Control method of food processing machine

A food processing machine and control method technology, applied in computer control, program control, general control system, etc., can solve the problems of silicon controlled rectifier power instability, failure to meet actual needs, and inability to achieve low power, so as to maintain thermal inertia Stable, solve the delay of zero-crossing signal detection, and avoid the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

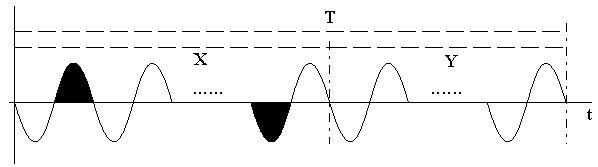

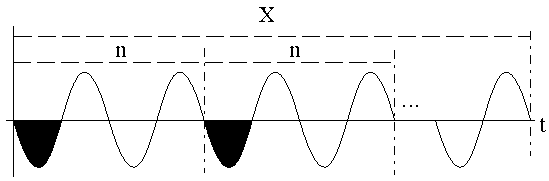

[0027] The present invention is a control method of a food processing machine. The food processing machine includes a control device and a load. The control device controls the work of the load through a silicon controlled rectifier. The rated power of the load is P0. It is characterized in that the The control device obtains the load power P by periodically controlling the thyristor, and includes a power generation unit and a power adjustment unit in a control period T, the period of the power generation unit is X, and the power adjustment unit The period of is Y, the power generated by the power generation unit is P1, P=(X / (X+Y))*P1, and the periods X and Y are integer multiples of the half-wave period respectively.

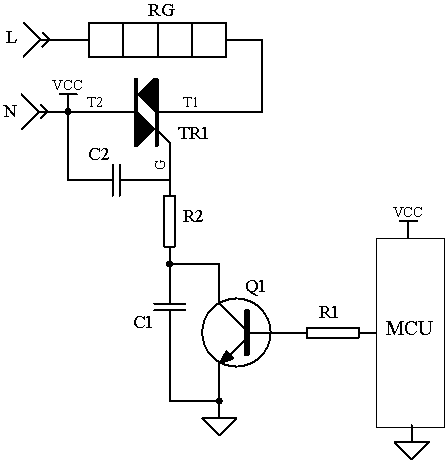

[0028] Such as figure 1 As shown, the heating circuit of a food processor is taken as an example. In this embodiment, the load includes a heating device RG, and the control device includes a main control chip MCU. The main control chip MCU controls and triggers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com