A method for enhancing the performance of waste paper pulp-based paper by using formaldehyde hemicellulose

A technology for hemicellulose and waste paper pulp, applied in the field of papermaking, can solve the problems of immature use methods, and achieve the effects of improving quality and efficiency, increasing output, and widening sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method of using hydroformylated hemicellulose to enhance the performance of waste paper pulp-based paper in this embodiment, the specific steps are as follows:

[0022] (1) Add 20mL of water, 0.66g of hemicellulose, 5% (w / v) sodium hydroxide in a 100mL round bottom flask, stir at 60°C for 0.5h; then add 0.1M hydrochloric acid to adjust the pH of the solution to 3 , adding glyoxal of 1, 2, 3, 4, and 5 times the mass of hemicellulose respectively, and reacting at 80°C for 4 hours to obtain hydroformylated hemicellulose.

[0023] (2) Mixing 1.2 g of waste paper pulp with an absolute dry weight and 0.012 g of the hydroformylated hemicellulose obtained in step (1), adding water to decompose, making paper, drying, and obtaining reinforced paper.

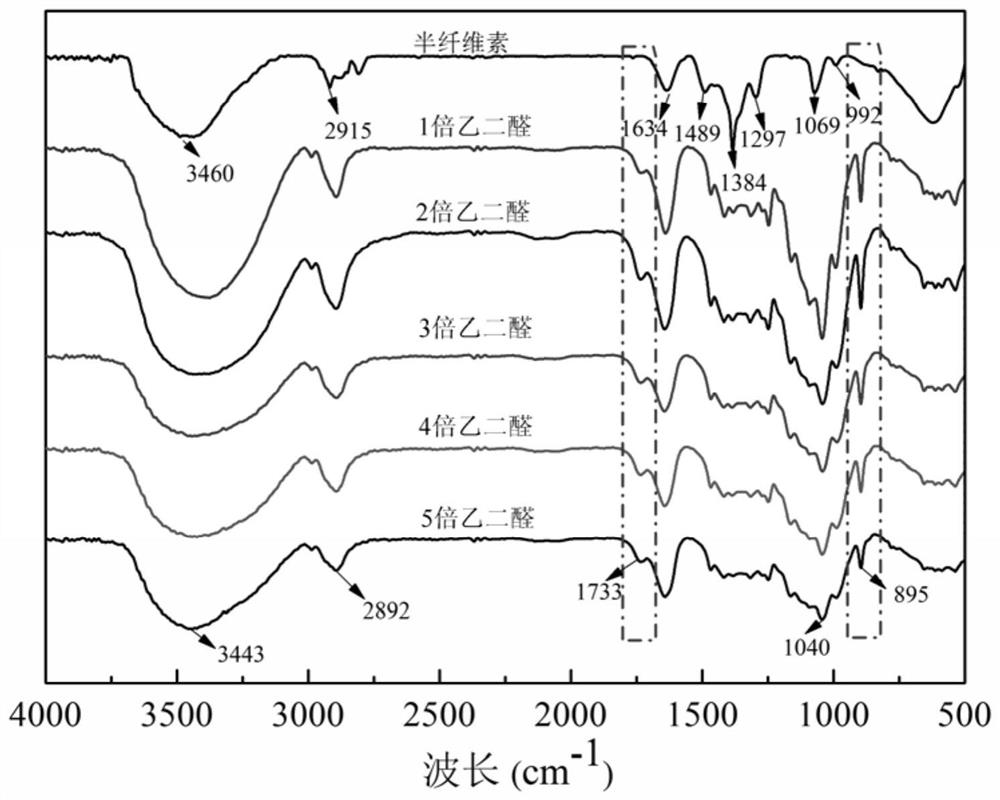

[0024] The infrared spectrograms of the hemicellulose of the present embodiment and the hemicellulose modified after adding different amounts of glyoxal are as follows: figure 1 shown. from figure 1 It can be seen that 3460cm ...

Embodiment 2

[0026] A method of using hydroformylated hemicellulose to enhance the performance of waste paper pulp-based paper in this embodiment, the specific steps are as follows:

[0027] (1) Add 20mL of water, 0.66g of hemicellulose, 5% (w / v) sodium hydroxide into a 100mL round bottom flask, stir at 60°C for 0.5h; then add acid to adjust the pH of the solution to 3, add 0.69mL of glyoxal was reacted at 80°C for 4h to obtain the hydroformylated hemicellulose.

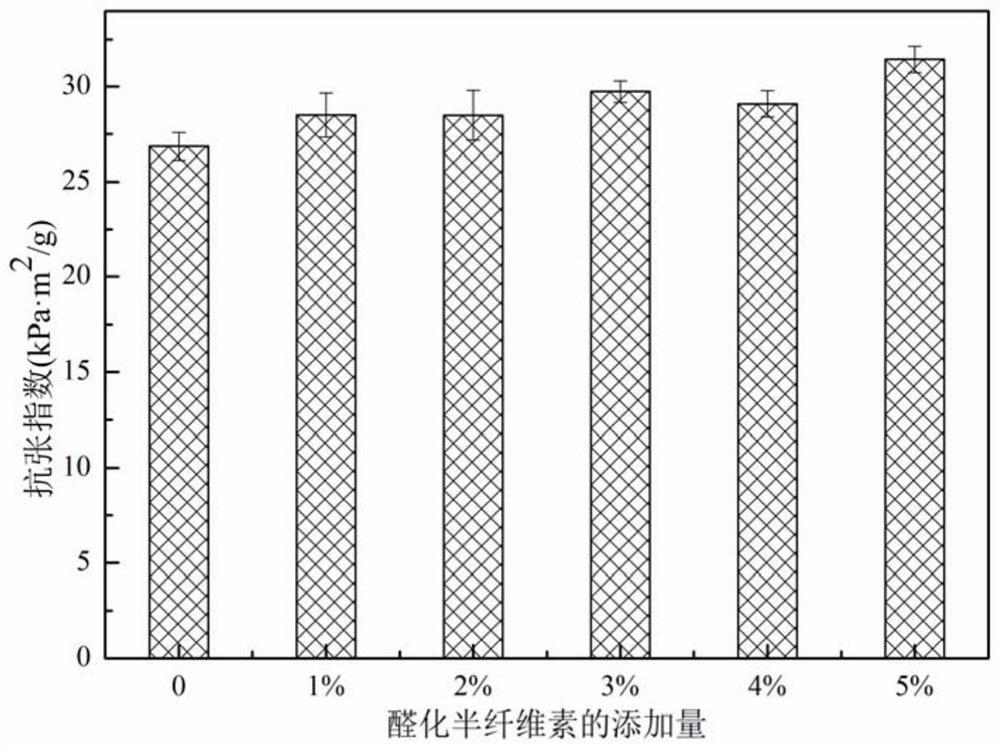

[0028] (2) The waste paper pulp that the absolute dry mass is 1.2g is mixed with the obtained hydroformylated hemicellulose of step (1), so that the addition of the hydroformylated hemicellulose is 0%, 1%, and 2% of the dry mass of the waste paper pulp respectively. %, 3%, 4% and 5%, add water to decompose, make paper, dry, and get strengthened paper.

[0029] In this example, in the case of different addition amounts of hydroformylated hemicellulose, the comparison chart of the tensile properties of the obtained paper is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com