Flame-retardant glass fiber-reinforced HDPE/PA66 alloy material with high CTI value and high GWIT value

A technology of alloy materials and glass fiber, which is applied in the field of alloy materials, can solve the problems of unsuitable electricity use environment, low CTI value and GWIT value, etc., achieve high tracking index, improve oxidation resistance, and prevent decomposition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

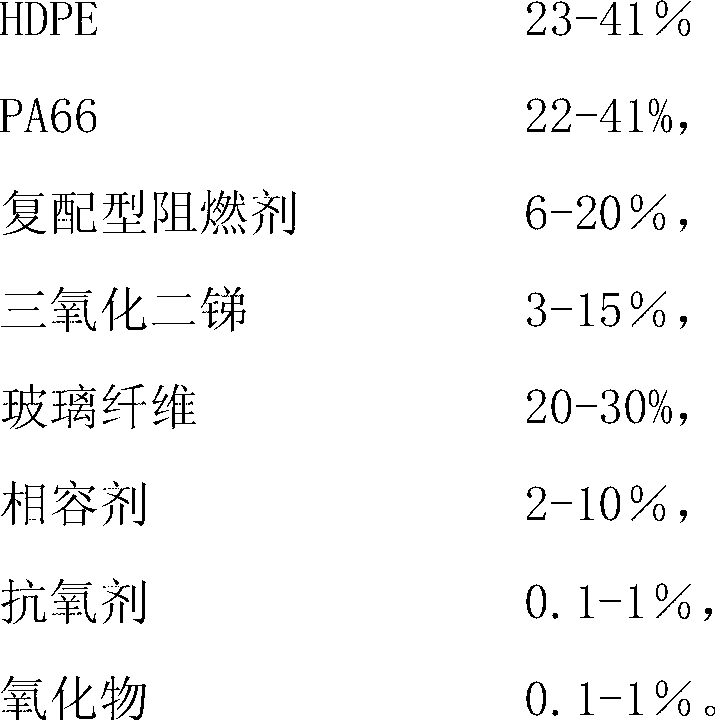

Method used

Image

Examples

Embodiment 1~6

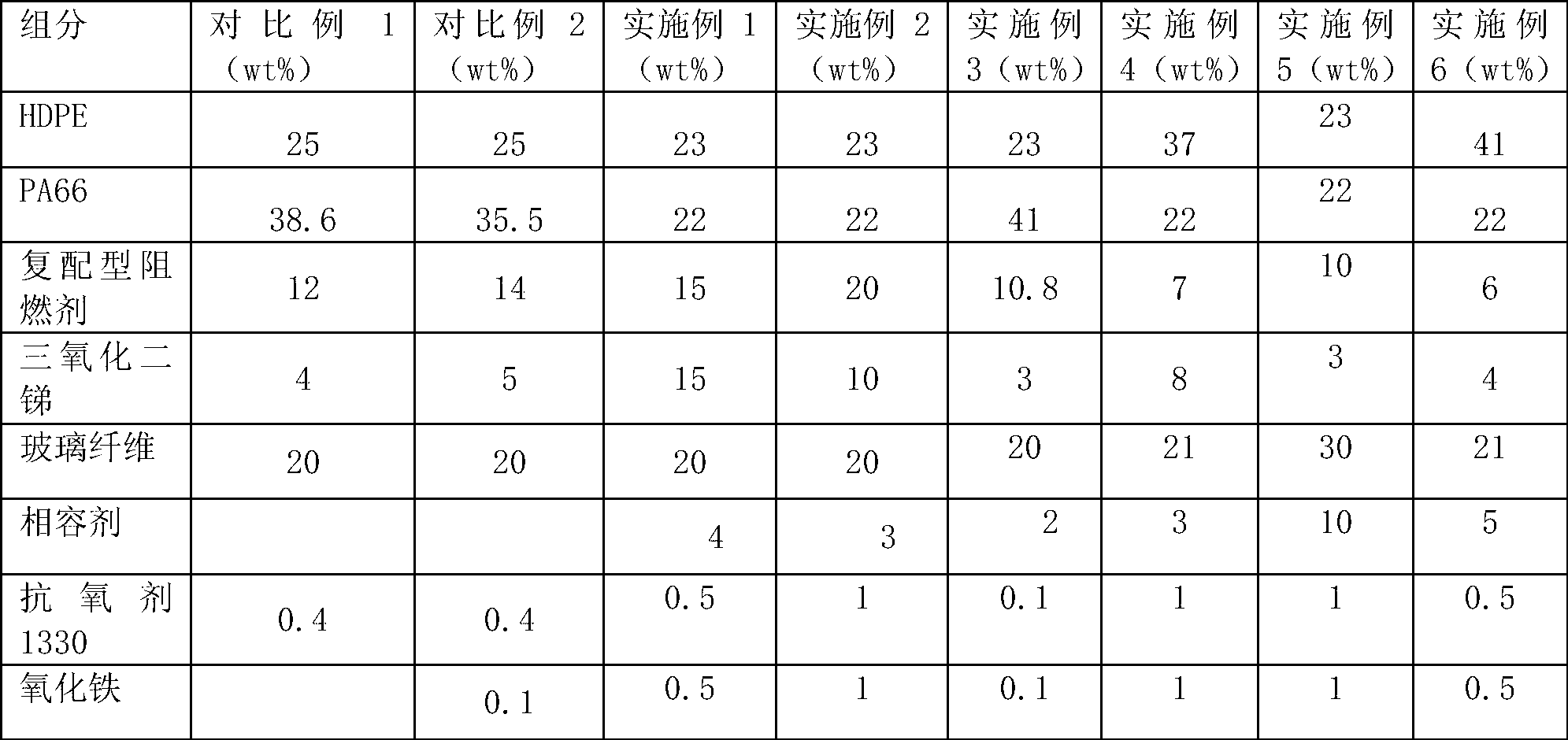

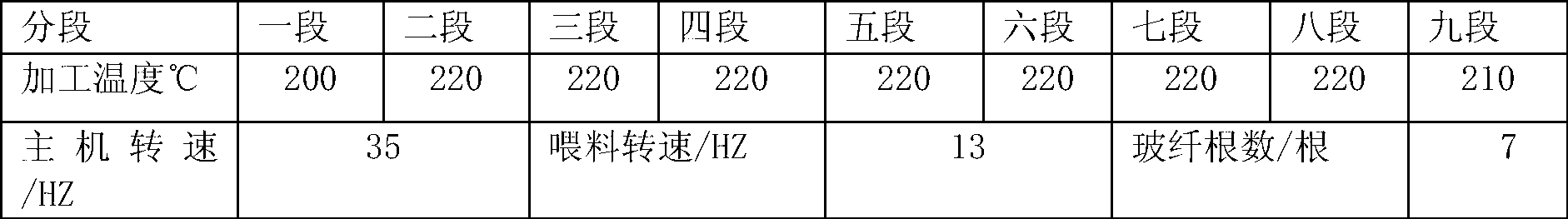

[0020] The raw materials and weight percentage content of Examples 1-2 are as shown in Table 1; The raw materials are weighed according to the weight percentage content; put into a high mixer and mix for 2-5 minutes, discharge, and then extrude with a twin-screw Extrude and granulate to produce flame-retardant glass fiber reinforced HDPE / PA66 alloy material with high CTI value and high GWIT value; the processing temperature is 220-240°C, and the screw speed is 30-40Hz; the specific processing conditions are shown in Table 2 As shown, the test results of the prepared samples are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com