Polymer suspension turbidity standard substance and preparing method thereof

A standard substance and polymer technology, applied in the preparation of test samples, measurement of scattering characteristics, measurement of transmittance, etc., can solve the problems of variable value during storage period, great harm to human body, and influence of turbidity value, etc., to achieve The effect of slow particle settling speed, convenient transportation and use, and small change in turbidity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

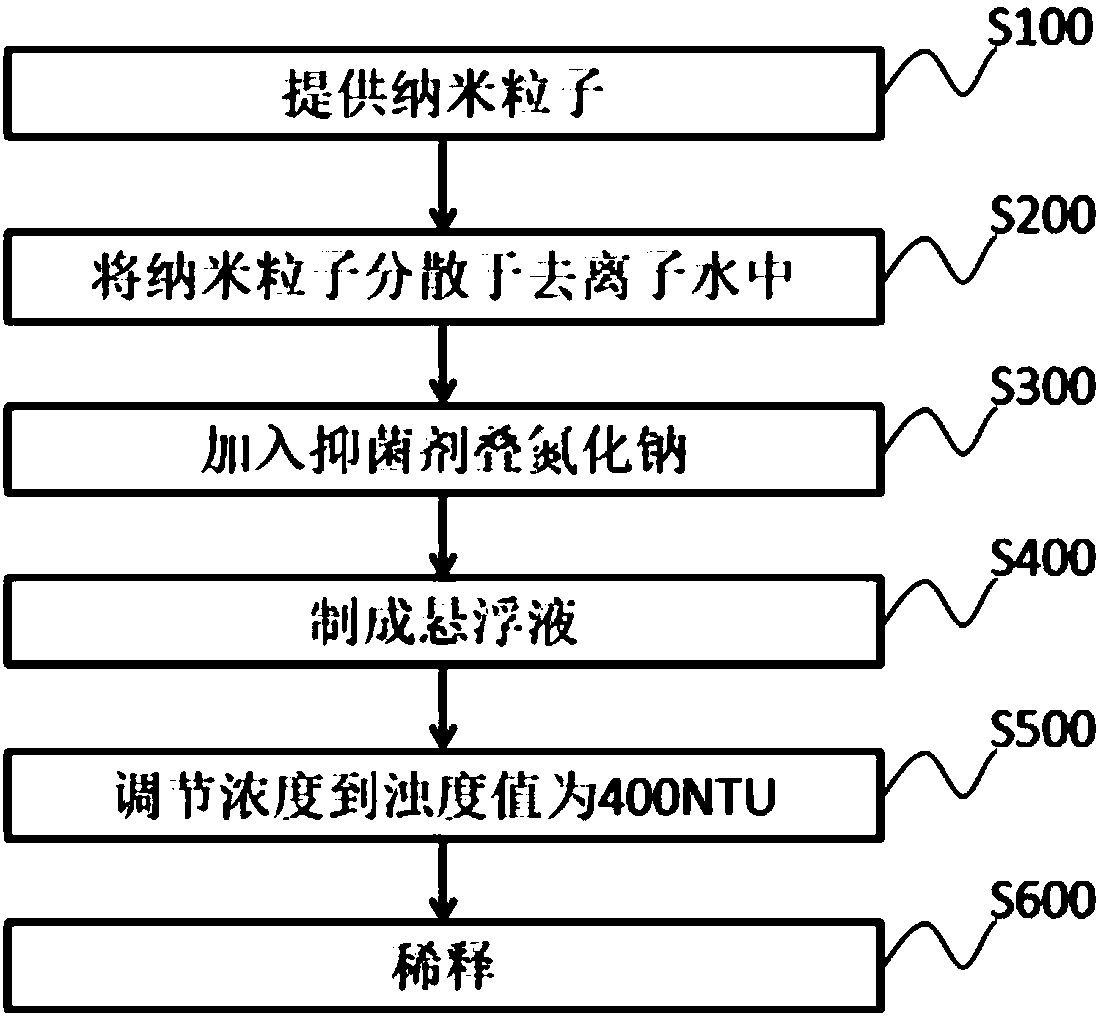

[0048] Such as figure 1 Shown, the preparation method of polymer suspension turbidity standard substance of the present invention comprises:

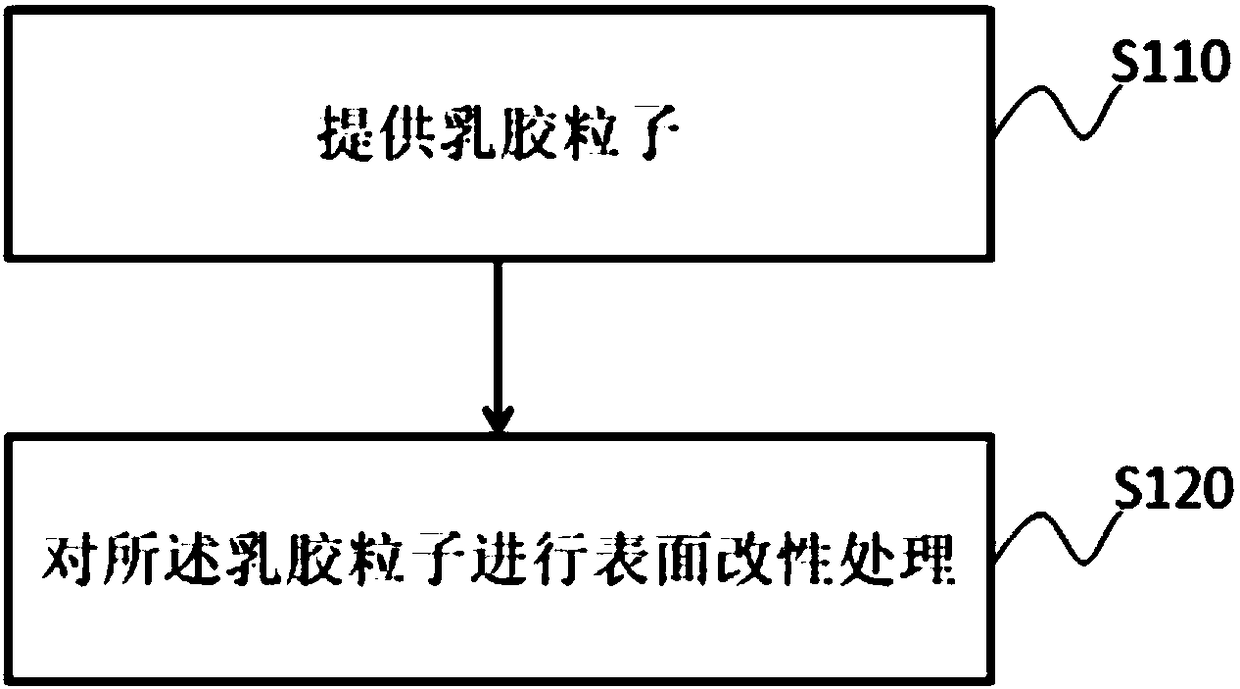

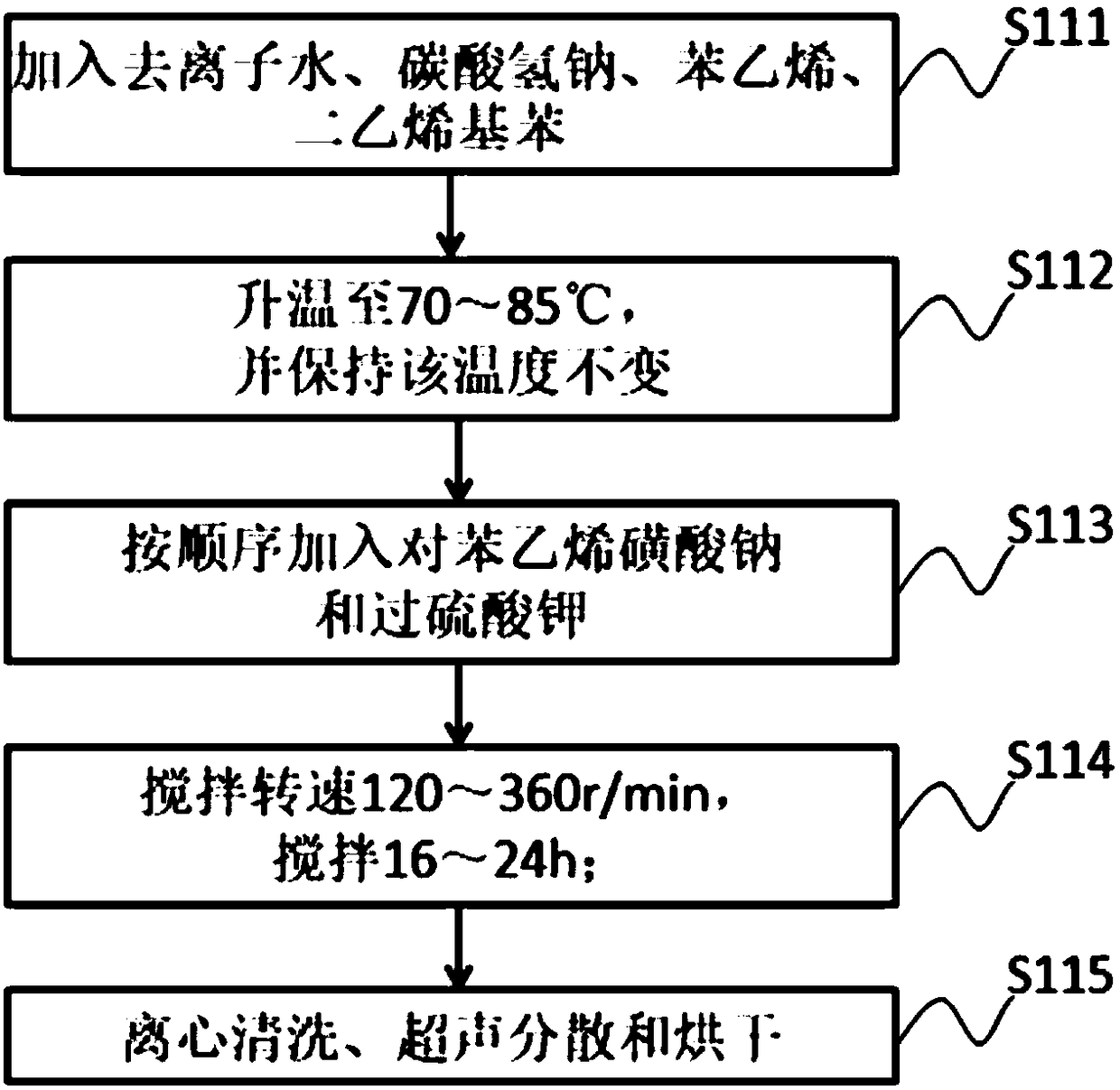

[0049] S100, providing nanoparticles. Wherein, the nanoparticles are monodisperse cross-linked polystyrene latex particles with a particle diameter of 100-500 nm and a density of 1.05 g / cm 3 And its surface is decorated with high-density same-sex charges: the Zeta potential of negative charges is between -60mV and -40mV; or the Zeta potential of positive charges is between 40mV and 60mV.

[0050] Nanoparticles can be purchased directly or prepared by polymerization.

[0051] S200, dispersing the nanoparticles in deionized water.

[0052] S300, adding the antibacterial agent sodium azide.

[0053] S400, making a polymer suspension. The preparation method is mechanical stirring and ultrasonic treatment.

[0054]S500. Adjust the concentration to a turbidity value of 400 NTU.

[0055] S600, dilution. The polymer turbidity standard s...

Embodiment 1

[0087] Embodiment 1, nominal value is 10NTU polymer suspension turbidity standard substance

[0088] The polymer suspension turbidity standard substance with a nominal value of 10NTU is a suspension of nanoparticles in deionized water; the nanoparticles are monodisperse cross-linked polystyrene latex particles with a particle diameter of 220nm; the nanoparticles density 1.05g / cm 3 ; The surface of the nanoparticles is modified with high-density negative charges, and the Zeta potential is -60mV~-40mV.

[0089] The preparation method of above-mentioned polymer suspension turbidity standard substance comprises the following steps:

[0090] (1) Nanoparticles are provided. Among them, the nanoparticles use a particle size of 220nm and a density of 1.05g / cm 3 And the surface is modified with high-density negative charge monodisperse cross-linked polystyrene latex particles.

[0091] (2) Disperse the nanoparticles in deionized water.

[0092] (3) Add the bacteriostatic agent sod...

Embodiment 2

[0098] Embodiment 2, nominal value is 50NTU polymer suspension turbidity standard substance

[0099] The polymer suspension turbidity standard substance with a nominal value of 50NTU is a suspension of nanoparticles in deionized water; the nanoparticles are monodisperse cross-linked polystyrene latex particles with a particle diameter of 450nm; the nanoparticles have a density 1.05g / cm 3 ; The surface of the nanoparticles is modified with high-density positive charges, and the Zeta potential is 40mV-60mV.

[0100] (1) Nanoparticles are provided. Among them, the nanoparticles use a particle size of 450nm and a density of 1.05g / cm 3 And the surface is modified with high-density positive charge monodisperse cross-linked polystyrene latex particles.

[0101] (2) Disperse the nanoparticles in deionized water.

[0102] (3) Add the bacteriostatic agent sodium azide.

[0103] (4) Make a polymer suspension. The preparation method is mechanical stirring and ultrasonic treatment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com