Method for manufacturing wear-resistant steel pipe by using hot-rolling coiled plate

A wear-resistant steel pipe and hot-rolled coil technology, applied in the field of metallurgical manufacturing, can solve the problems of high energy consumption, long manufacturing cycle, low qualification rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066]According to the present invention, the mass percentages of the chemical elements are: C: 0.15%, Si: 0.20%, Mn: 1.45%, Ni: 0.16%, Cr: 0.18%, Mo: 0.16%, Cu: 0.25%, Nb: 0.010% , V: 0.005%, Ti: 0.019%, Al: 0.034%, B: 0.0013%, P: 0.012%, S: 0.003%, N: 0.0042%, and the rest is iron wear-resistant steel pipe, the heat treatment method described The steps are: use ERW steel pipe unit to manufacture ERW steel pipe, use induction heating equipment to inductively heat the ERW steel pipe, and then heat the ERW steel pipe to 930°C within 100s; then quench with water at a cooling rate of 22°C / s, and quench The latter ERW steel pipe is heated to 260°C with induction heating equipment, and the tempering time is 120s to obtain a wear-resistant steel pipe with mechanical properties: HBW400.

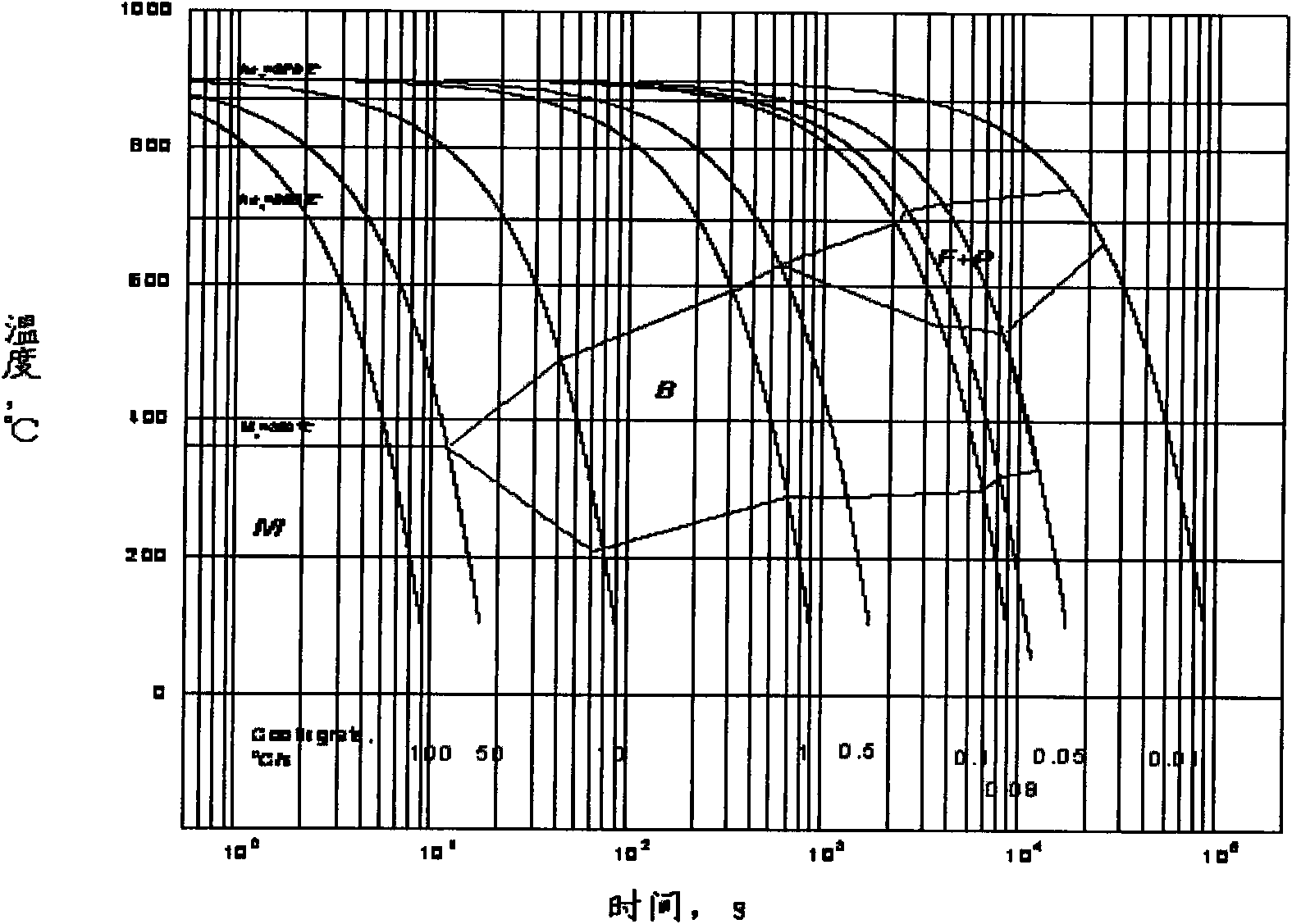

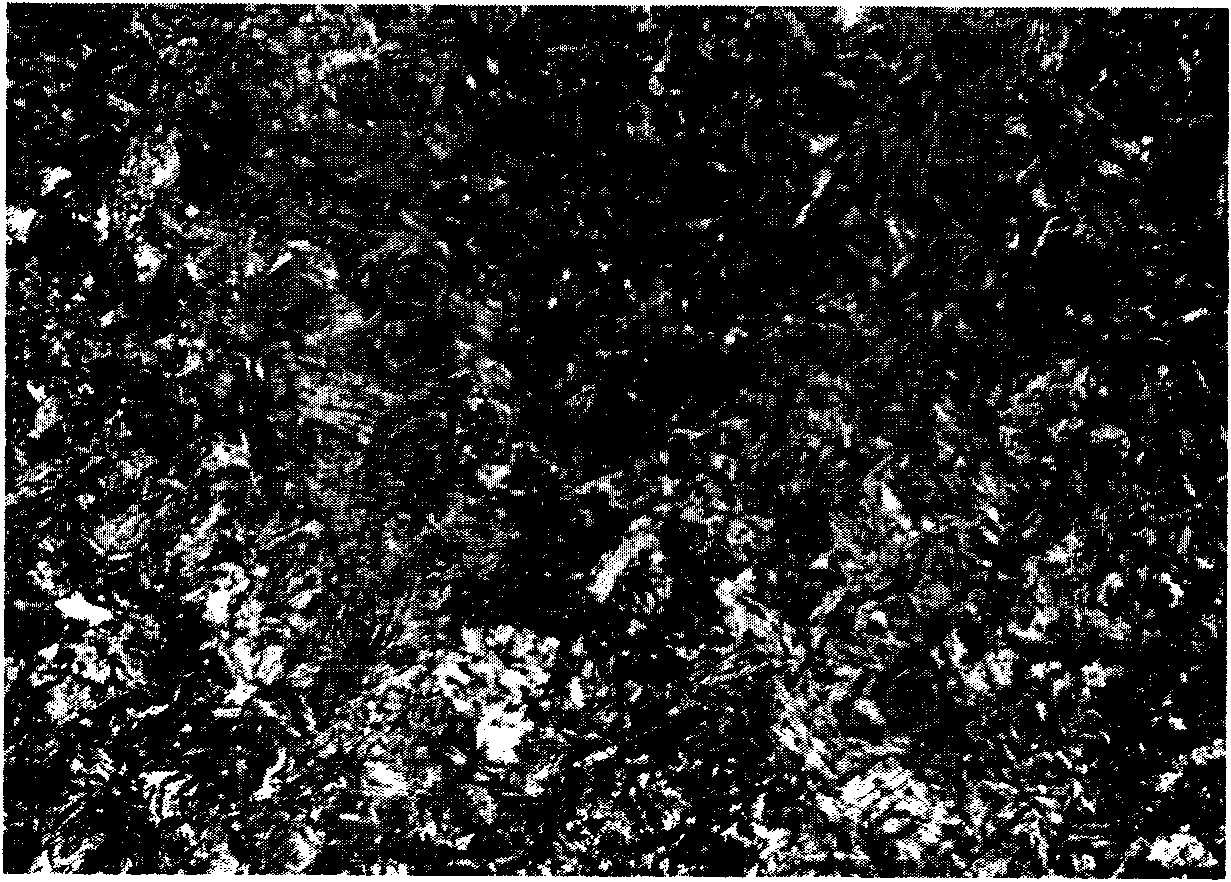

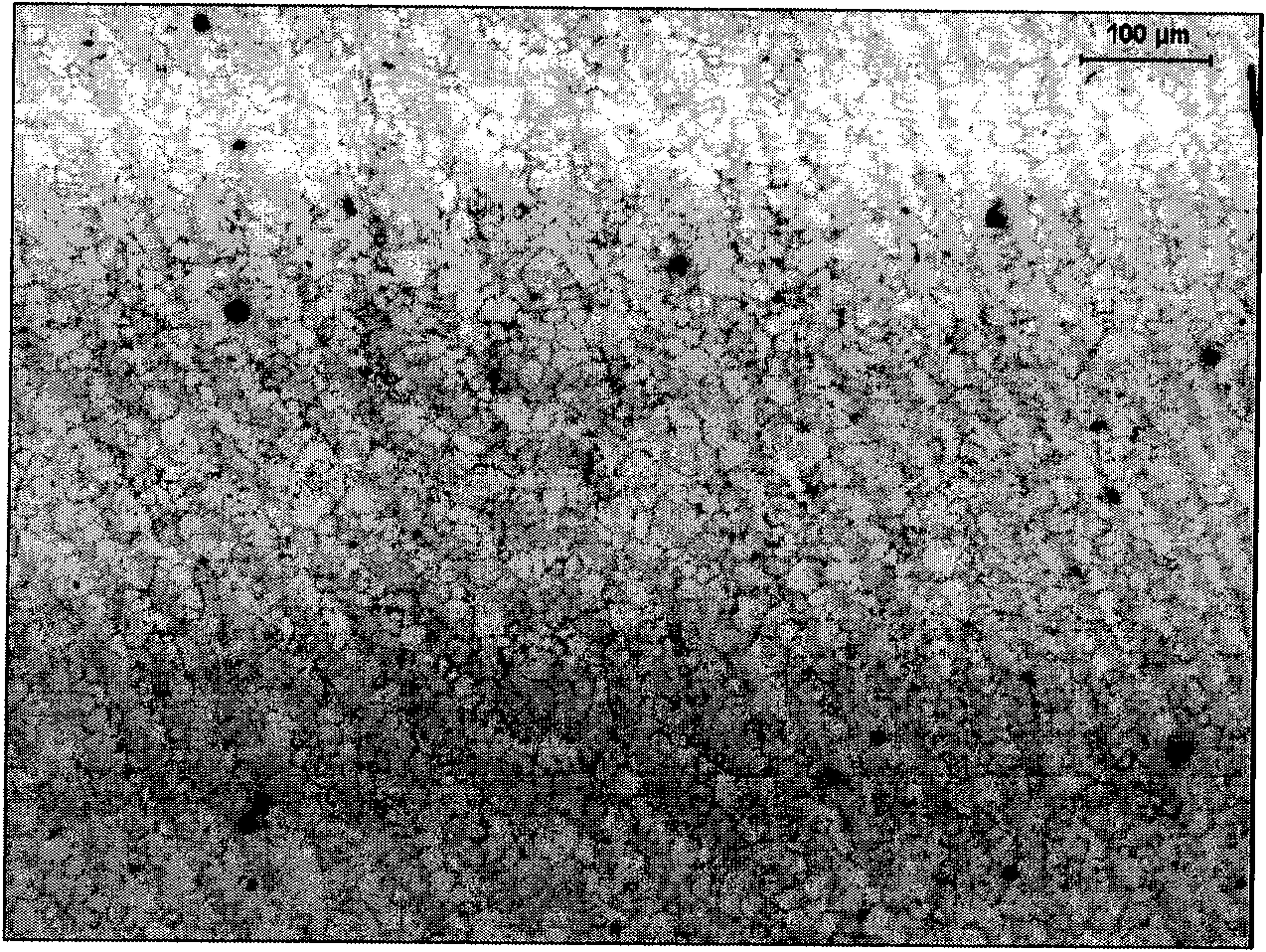

[0067] figure 1 Shows the TTT curve diagram of the HBW400 wear-resistant steel pipe made of hot-rolled coils using the Formantor-F thermal dilatometer, combined with the observation of the metallograp...

Embodiment 2

[0069] When the mass percentage of each chemical element in the manufacturing is: C: 0.10-0.18%, Si: 0.15-0.50%, Mn: 0.70-1.40%, Ni: 0.01-0.20%, Cr: 0.10-0.30%, Mo: 0.10-0.55% , Cu: 0-0.20%, Nb: 0-0.035%, V: 0-0.035%, Ti: 0-0.020%, Al: 0.010-0.060%, B: 0.0005-0.0040%, Zr: 0-0.0005, P When <0.020%, S<0.010%, N<0.0080%, and the rest is iron wear-resistant steel pipe, the heat treatment method steps are: heating to 930-960℃ in induction heating equipment for austenitizing, and the heating time is 60-140s, heating and quenching cooling rate ≥10℃ / S, heating to 280-320℃ in induction heating equipment for tempering, tempering time 80-180s, to obtain tempered martensite structure. Then carry out straightening, flaw detection, surface inspection, sampling inspection, and obtain the wear-resistant steel pipe with mechanical properties: HBW360.

Embodiment 3

[0071] When the mass percentage of each chemical element in the manufacturing is: C: 0.10-0.18%, Si: 0.15-0.50%, Mn: 0.70-1.40%, Ni: 0.01-0.30%, Cr: 0.10-0.30%, Mo: 0.10-0.55% , Cu: 0-0.25%, Nb: 0-0.040%, V: 0-0.040%, Ti: 0-0.020%, Al: 0.010-0.075%, B: 0.0005-0.0040%, Zr: 0-0.0005%, When P<0.020%, S<0.010%, N<0.0080%, and the rest are iron wear-resistant steel pipes, the heat treatment method steps are: heating to 930℃-960℃ in induction heating equipment for austenitizing, heating The time is 60-140s, and then the ERW steel pipe is quenched in a water-cooled or aerosol-cooled quenching unit at a quenching cooling rate of ≥10℃ / S to obtain a steel pipe with a quenched martensitic structure, and then heated to 260℃ with induction heating equipment- Tempering at 300°C, the tempering time is 60-180s, the quenched martensite is transformed into tempered martensite, and then straightening, flaw detection, surface inspection, sampling inspection are performed to obtain a wear-resistant st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com