Waste heat utilization device for air compressor

A technology of air compressors and heating water tanks, applied in space heating and ventilation, application, heating methods, etc., can solve problems affecting the normal operation of the machine, adverse effects, waste of resources, etc., to achieve repeated recycling and improve humidification Effect, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

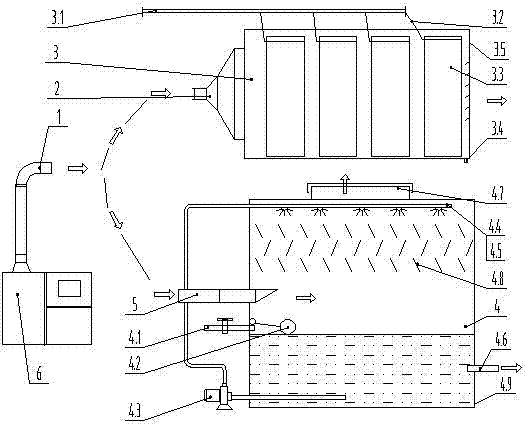

[0020] The air compressor waste heat utilization device shown in the accompanying drawings includes an air compressor 6, a humidifier 3, and a heating water tank 4; The hot air inlet 2 of the humidifier and the hot air inlet 5 of the heating water tank; the waste hot air outlet 1 of the air compressor communicates with the hot air inlet 2 of the humidifier and the hot air inlet 5 of the heating water tank respectively.

[0021] The humidifier 3 includes a housing 3.5, a water supply pipe 3.1, a fine water pipe 3.2, a wet curtain 3.3, and a humidifier hot air inlet 2; several wet curtains 3.3 are suspended in the housing 3.5. Made of filter material; the fine water pipe 3.2 is placed on the upper part of the wet curtain 3.3 and connected to the water supply pipe 3.1; a plurality of small holes are evenly distributed on the thin water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com