Reoriented overheat air vent for reducing NO2 produced from coal powder burner

An air port and burner technology, which can be applied in the direction of combustion type, combustion equipment, combustion method, etc., can solve problems such as increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

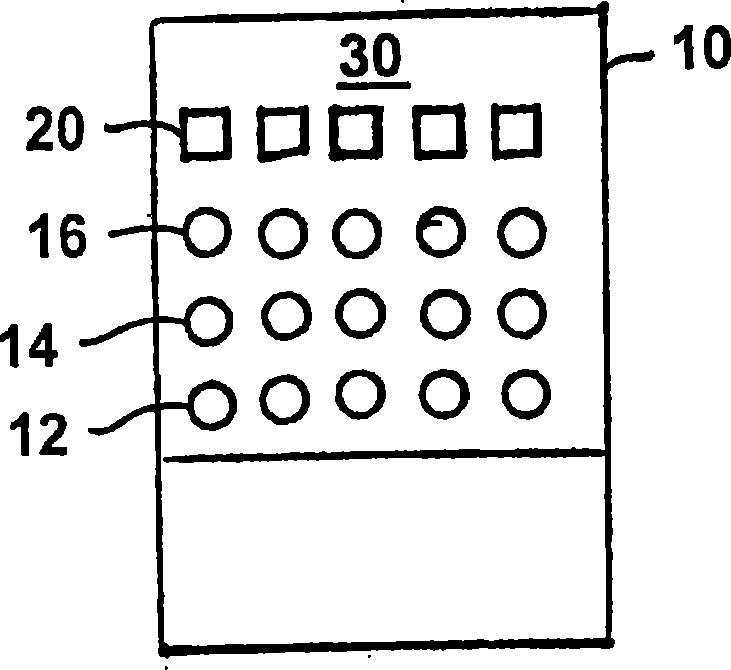

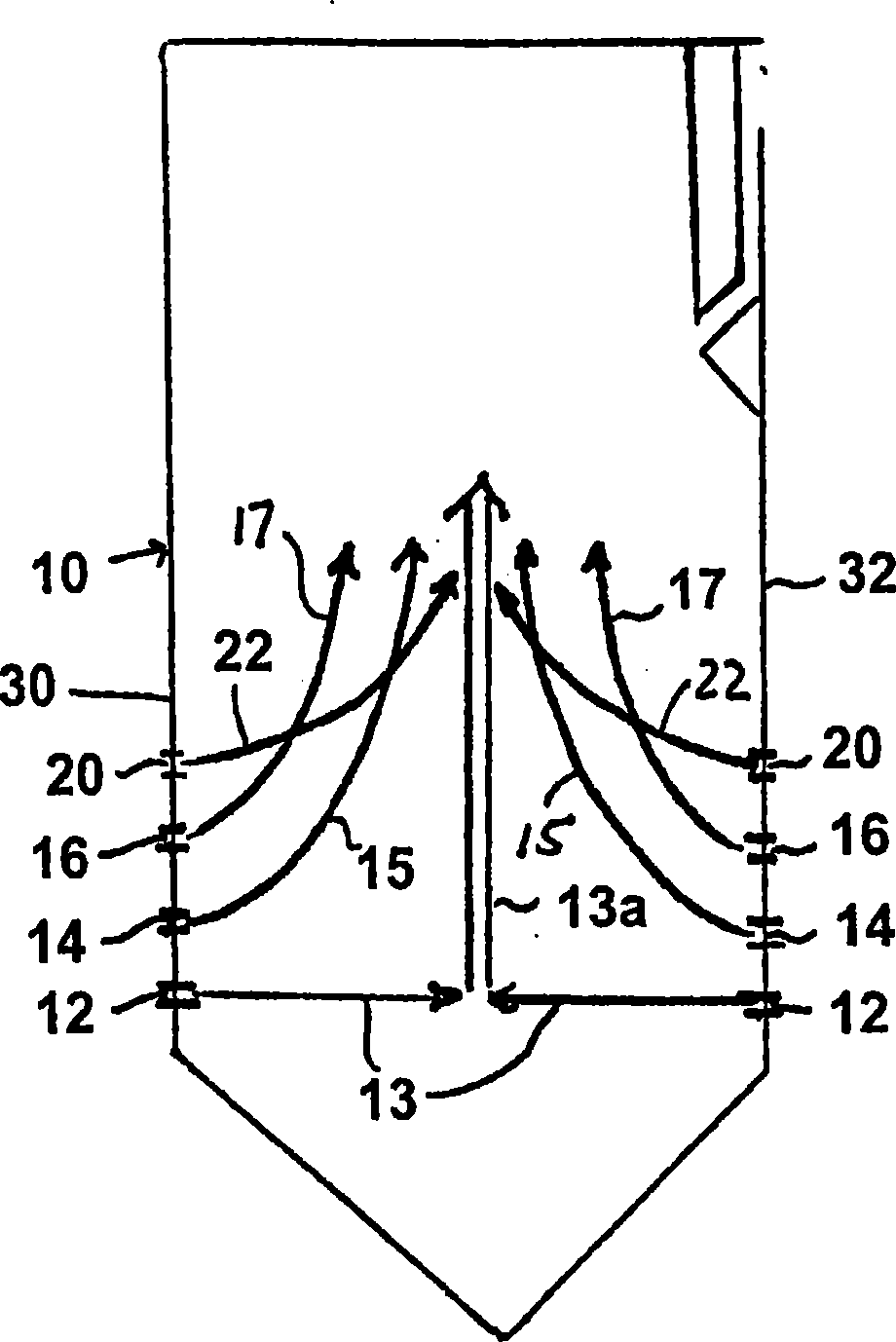

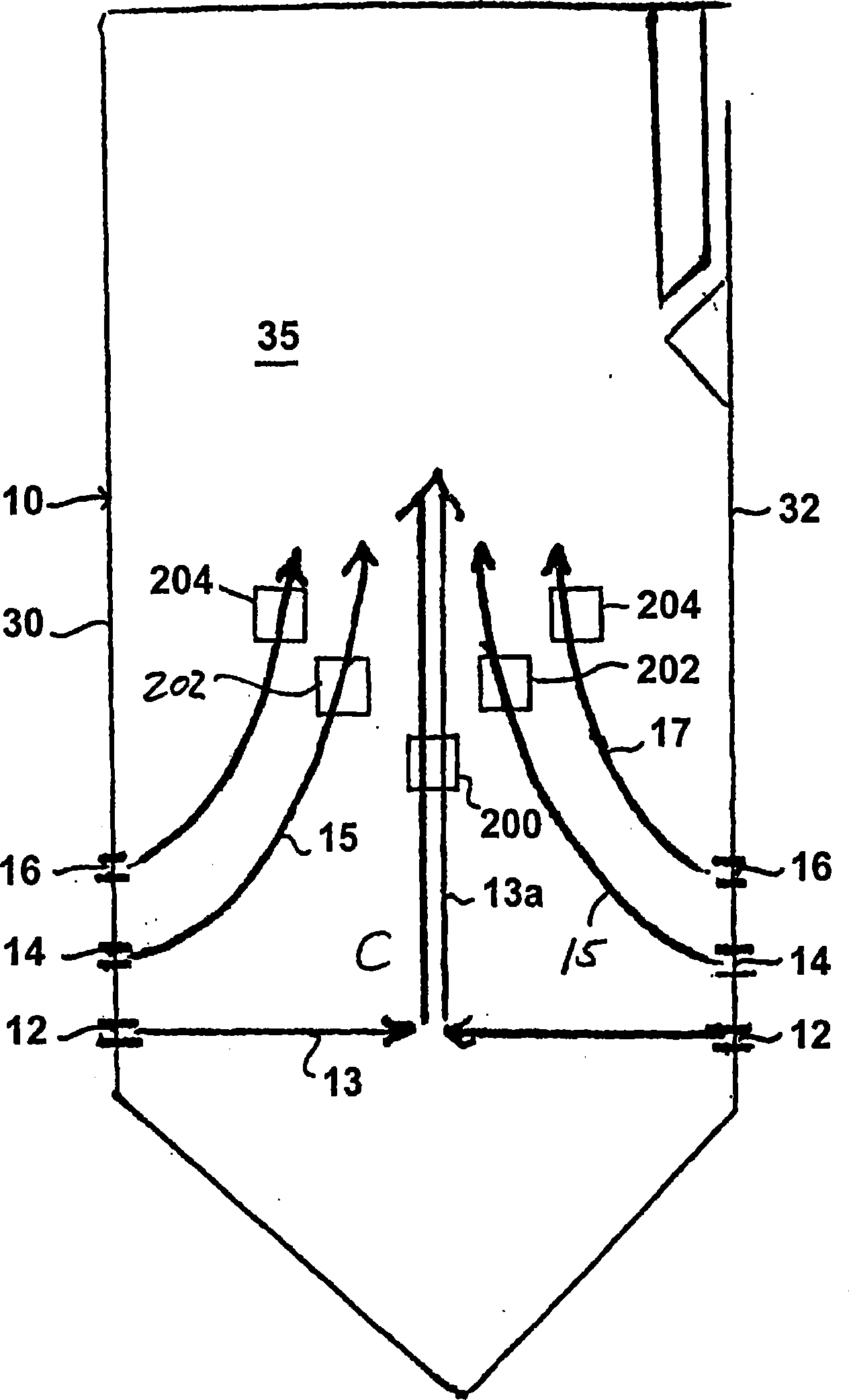

[0029] Referring now to the drawings, wherein like reference numerals are used throughout the seven figures to refer to identical or functionally similar elements, Figure 3-6 Each shows a cavity 10 of an opposed wall furnace comprising the OFA configuration of the present invention. and figure 1 and 2The oven cavity 10 is shown as in the Figure 3-6 In each of the drawings, three burner layers 12, 14, 16 are provided on the front and rear walls 30, 32, respectively. However, as those skilled in the art will appreciate, the present invention is applicable to single-wall and opposed-wall furnace cavities 10 having fewer or more burner layers.

[0030] image 3 Here, the superheated air ports 200 , 202 , 204 are located in the side walls 35 instead of the front or rear walls 30 , 32 . The OFA ports 200, 202, 204 are arranged such that the jet air may generally transversely intersect the flame passages 13a, 15, 17, respectively. That is, the lower OFA port 200 will inject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com