Method for preparation of coal water slurry or water coke slurry by two-stage dosing

A technology of water coke slurry and coal water slurry, which is applied in the field of water coke slurry and coal water slurry manufacturing, can solve the problems of not considering changes such as dissociation, etc., and achieve the effect of high popularization and application value, convenient operation and improving grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

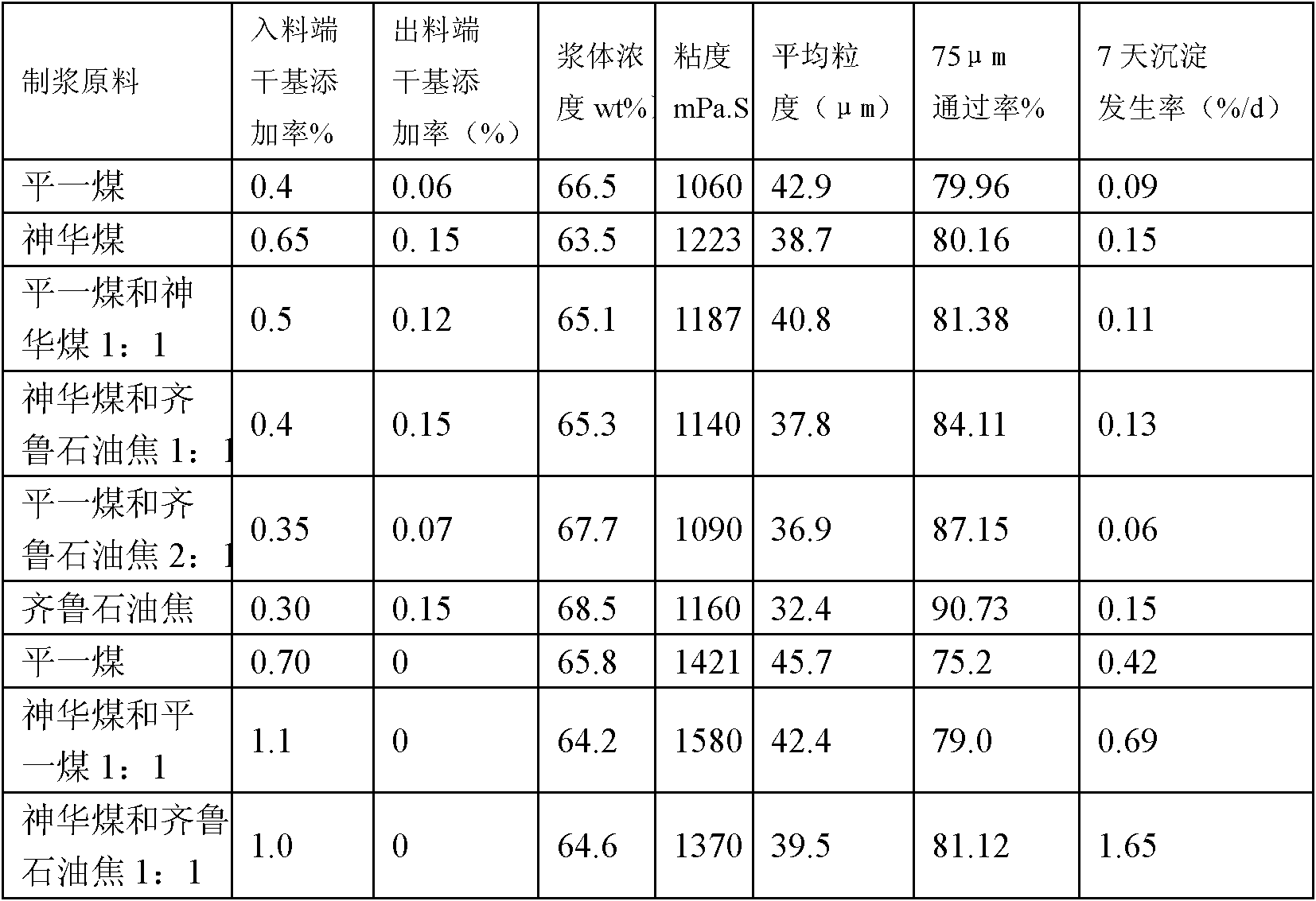

Embodiment 1

[0010] Continuous coal-water slurry production is carried out on the Φ3000*13000 special mill for coal-water slurry. The leveling coal is 45.5 tons per hour, the water is 15 tons, and 650 kg of additives (25% naphthalenesulfonate) are added to the feed end of the mill. A mixture of acid formaldehyde copolymer and lignosulfonate with a weight ratio of 2:1). Add 243 kg of additives (10% sodium hexametaphosphate and sodium polyacrylate with a weight ratio of 2:1) at the discharge end of the mill. Solution). Take samples to determine the concentration, viscosity, and particle size of the coal water slurry, and observe the stability.

Embodiment 2

[0012] Continuous coal-water slurry production is carried out on a Φ3000*13000 coal-water slurry special mill. The amount of Shenhua coal is 42.5 tons per hour, the water is 18 tons, and 1000 kg of additives (25% naphthalenesulfonate) are added to the feed end of the mill. The weight ratio of acid formaldehyde copolymer and sodium humate is 8:2), and 580 kg of additives are added to the discharge end of the mill (the weight ratio of 10% sodium hexametaphosphate and sulfonated acetone formaldehyde copolymer is 1: 1 mixed solution). Take samples to determine the concentration, viscosity, particle size, and observe the stability.

Embodiment 3

[0014] Continuous coal-water slurry production is carried out on a Φ3000*13000 special mill for coal-water slurry. 44.1 tons of mixed coal with a weight ratio of 1:1 between one coal and Shenhua coal are fed per hour, and the water input is 16.1 tons. The feed end of the mill Add 800 kilograms of additives (25% naphthalenesulfonic acid formaldehyde copolymer and naphthalene anthracene sulfonic acid formaldehyde copolymer with a weight ratio of 1:1 mixed solution), and add 480 kilograms of additives (10% sodium hexametaphosphate) to the discharge end of the mill Solution). Take samples to determine the concentration, viscosity, particle size, and observe the stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com