New process and a dissolving pulp manufactured by the process

A dissolving pulp and process technology, applied in the field of pulp manufacturing, can solve the problems of high cost, low total yield of dissolving pulp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

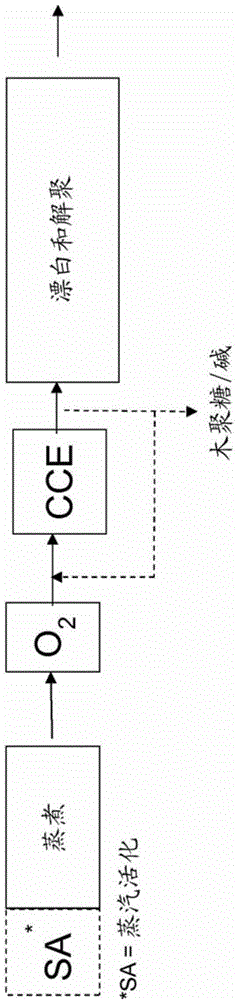

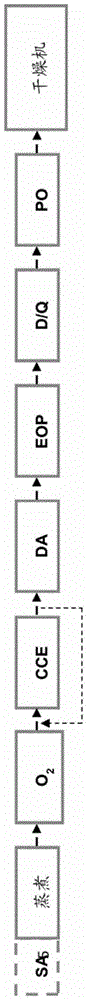

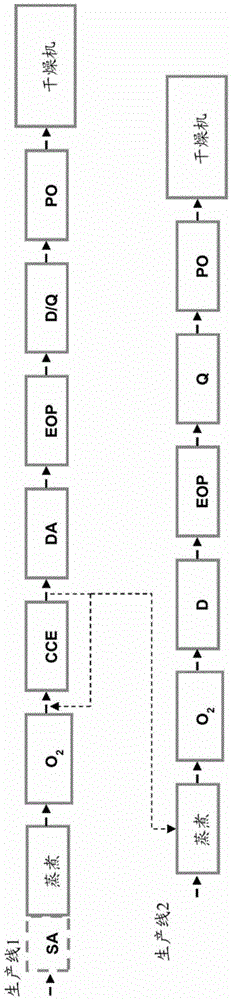

Method used

Image

Examples

Embodiment 1

[0134] Silver birch wood containing 25% xylan was cooked to pulp with a kappa number of 17 in an industrial cooking system according to the rapid displacement heating (RHD) process. The cooking temperature was 160°C, the H-factor was 350, and the residual alkali was 10 g / l. After cooking, the slurry is sieved before oxygen delignification in a two-step industrial process. The temperature in the first reactor was 85°C and the temperature in the second reactor was 102°C. The total alkali dosage is 23kg / ADT, the total oxygen dosage is 15kg / ADT, and the magnesium sulfate dosage is 3kg / ADT. After oxygen delignification, the pulp samples are removed in the wash press and washed again for further processing of the pulp in the laboratory. After oxygen delignification, the pulp had a kappa number of 9.3, a brightness of 59.8% ISO and a viscosity of 1008 m / g.

[0135] The slurry was then treated with technical white liquor of high ionic strength at a consistency of 10% and an effecti...

Embodiment 2

[0142] Embodiment 2 pulp mill technology

[0143] In this example, 4 groups of cooking pots are used, and each group of cooking pots occupies an area of 325m 3 Kraft pulp mills are used. The raw material consists of 93% birch and 7% other hardwoods, mainly poplar. Chips were steamed to a P-factor of 100, and activation was terminated by adding white liquor to the bottom of the digester, followed by a mixture of white and black liquor until a cooking liquor:wood-based material ratio of 3.7:1 was reached. At 160° C., a cooking step was carried out with solution circulation until an H-factor of 400 was reached. Typical properties of the cooked pulp are: Viscosity: 1100 m / g, Brightness: 45% ISO, Kappa Number: 13.

[0144] Oxygen delignification was carried out in a two-step reactor using a total oxygen amount of 23 kg / ADT without any additional amount of alkali. 1kg MgSO 4 The amount of / ADT was used to minimize degradation reactions. In two steps, the temperature was 86°C...

Embodiment 3

[0152] Embodiment 3 and the comparison of commercialization dissolving pulp

[0153] Different commercial pulps (pulp and dissolving pulp) were collected and analyzed using L&W fiber tester and CP-MAS 13 C NMR spectroscopy [Wollboldt et al., 2010 (Wood Sci. Technol. 44:533-546)] for analysis. The unique properties of dissolving pulp produced using the methods defined herein are illustrated by the measured data shown in Tables 3 and 4 below.

[0154] Table 3 Data obtained from fiber size and WRV-measurement analysis by L&W fiber tester

[0155]

[0156]

[0157] 1 Birch Paper Kraft Pulp

[0158] 2 Eucalyptus kraft pulp

[0159] 3 Birch dissolving pulp made according to Example 2

[0160] 4 Commercial prehydrolyzed eucalyptus kraft dissolving pulp

[0161] 5 commercial beech sulfite dissolving pulp

[0162] Table 4 from using CP-MAS 13 The data obtained by C NMR spectroscopic analysis

[0163]

[0164] 1 Birch Paper Kraft Pulp

[0165] 2 Birch dissolving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brightness | aaaaa | aaaaa |

| Brightness | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com