Treatment method of industrial waste salt

A treatment method and technology of industrial waste salt, applied in the field of environmental pollution control, can solve problems such as high energy consumption, unexplained treatment of waste residue, and inability to send waste salt to landfill, etc., to achieve simple operation and reduce landfill level and risk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

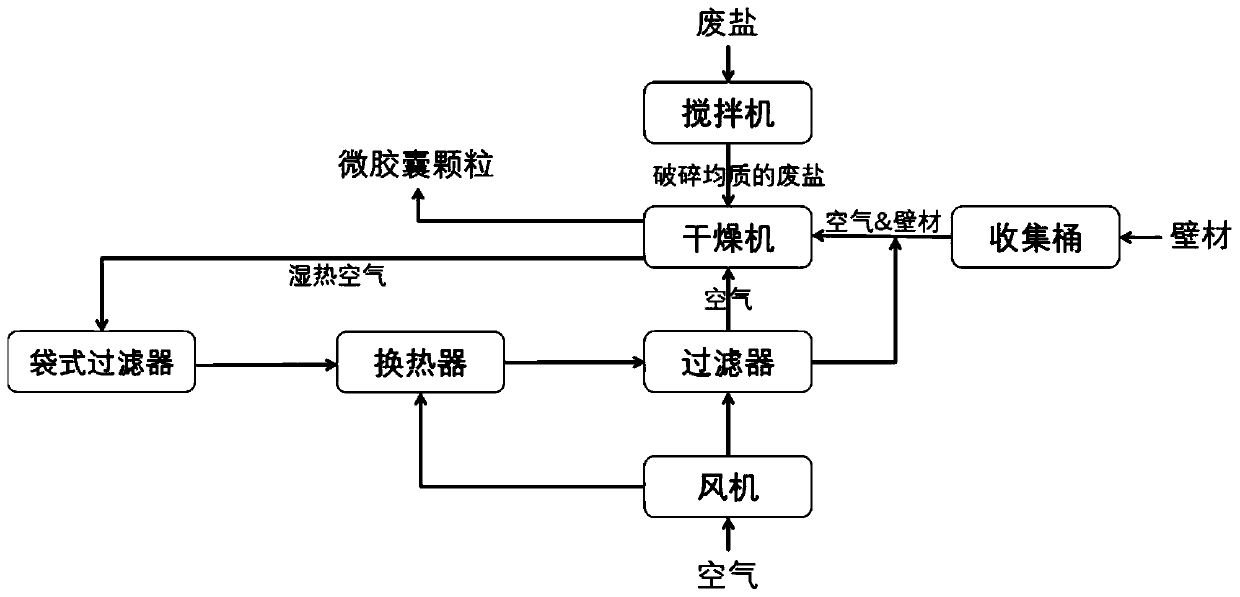

[0032] In this example, the industrial waste salt produced by a certain chemical factory is taken. Its initial state is uneven lumpy, yellowish, and contains a large amount of organic matter. The amount of waste salt to be processed each time is 1000g.

[0033] Put 1000g of industrial waste salt into the hopper of the mixer and stir, so that the waste salt becomes a broken and homogeneous state and the particle diameter of the waste salt is ≤ 1mm. The waste salt is located at the bottom of the fluidized granulation dryer.

[0034] The compressed air is fed into the preheated heat exchanger through the fan, and the heated air is sent to the boiling granulation dryer after being filtered by the filter, and flows upward from the bottom of the boiling granulation dryer. By adjusting the size of the air volume, the upward flowing air drives the waste salt into a suspension state, and the air forms an airlift circulation flow inside the fluidized granulation dryer.

[0035] Weigh 2...

Embodiment 2

[0037] In this example, the industrial waste salt produced by a pesticide production enterprise is taken. Its initial state is uneven, blocky, yellowish, and contains a large amount of organic matter. The amount of waste salt to be processed each time is 1000g.

[0038] Put 1000g of industrial waste salt into the hopper of the mixer and stir, so that the waste salt becomes a broken and homogeneous state and the particle diameter of the waste salt is ≤ 1mm. The waste salt is located at the bottom of the fluidized granulation dryer.

[0039] The compressed air is fed into the preheated heat exchanger through the fan, and the heated air is sent to the boiling granulation dryer after being filtered by the filter, and flows upward from the bottom of the boiling granulation dryer. By adjusting the size of the air volume, the upward flowing air drives the waste salt into a suspension state, and the air forms an airlift circulation flow inside the fluidized granulation dryer.

[0040...

Embodiment 3

[0042] In this embodiment, the industrial waste salt produced by a certain pharmaceutical company is taken, and its initial state is inhomogeneous lumps containing organic matter, and the amount of waste salt to be processed each time is 1500 g.

[0043] Put 1500g of industrial waste salt into the hopper of the mixer and stir, so that the waste salt becomes a broken and homogeneous state and the particle diameter of the waste salt is ≤ 1mm. The waste salt is located at the bottom of the fluidized granulation dryer.

[0044] The compressed air is fed into the preheated heat exchanger through the fan, and the heated air is sent to the boiling granulation dryer after being filtered by the filter, and flows upward from the bottom of the boiling granulation dryer. By adjusting the size of the air volume, the upward flowing air drives the waste salt into a suspension state, and the air forms an airlift circulation flow inside the fluidized granulation dryer.

[0045] Weigh 215g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com