Doped large-particle cobalt carbonate and preparation method thereof

A large particle, cobalt carbonate technology, applied in the direction of cobalt carbonate, etc., to achieve good growth consistency, reduce aluminum segregation, and slow sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

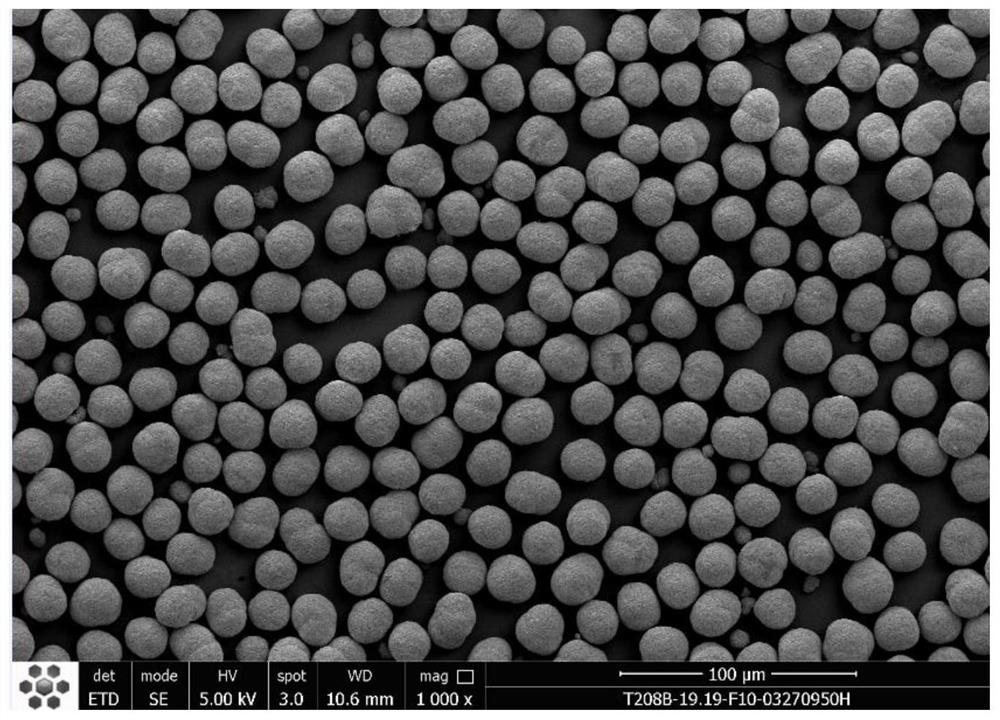

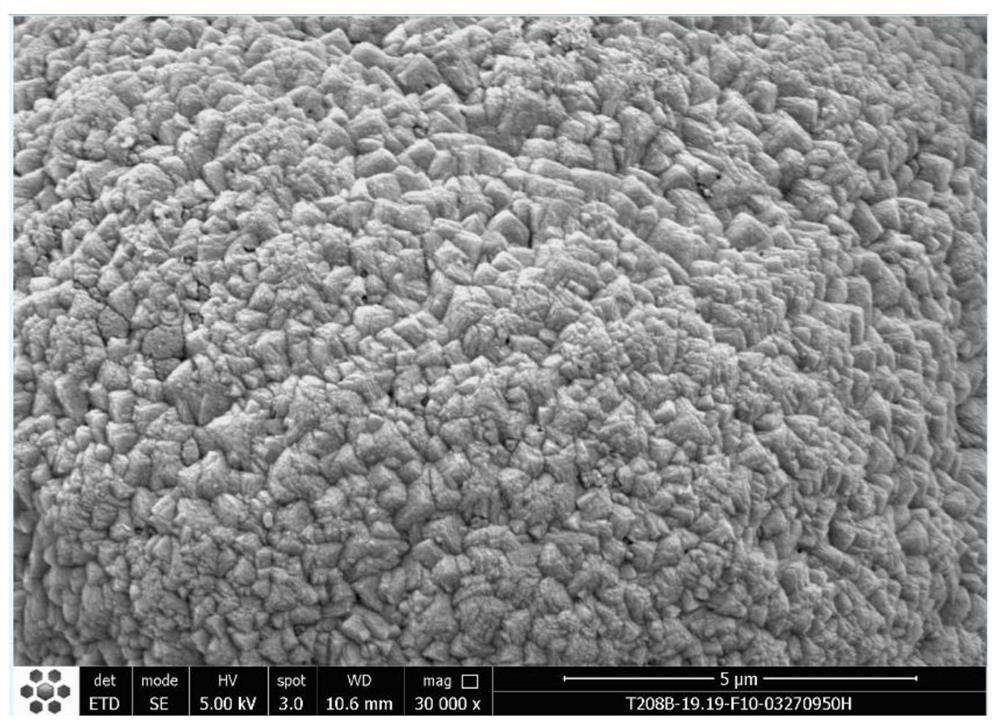

[0056] A doped large particle cobalt carbonate, the molecular formula is [CoCO 3 ] 0.987 ·[Co 6 Al 2 CO 3 (OH) 16 4H 2 O] 0.013 ,Such as figure 1 , figure 2 As shown, its morphology is spherical secondary particles composed of nano-scale primary conical particles, and the range of particle size distribution of the spherical secondary particles is as follows: (D90-D10) / D50=0.4.

[0057] figure 1 It is the SEM picture of the doped large-grained cobalt carbonate enlarged 1000 times in Example 1. It can be clearly seen that the secondary particles of the doped large-grained cobalt carbonate are uniform spherical particles, and no filamentous or flake Al segregation is found on the surface .

[0058] figure 2 It is the SEM image of the doped large-grained cobalt carbonate enlarged 20,000 times in Example 1, and it can be clearly seen that the primary particle of the doped large-grained cobalt carbonate is in the shape of a nanoscale cone.

[0059] D50=19.31μm, D10=16....

Embodiment 2

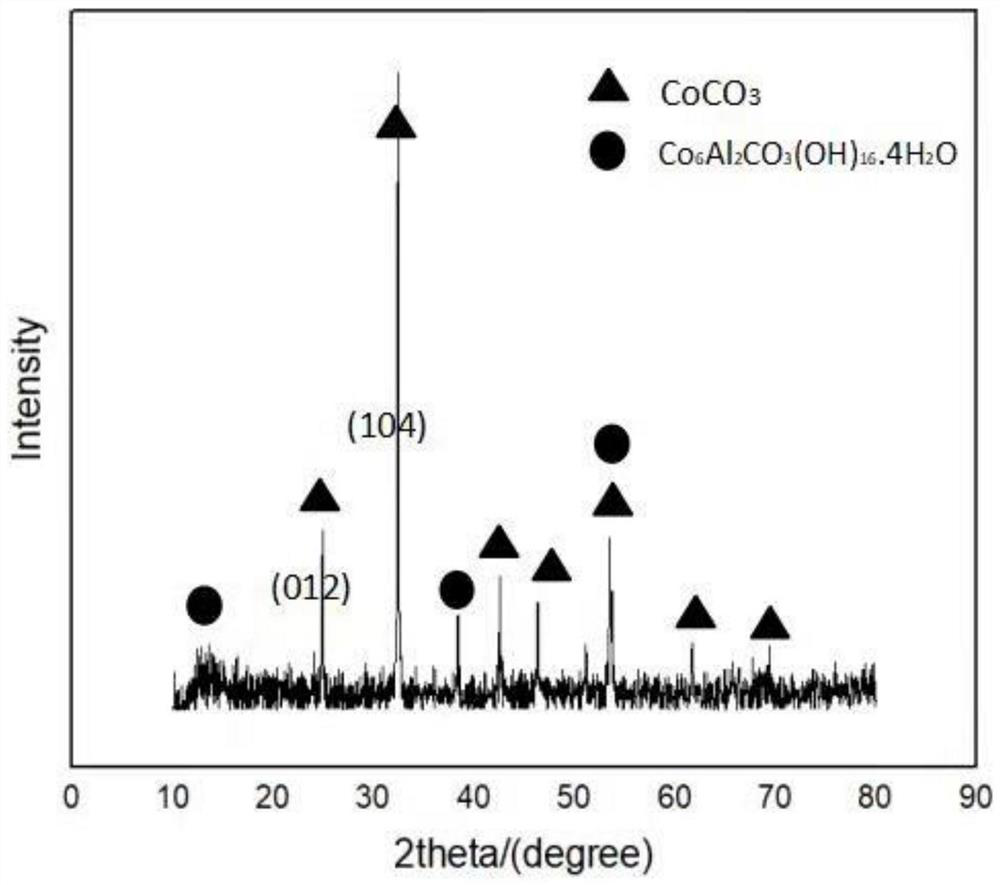

[0077] A doped large particle cobalt carbonate, the molecular formula is [CoCO 3 ] 0.989 ·[Co 6 Al 2 CO 3 (OH) 16 4H 2 O] 0.011 , the shape of which is spherical secondary particles composed of nano-scale primary conical particles, and the range of particle size distribution of the spherical secondary particles is as follows: (D90-D10) / D50=0.404.

[0078] D50=19.28μm, D10=16.11μm, D90=23.90μm of the above-mentioned large-grained cobalt carbonate, and the tap density is 1.90g / cm 3 . The large particle cobalt carbonate crystal structure is characterized by XRD, the half peak width of the 012 peak is 0.214, the half peak width of the 104 peak is 0.192, the ratio of the half peak width of the 012 peak and the 104 peak is 1.115, and the intensity ratio of the 012 peak and the 104 peak is 0.322.

[0079] A preparation method of high-voltage doped large particle cobalt carbonate, comprising the following steps:

[0080] S1. Nucleation:

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com