Method for preparing lithium ion battery positive electrode material lithium vanadium oxide LiV3O8

A lithium vanadium oxide, lithium ion battery technology, applied in vanadium compounds, battery electrodes, chemical instruments and methods, etc., can solve the problem that it is difficult to achieve the level of molecular contact in liquid phase, the electrochemical performance is not very ideal, and the reaction In order to improve the pulping performance, improve the effective contact and shorten the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

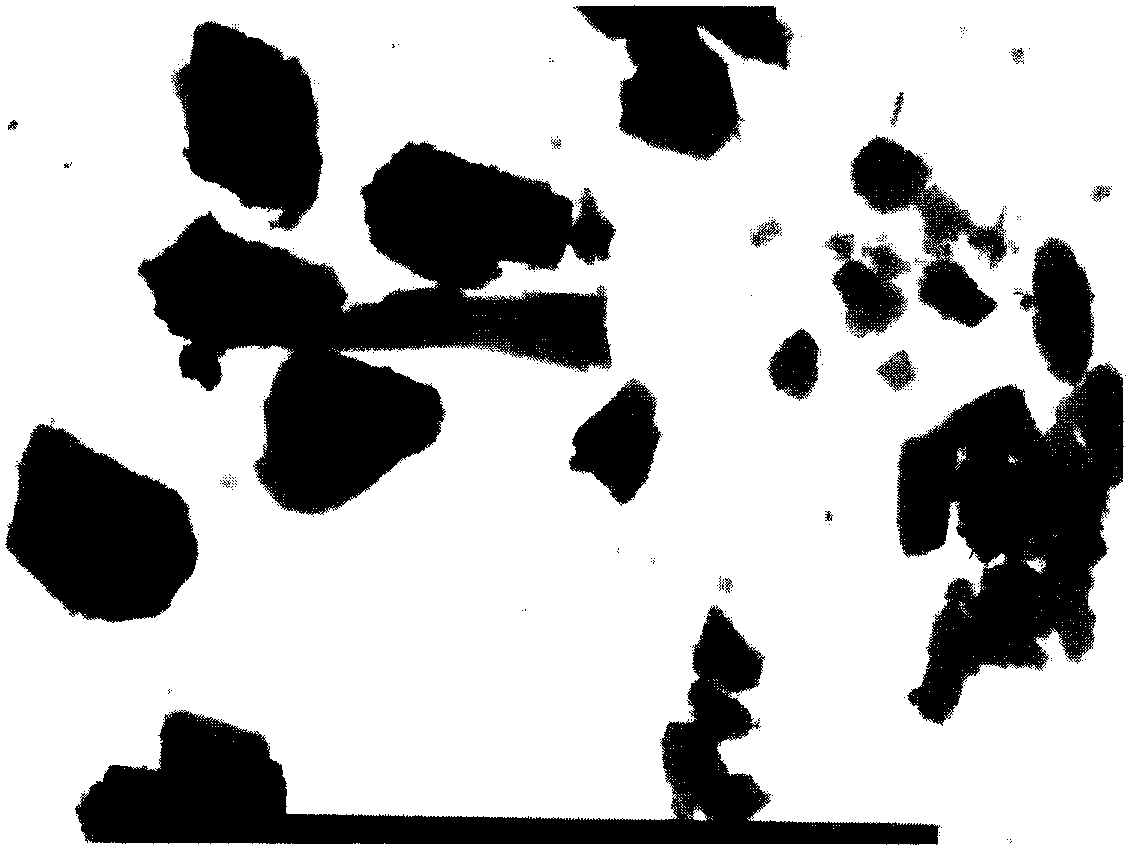

Image

Examples

Embodiment Construction

[0014] The object of the present invention is to provide a submicron lithium-ion battery cathode material lithium vanadium oxide LiV with simple process, suitable for batch production, good product uniformity and low preparation temperature 3 o 8 method of preparation.

[0015] In order to achieve the above object, the technical scheme of the present invention is: a kind of preparation lithium ion battery material lithium vanadium oxide LiV 3 o 8 The method is completed by the following two steps:

[0016] (1) lithium carbonate, vanadium pentoxide and citric acid monohydrate (molecular formula is C 6 h 8 o 7 ·H 2 O) Weigh and mix evenly according to the amount ratio of substances 1:3:4, and ball mill in a ball mill for 10min to 200min at room temperature (20±5°C), take it out and place it in a muffle furnace under an air atmosphere at 80°C for 1 hours, then heated to 350°C for sintering for 5 hours, cooled and pulverized to form a mixture.

[0017] (2) The mixture prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com