a food processor

A technology for food processors and heating devices, which can be used in kitchen utensils, household utensils, beverage preparation devices, etc., and can solve problems such as slurry paste, difficulty in ensuring taste, and power reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

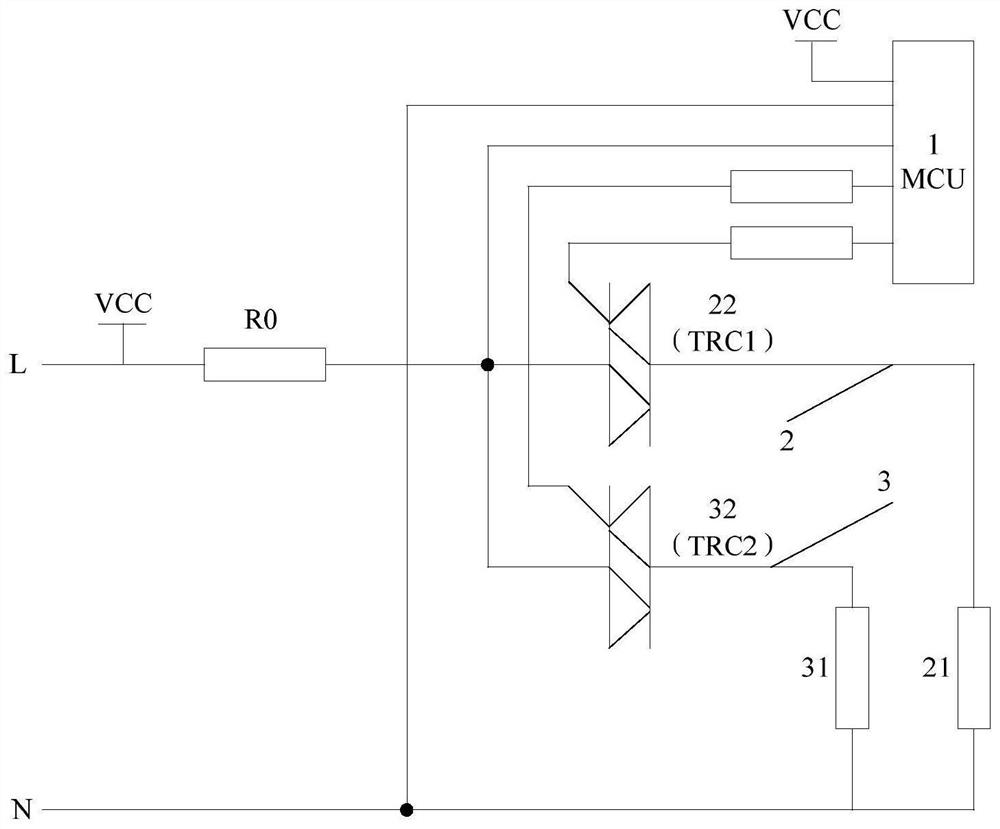

[0047] A food processor such as figure 1 As shown, the food processor includes: a main control unit (MCU) 1 and a first heating circuit 2; the first heating circuit 1 includes: a first heating device 21 connected in series with a power supply and a sampling resistor R0; the main control unit 1 passes the sampling The resistor R0 samples the current value and voltage value during the working period of the first heating device 21, and the food processor further includes: a second heating device 31, which is a positive temperature coefficient PTC heating device;

[0048] The main control unit 1 is also used to collect the current value and voltage value during the heating period of the second heating device 31 through the sampling resistor R0, and obtain the cup body temperature at the position of the second heating device 31 according to the collected current value and voltage value, and according to The obtained cup body temperature is used to detect the slurry state and / or adj...

Embodiment 2

[0062] This embodiment further optimizes the temperature detection method on the basis of the first embodiment. Optionally, the main control unit 1 collecting the current value and voltage value during the heating period of the second heating device 31 may include:

[0063] Control the disconnection of the first heating circuit, and control the conduction of the second heating circuit;

[0064] After the second heating loop is turned on for the first time period, collect the current value and voltage value during the heating period of the second heating device, and calculate the average value of the collected current value and the average value of the collected voltage value within the preset second time period ;

[0065] The detection of the temperature of the cup body at the location of the second heating device by the main control unit according to the collected current value and voltage value also includes:

[0066] The current average impedance of the second heating dev...

Embodiment 3

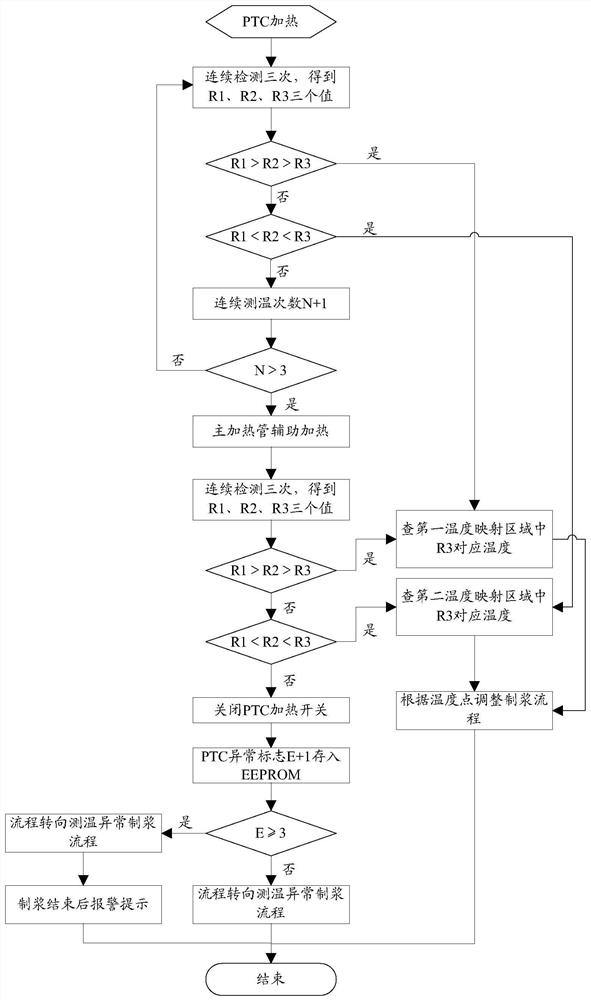

[0070] This embodiment further optimizes the PTC temperature measurement algorithm on the basis of the first or second embodiment.

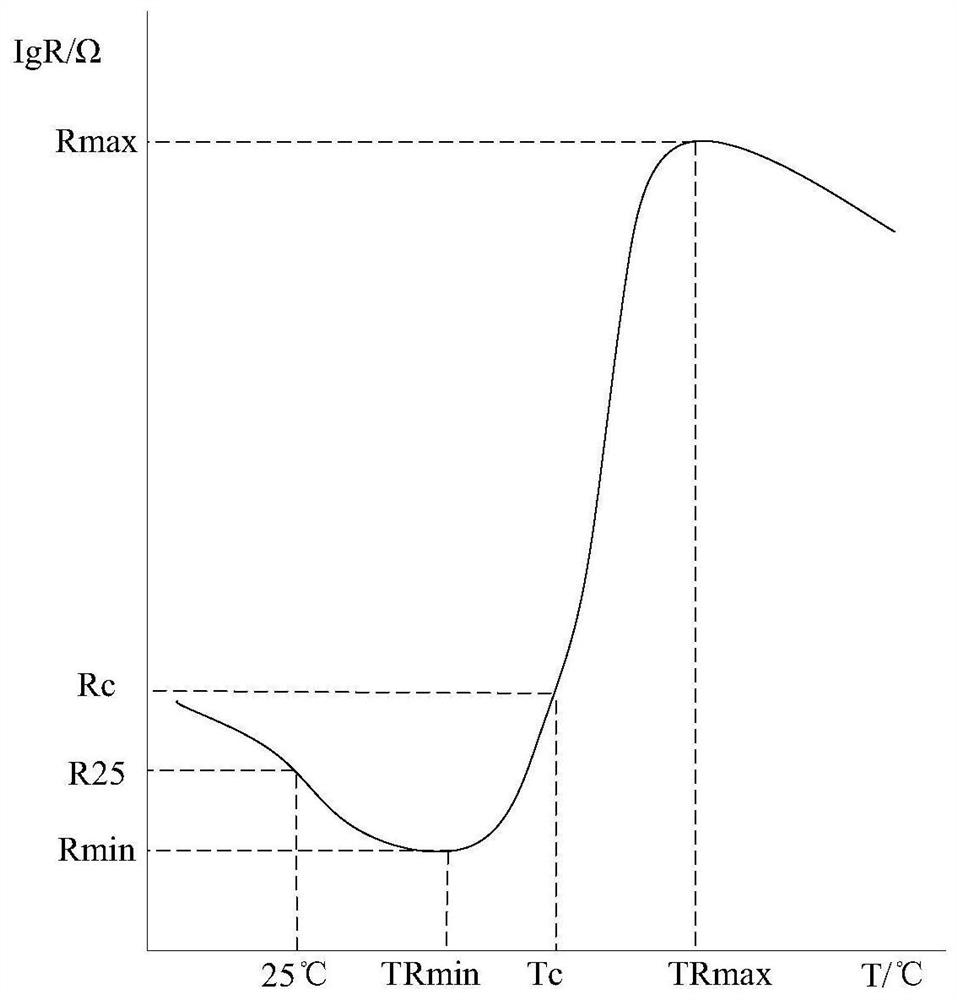

[0071] Optionally, the mapping table may include a first temperature mapping area and a second temperature mapping area; wherein, the temperature value contained in the first temperature mapping area is smaller than the temperature value contained in the second temperature mapping area;

[0072] The main control unit 1 is also used to detect the impedance of the second heating device multiple times according to the preset time interval; when the detected multiple impedances decrease successively, acquire the last detected impedance, and The impedance is compared with the first temperature mapping area to obtain the temperature of the second heating device; when the detected multiple impedances increase sequentially, the last detected impedance is compared with the second temperature mapping area to obtain the second The temperature of the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com