Time control heating method and circuit thereof

A heating circuit and heating method technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of fixed preheating time length, overflowing pot, slurry boiling, etc., to achieve the effect of optimizing pulping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

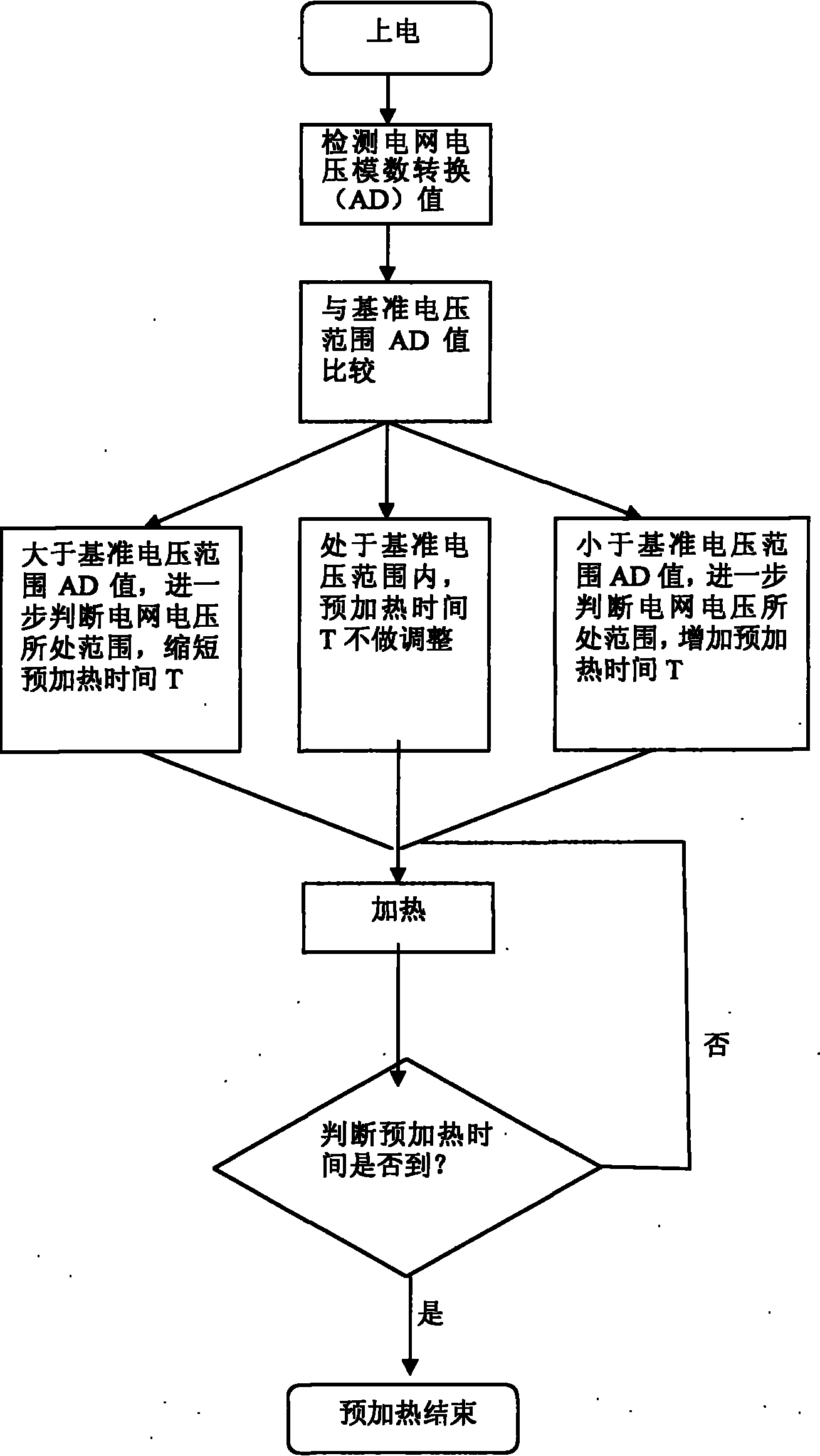

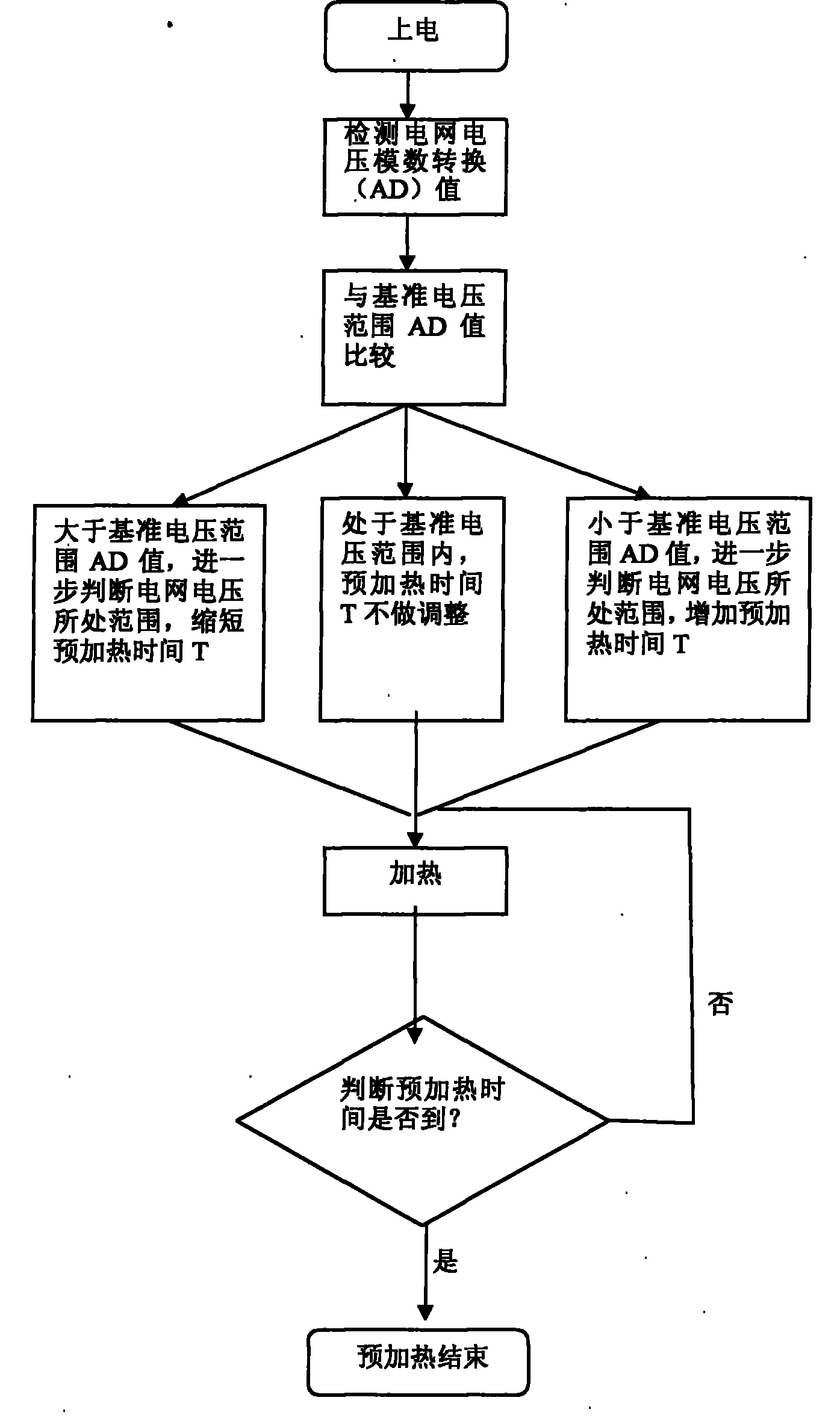

[0021] First, explain the idea and key of the present invention:

[0022] The grid voltage is detected by the voltage detection unit circuit, and different heating on-times are adjusted by software algorithms according to different grid voltages. Compared with other time-controlled heating circuits, the key of the present invention is the voltage detection unit and the single-chip control process.

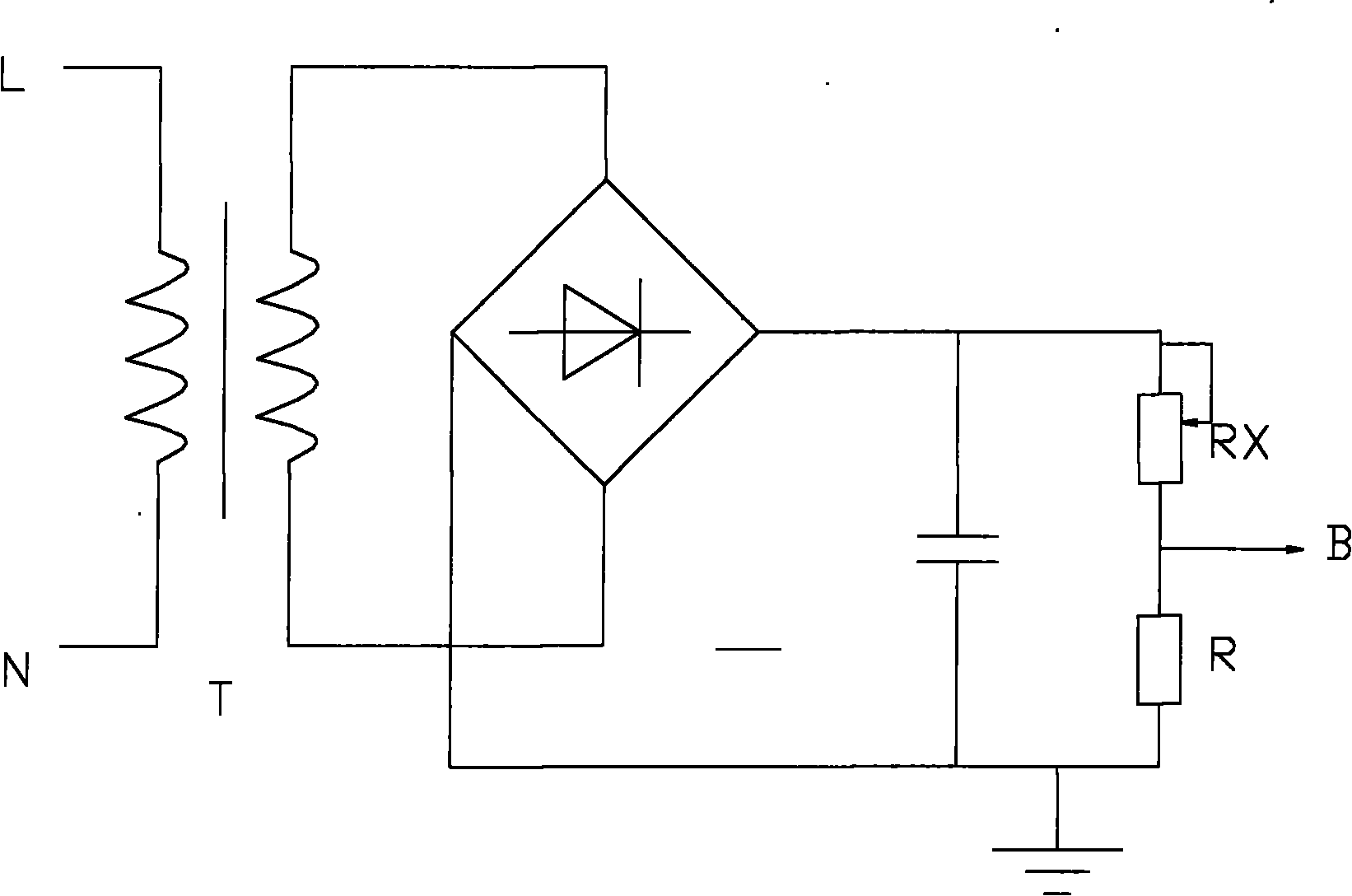

[0023] Such as figure 1 As shown, the time-controlled heating circuit of the specific embodiment of the present invention is applied to the preheating of the soybean milk machine, and the voltage detection unit is: the mains electricity passes through the live line L and the neutral line N through the transformer T, and then full bridge rectification and filtering to obtain a relatively smooth DC level, The direct current passes through the variable resistor RX and the voltage divider resistor R to obtain the relative working voltage of the whole machine at the voltage sampling point B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com