Bean milk machine spliced with thin walled tube

A technology of thin-walled tubes and soybean milk machines, applied in beverage preparation devices, milk substitutes, household appliances, etc., can solve the problems of difficult cleaning of soybean milk stains, achieve the effect of improving the crushing effect, easy cleaning, and enhancing the effect of crushed soybean pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

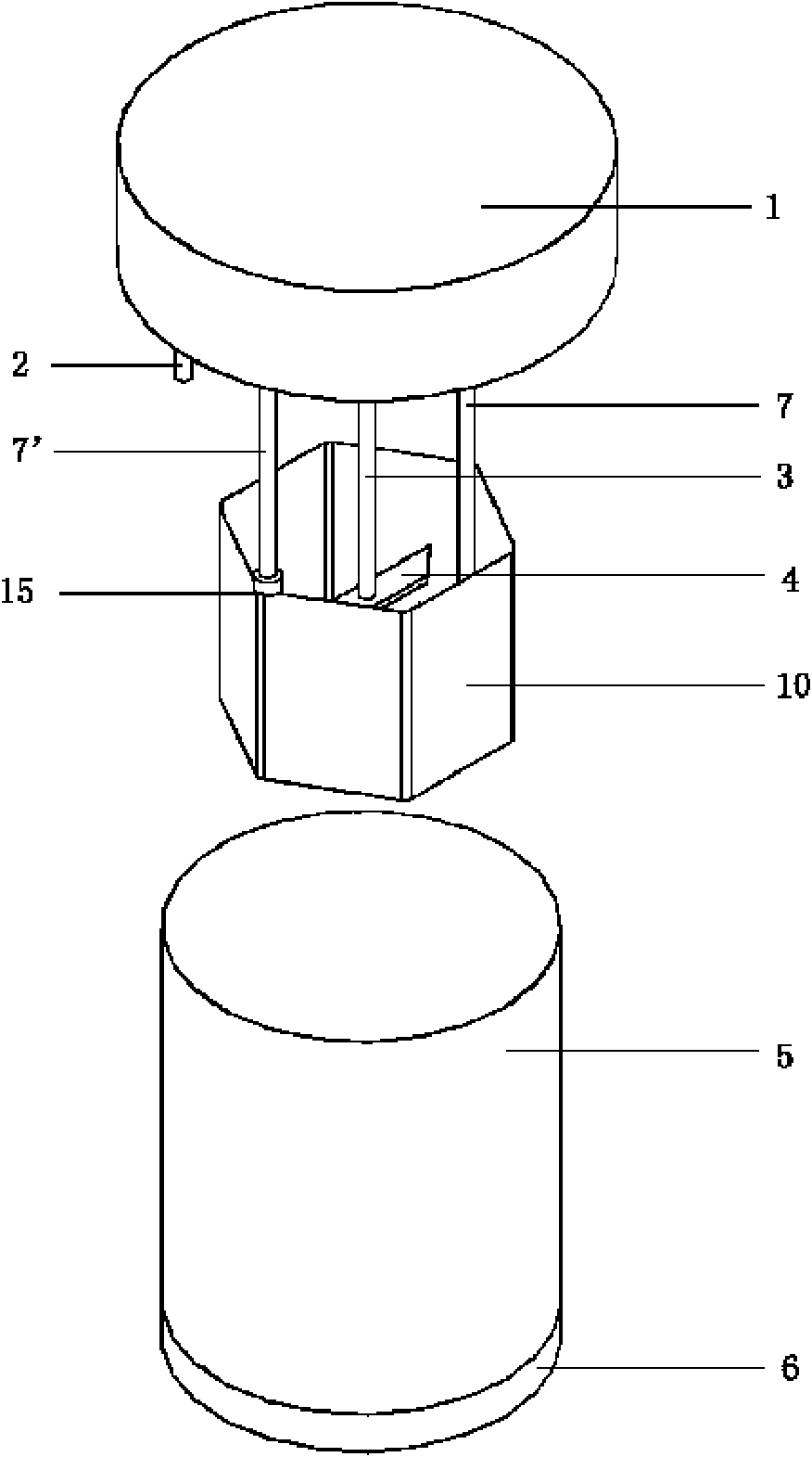

[0041] figure 1 is an embodiment of the present invention.

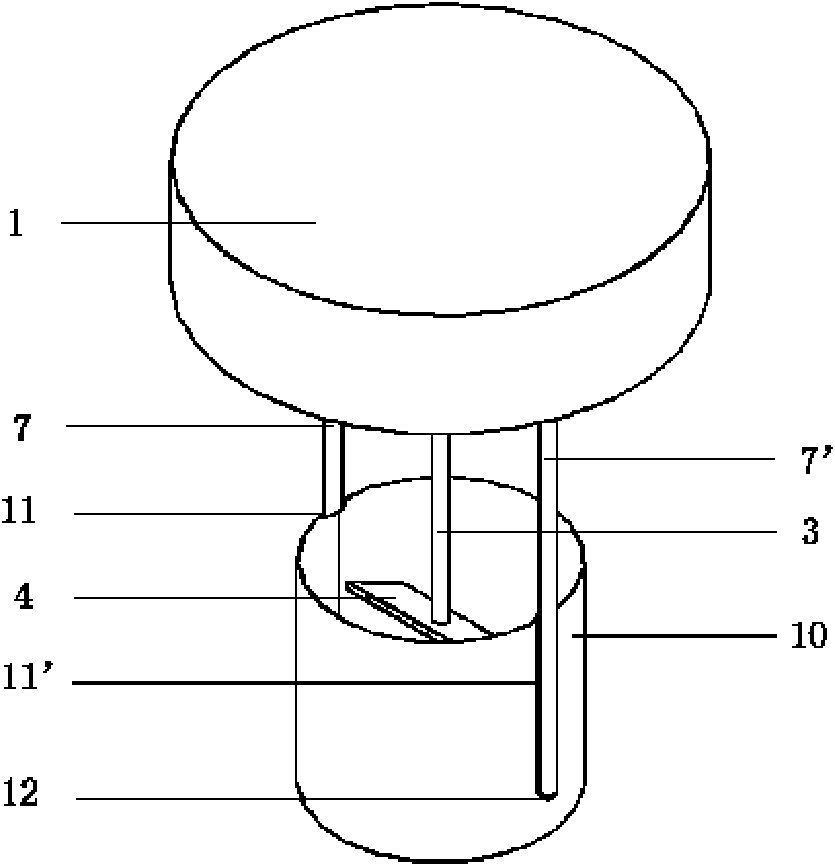

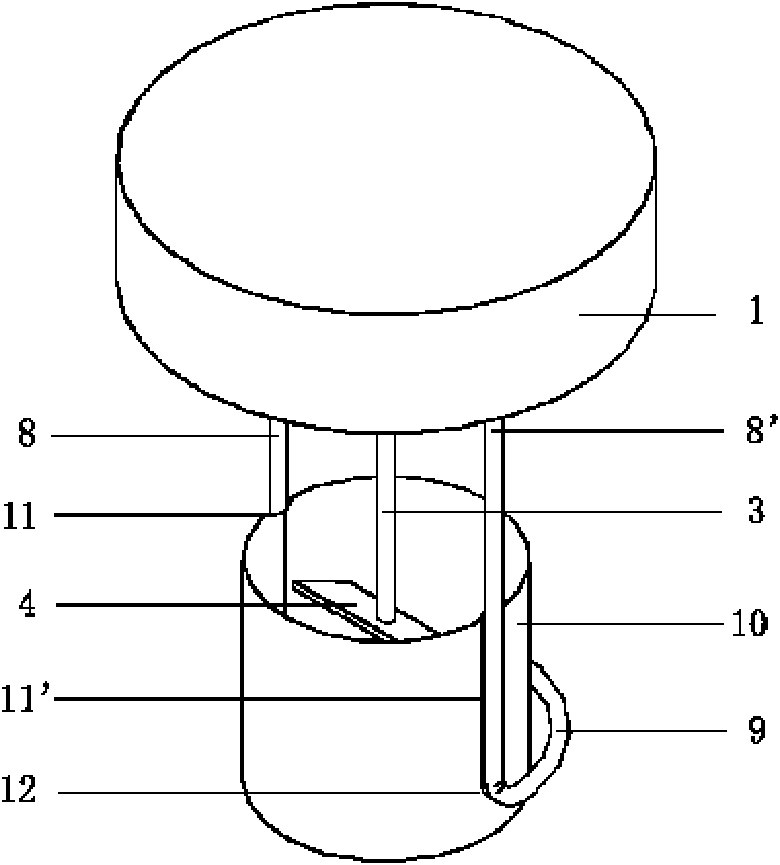

[0042] As an embodiment of the present invention, the soymilk machine for inserting thin-walled tubes involved in the present invention includes a container (5) for containing liquid, a heater (6) is arranged at the bottom of the container (5), and a heater (6) is placed in the container ( 5) The machine head (1) on the top, the liquid level detection electrode (2) is fixed under the machine head (1), the operation control component and the motor are built in the machine head (1), the motor drives the cutter shaft (3), the cutter shaft ( 3) Stretch downwards into the container (5), the cutter shaft (3) is fixed with a crushing cutter (4), and the lower part of the machine head (1) is also fixed with 2 hard rods ( 7) and (7'), the hard rod (7') has a shoulder (15), the hard rod (7) is provided with a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com