Method for producing 20 tons of molded pulp products per day

A technology of pulp molding and production methods, applied in the direction of non-woody plant/crop pulp, papermaking, textiles and papermaking, which can solve the problems of small scale and achieve the effect of improving smoothness, good durability and increasing whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

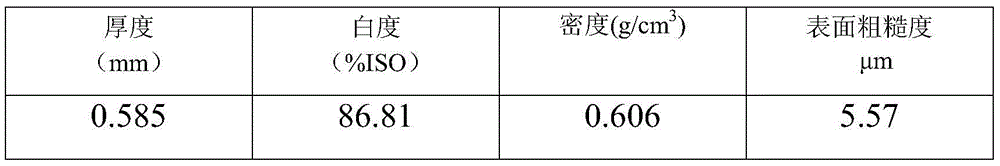

Embodiment 1

[0040] The production method of daily output 20 tons of pulp molded products, comprises the steps:

[0041] (1) Mold core preparation: Design and manufacture the corresponding mold core according to the product requirements and shape, and then install the mold core on the pulp molding automatic machine. The diameter of the dehydration holes is 1 mm, and the distance between the holes is 10 mm.

[0042] (2) Pulping: first put bamboo pulp board, clean white paper scraps, and bagasse pulp into the hydraulic pulper according to the mass ratio of 8:1:1, and add water repellent and 2% dry pulp quality 5% wet strength agent, then stir it and break it up.

[0043] (3) Deflashing: transport the crushed pulp to the deflaking unit through the pump for deflaking. The concentration of defoaming is 10%.

[0044] (4) Beating: pump the pulp made above into a beater for beating. The beating concentration is 5%, and the beating degree is 20°SR.

[0045] (5) Pulp blending: pump the prepared...

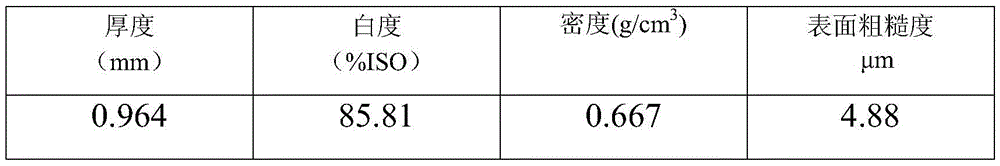

Embodiment 2

[0053] The production method of daily output 20 tons of pulp molded mobile phone box products is characterized in that comprising the steps:

[0054] (1) Mold core preparation: Design and manufacture the corresponding mold core according to the product requirements and shape, and then install the mold core on the pulp molding automatic machine. The diameter of the dehydration holes is 1.5mm, and the distance between the holes is 15mm.

[0055](2) Pulping: first put bamboo pulp board, clean white paper scraps, and bagasse pulp into the hydraulic pulper according to the mass ratio of 6:3:1, and add water repellent and 3% dry pulp quality 7% wet strength agent, then stir it up and disintegrate. The added amount is the mass ratio of the chemical reagent to the dry pulp.

[0056] (3) Deflashing: transport the crushed pulp to the deflaking unit through the pump for deflaking. The concentration of defoaming is 15%.

[0057] (4) Beating: pump the pulp made above into a beater for ...

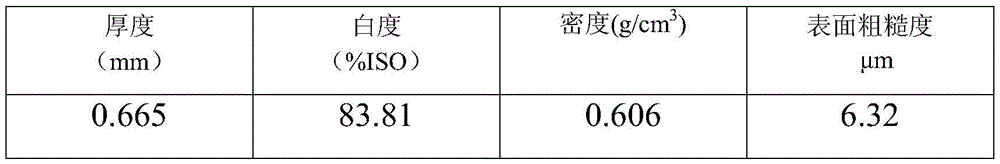

Embodiment 3

[0066] The production method of 20 tons of pulp molded wine box products per day is characterized in that comprising the steps:

[0067] (1) Mold core preparation: Design and manufacture the corresponding mold core according to the product requirements and shape, and then install the mold core on the pulp molding automatic machine. The diameter of the dehydration holes is 2mm, and the distance between the holes is 20mm.

[0068] (2) Pulping: first put the bamboo pulp board, clean white paper scraps, and bagasse pulp into the hydraulic pulper according to the mass ratio of 7:2:1, and add 4% of the dry pulp quality waterproofing agent and 9% wet strength agent, then stir it up and disintegrate. The added amount is the mass ratio of the chemical reagent to the dry pulp.

[0069] (3) Deflashing: transport the crushed pulp to the deflaking unit through the pump for deflaking. The concentration of defoaming is 13%.

[0070] (4) Beating: pump the pulp made above into a beater for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com