Fan motor blade made of different aluminium casting alloys

A technology of casting aluminum alloy and wind turbines, which is applied in the direction of wind turbines, wind power generation, wind turbines, etc., which is consistent with the wind direction, and can solve problems such as poor electrical conductivity, affecting the performance of blades, and restrictions on the development of ultra-large wind turbine blades. Reach the requirements of reducing the minimum wind speed, increase the annual power generation time, and increase the effect of investment output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

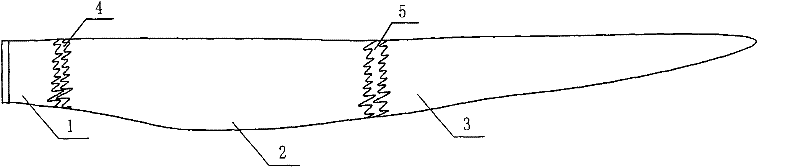

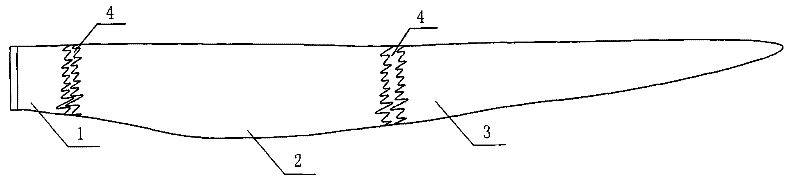

[0010] Such as figure 1 As shown, the blade of the present invention is divided into three parts: blade root 1, blade belly 2, and blade tip 3. Blade root 1 adopts aluminum-copper alloy, blade belly 2 adopts aluminum-silicon alloy, blade tip 3 adopts aluminum-magnesium alloy, blade root 1 and blade A first fusion zone 4 of aluminum-copper alloy and aluminum-silicon alloy is formed between the belly 2, and a second fusion zone 5 of aluminum-silicon alloy and aluminum-magnesium alloy is formed between the belly 2 and the blade tip 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com