Module combined type photocatalyst pollutant disposal system

A technology of pollutant treatment and photocatalyst, which is applied in the field of modular combined photocatalyst pollutant treatment system, can solve the problems of not being able to meet the strong treatment of pollutants and weak treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

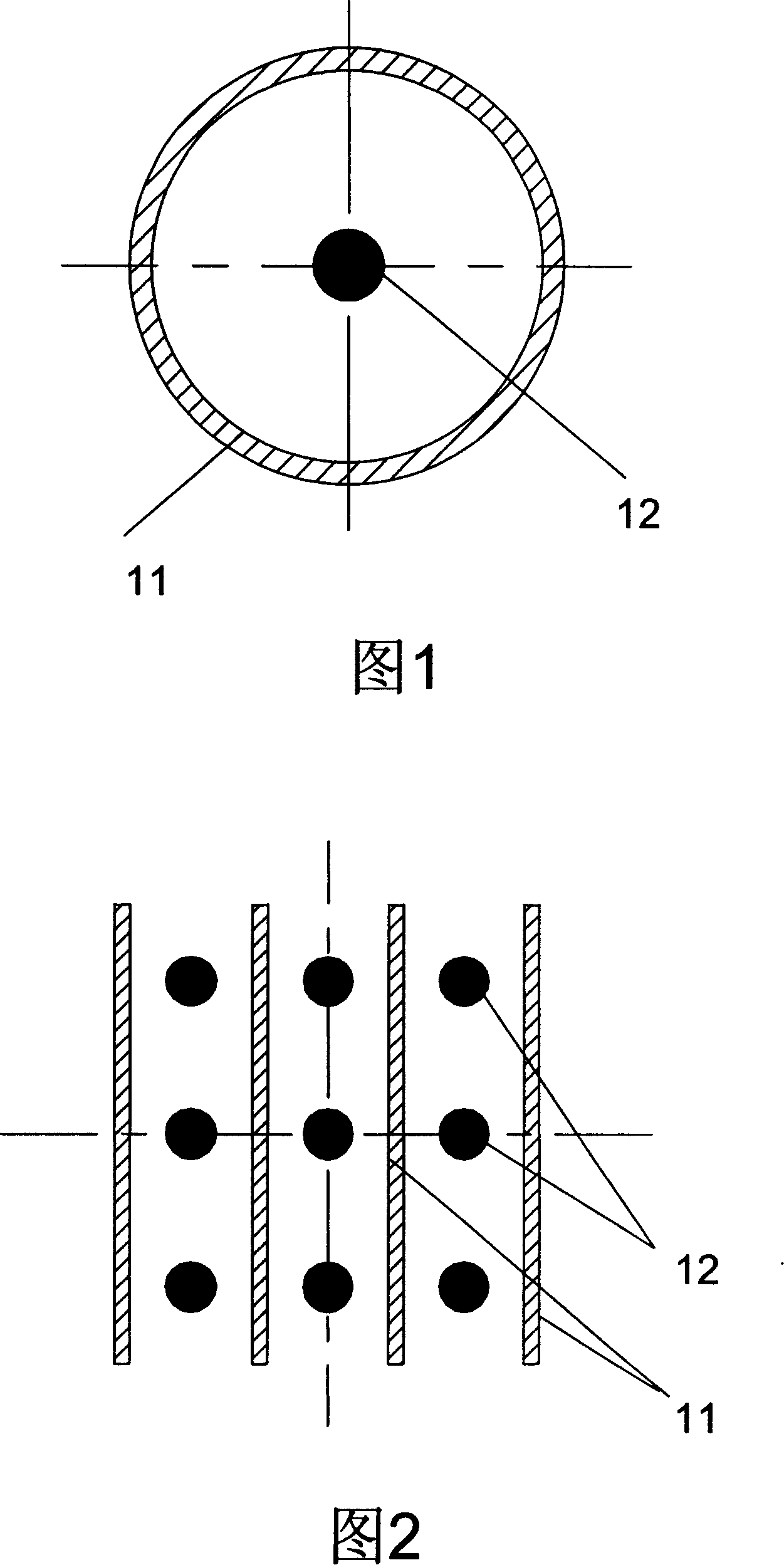

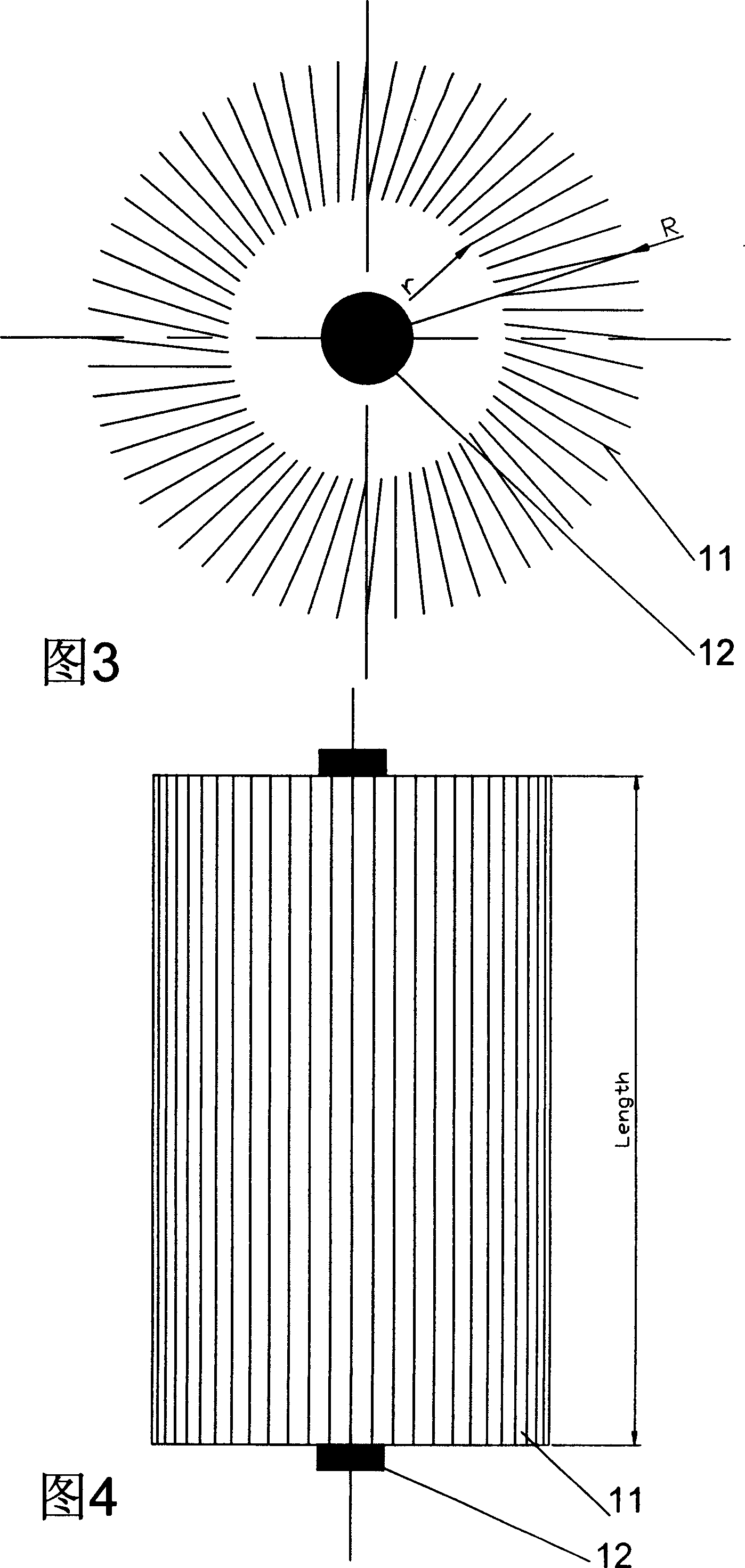

Embodiment 1

[0040]In the embodiment 1 shown in Fig. 9, photocatalyst carrier structure part 10 is designed as an independent treatment module, and a pollutant treatment system that two independent treatment modules are combined by parallel mode, the flow direction of pollutant fluid is as direction As shown in AB, the so-called parallel connection means that the flow direction of the pollutant fluid flows to two photocatalyst carrier structural components arranged side by side at the same time, in no particular order. The AB flow direction in this embodiment is perpendicular to the ultraviolet lamp tube 12. In FIG. 9, 11 is a photocatalyst carrier, 12 is an ultraviolet lamp tube, and 13 is a housing.

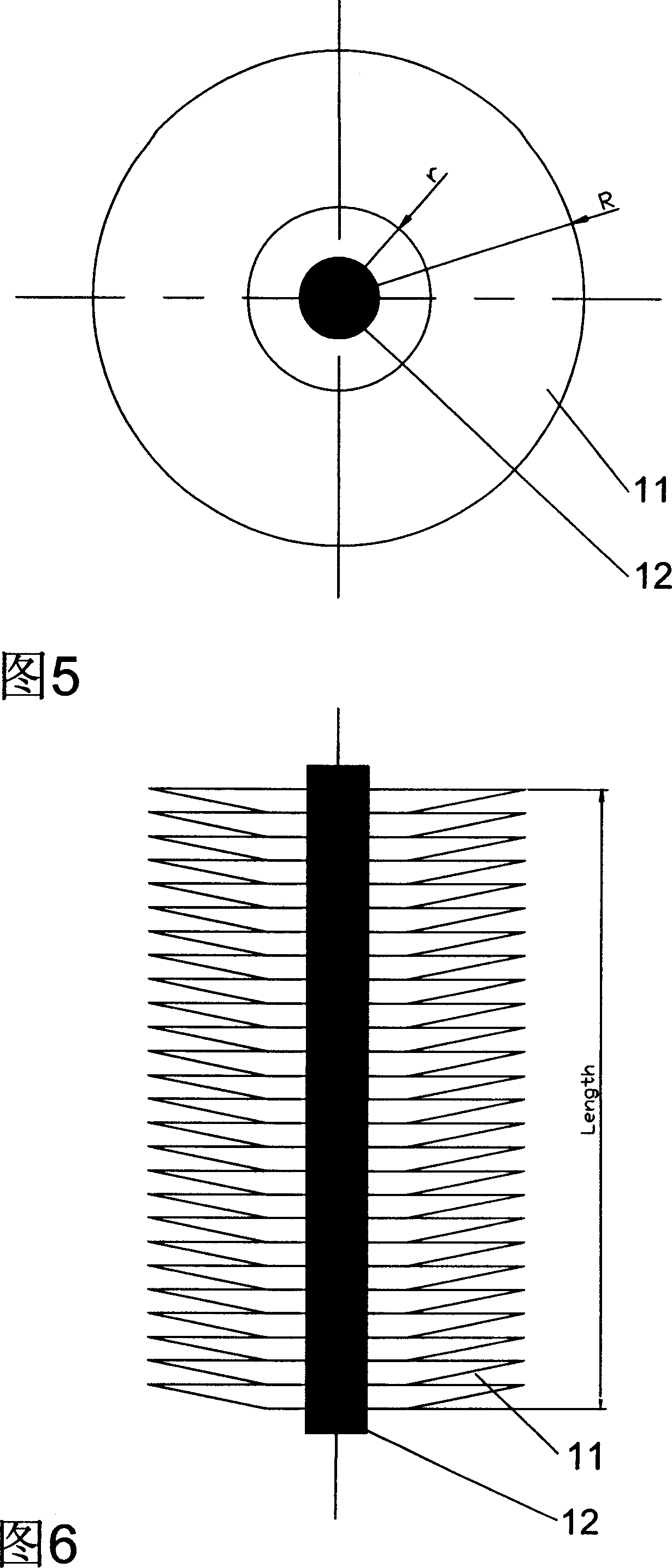

Embodiment 2

[0042] In the embodiment shown in Fig. 10, the photocatalyst carrier structure part 10 is designed as an independent treatment module, and a pollutant treatment system formed by combining two independent treatment modules in series, the flow direction of the pollutant fluid is as direction CD As shown, the so-called series mode, that is, the flow direction of the pollutant fluid flows to two photocatalyst carrier structural components arranged side by side. The flow direction of CD in this embodiment is perpendicular to the ultraviolet lamp tube 12; as shown in Figure 10, 11 is a photocatalyst carrier, 12 is an ultraviolet lamp tube, and 13 is a housing.

Embodiment 3

[0044] In the embodiment shown in Figure 11, as shown in Figure 11, in this example, photocatalyst carrier structure part 10 is designed as an independent processing module, and four independent processing modules are combined by not only parallel but also serial mode In a pollutant treatment system, the flow direction of the pollutant fluid is shown in the direction EF. The so-called series-parallel connection means that there are both series and parallel connections. The upper and lower processing modules are connected in series, and the left and right processing modules are considered to be connected in parallel. . In this embodiment, the flow direction of EF of the pollutant fluid is perpendicular to the ultraviolet lamp 12 . In Fig. 11, 11 is a photocatalyst carrier, 12 is an ultraviolet lamp tube, and 13 is a housing. Each photocatalyst carrier structural part 10 includes a number of photocatalyst carriers 11 and ultraviolet lamp tubes 12 , and the carrier 11 in the pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com