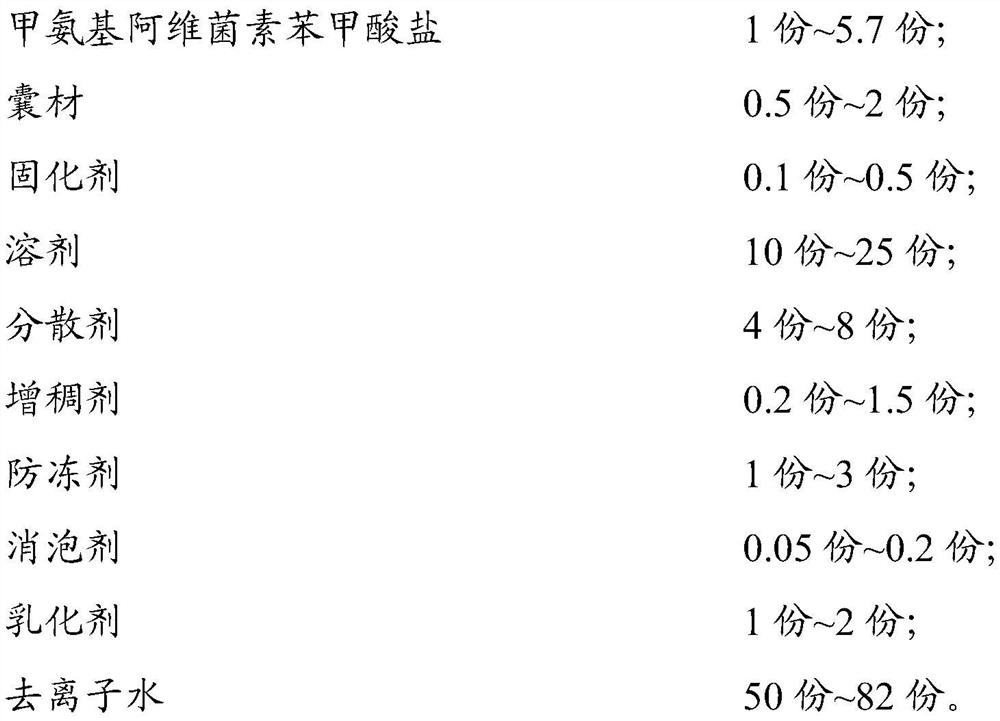

The invention provides an emamectin benzoate microcapsule suspending agent and a preparation method thereof. The microcapsule suspending agent is prepared from the following components in parts by mass: 1 to 5.7 parts of emamectin benzoate; 0.5 to 2 parts of a capsule material; 0.1 to 0.5 part of a curing agent; 10 to 25 parts of a solvent; 4-8 parts of a dispersant; 0.2 to 1.5 parts of a thickening agent; 1-3 parts of an antifreezing agent; 0.05 to 0.2 part of a defoaming agent; 1-2 parts of an emulsifier; and 50 to 82 parts of deionized water. The microcapsule suspending agent is high in encapsulation efficiency and large in drug loading capacity.

Owner:HUIZHOU YINNONG TECH

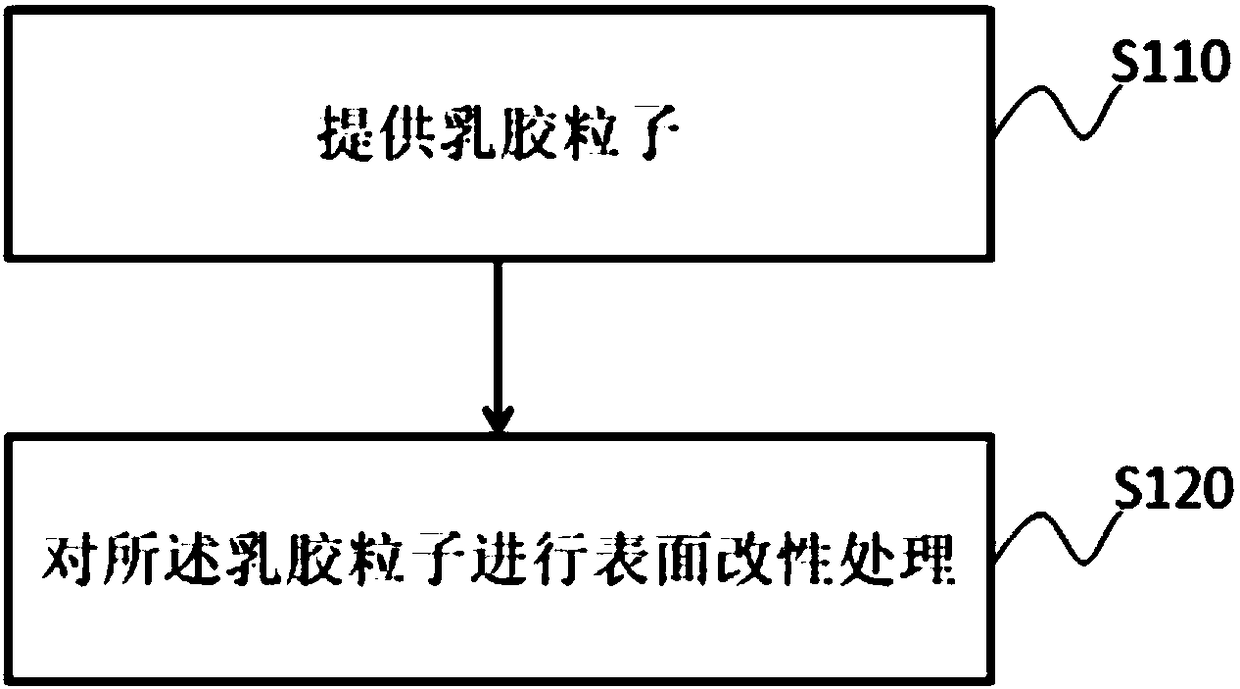

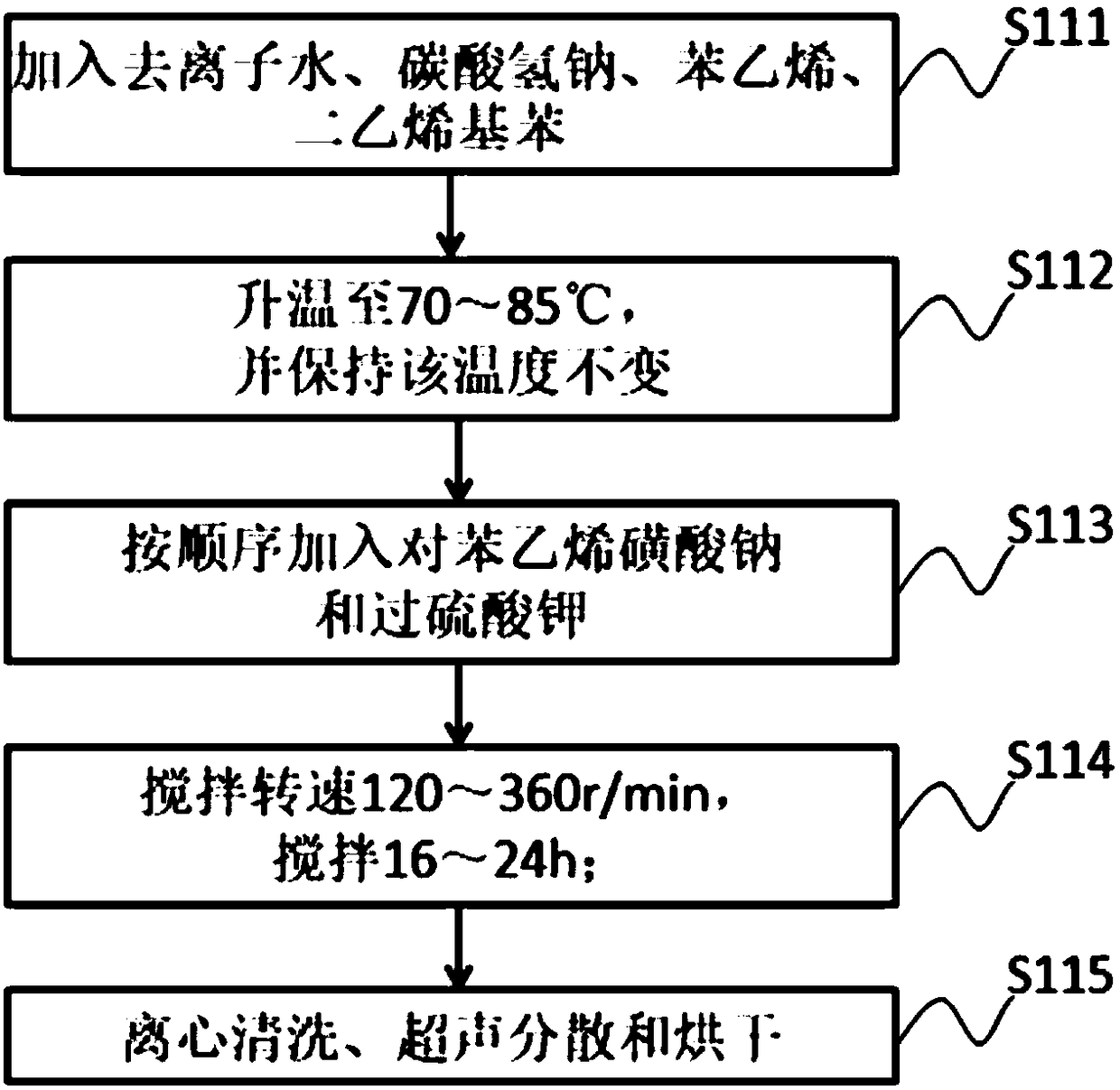

Nano particle for polymer turbidity standard substance and preparation method thereof

ActiveCN108285506ANo reunionSettling speed is slowScattering properties measurementsTransmissivity measurementsHigh densityTurbidity

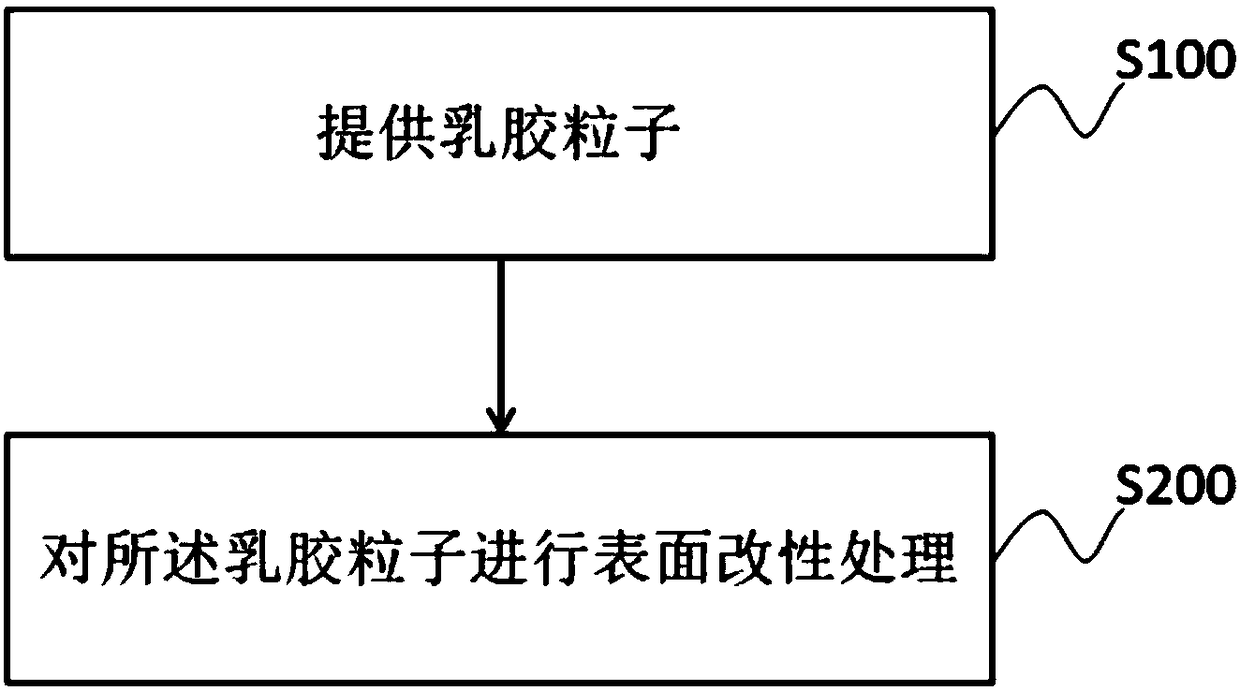

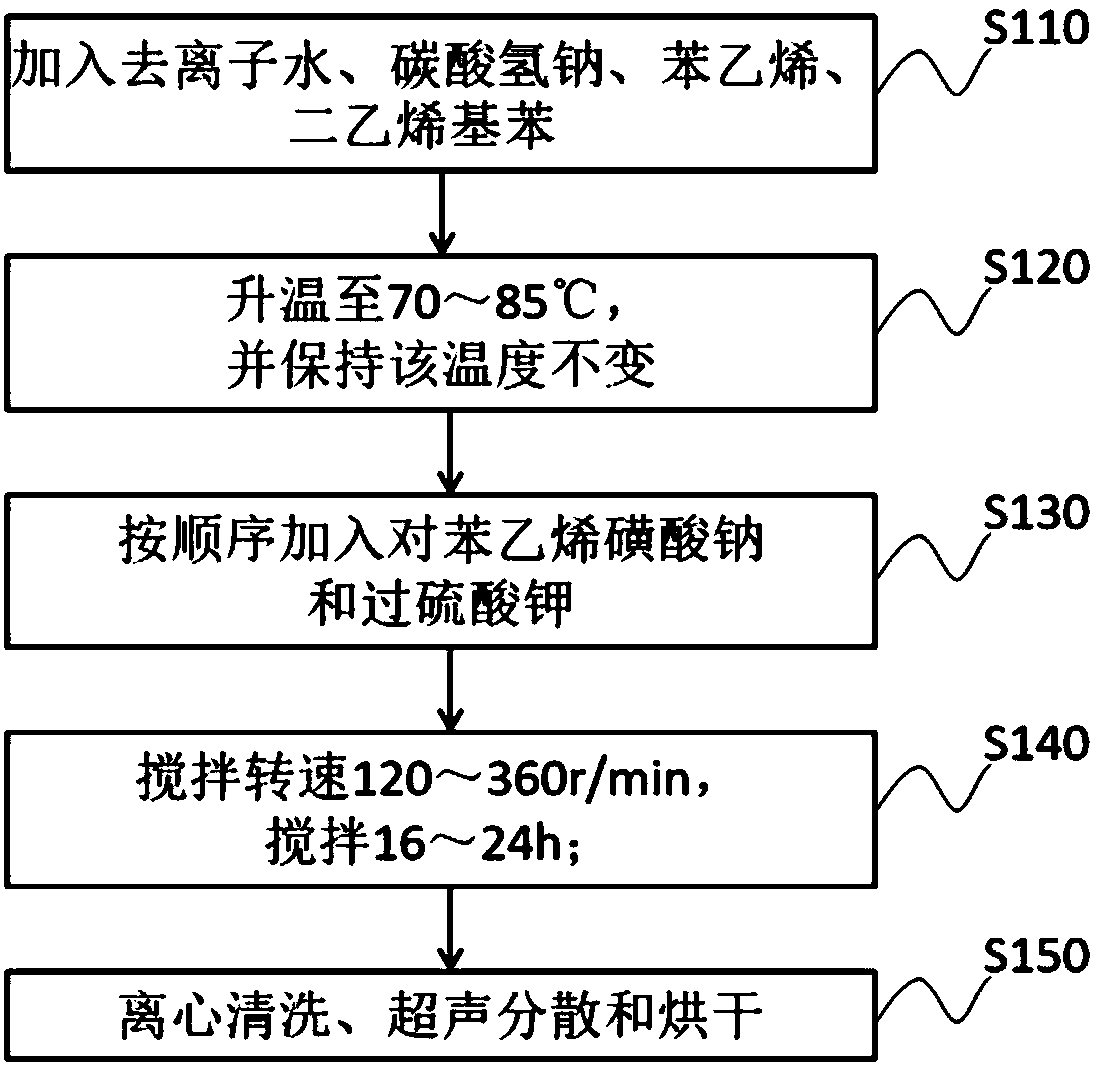

The invention provides a nano particle for a polymer turbidity standard substance and a preparation method thereof. The nano particle is a monodisperse crosslinked polystyrene latex particle having aparticle diameter of 100-500 nm, the monodispersity is good (PDI<0.1), the sphericity is high, and the surface is modified with high-density like charges. The preparation method of the nano particle includes the step of conducting surface modification treatment on latex particles prepared by polymerization reaction. By adopting the nano particle to prepare low-turbidity (<=100 NTU) polymer turbidity standard solution, the stability is good, the storage period is long, there is no need for refrigeration, and the transportation and use are convenient.

Owner:BEIJING HAIAN HONGMENG STANDARD SUSNCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com