Heavy oil electro-desalting back-washing system and method thereof

A technology of backwashing and electric desalination, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. The effect of removing sand and silt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

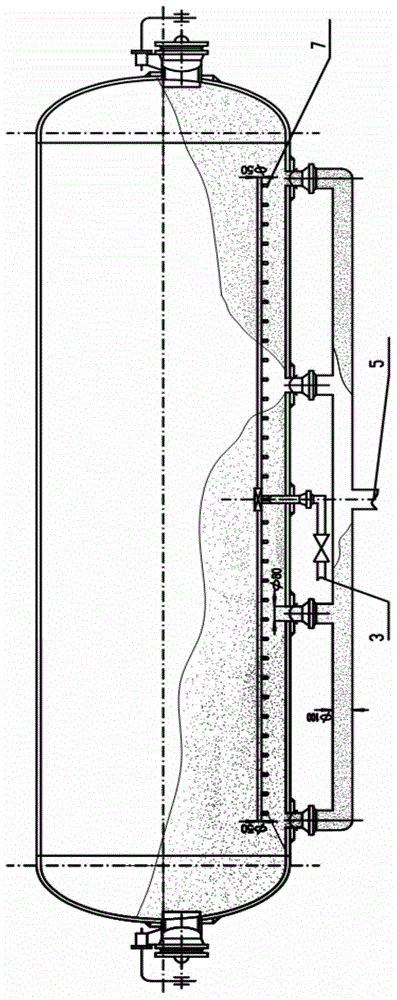

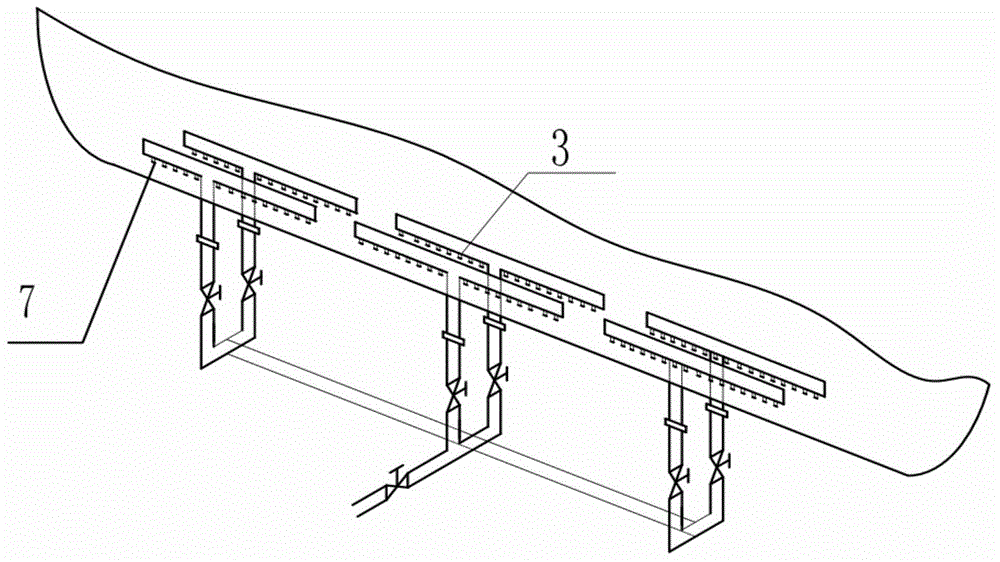

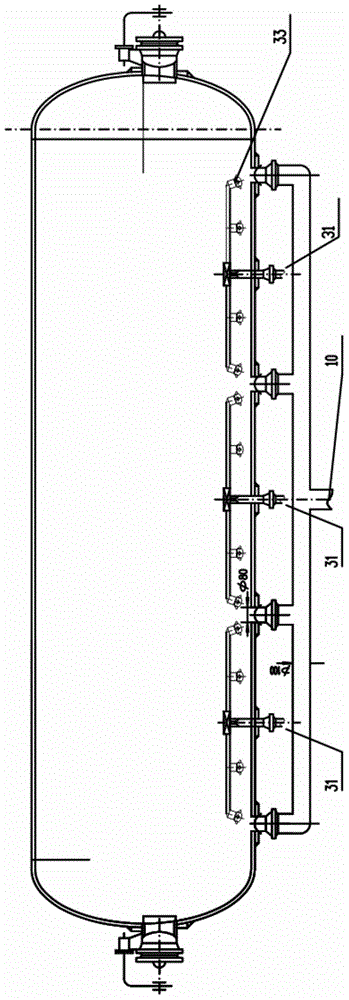

[0041] The invention provides a new electric desalination and backwashing system for inferior heavy oil. Under the premise of not changing the structure of the electric desalination tank and the production process, the power system matching the process of the electric desalination system is used, and the method of rotating forced injection is used. All the power carried by the liquid entering the tank directly acts on the areas where deposition may occur, and cleans the electric desalination tank in all directions. The device adopts omni-directional rotating nozzle technology for electric desalination backwashing operation, which can remove sediment and deposits in the electric desalination tank and optimize the residence time in the electric desalination tank.

[0042] combine image 3 , F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com