Harmless waste resin treating technology

A technology of harmless treatment and waste resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

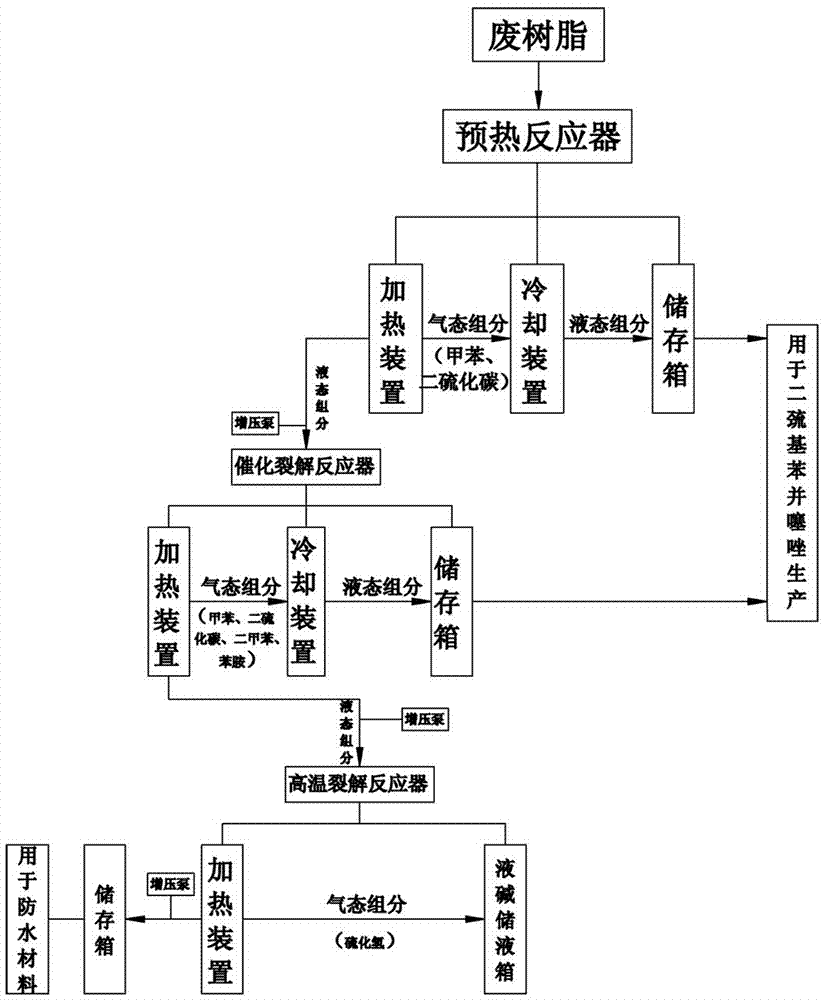

Image

Examples

Embodiment 1

[0017] Embodiment 1: a kind of harmless treatment process of waste resin, comprises the following steps:

[0018] (1) Preheating treatment: collect the waste resin produced during the production process of dimercaptobenzothiazole, and put an appropriate amount into the preheating reactor. The preheating reactor is cylindrical, and the bottom and top of the preheating reactor are A heating device and a cooling device are respectively provided. The heating device is an explosion-proof electric heater, and the cooling device is a gas trap. The heating device preheats and melts the waste resin. The temperature of the reactor is controlled at 50-70°C for 3 hours. -5 hours, obtain the waste resin of liquid, for subsequent use; Avoid the volatile matter that waste resin produces in heating process by arranging cooling device and escape, volatile matter mainly is toluene, xylene and carbon disulfide, described toluene, xylene and carbon disulfide The proportion of the amount of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com