Circulating synchronous straw enzymatic hydrolysis fermentation fuel ethanol reactor and reaction method thereof

A circulating reactor and synchronous enzymatic hydrolysis technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, fermentation, etc., to achieve the effect of reducing dosage, saving production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

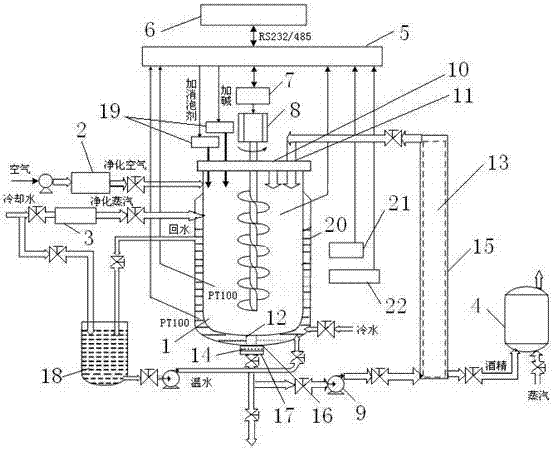

Image

Examples

Embodiment 1

[0043] (1) Pulverization: After cleaning the fresh sorghum straw, cut it with a shredding machine or pulverize it with a hammer mill, sieve it into 40mm straw powder, and control the moisture content below 55%.

[0044] (2) Biological pretreatment: sorghum straw powder is treated by white rot fungi for lignin degradation.

[0045] (3) Sterilization: put the sorghum straw powder into the circulating integrated reactor for high temperature sterilization, 121 ℃, 30min sterilization treatment.

[0046] (4) Double-enzyme saccharification and fermentation: The mixed solution of cellulase, xylanase and Saccharomyces cerevisiae is sprayed downward from the top of the fermenter, and the amount of cellulase whose activity is 1000IU / g is 1.5% of the weight of the straw. , the amount of Saccharomyces cerevisiae with an activity of 6 billion / g is 1% of the weight of the straw, the amount of water is 2.5 times the weight of the straw powder, the enzymatic hydrolysis and fermentation temper...

Embodiment 2

[0053] (1) Pulverization: After cleaning the fresh corn stalks, cut them with a shredding machine or pulverize them with a hammer mill, sieve them into 30mm straw powder, and control the moisture content at 50%.

[0054] (2) Biological pretreatment: corn stalk powder is subjected to lignin degradation treatment by white rot fungi.

[0055] (3) Sterilization: put the corn stalk powder into the circulating integrated reactor for high temperature sterilization, 121 ℃, 30min sterilization treatment.

[0056] (4) Double-enzyme saccharification and fermentation: the mixed solution of cellulase, xylanase and Saccharomyces cerevisiae is sprayed downward from the top of the fermenter, and the addition amount of cellulase with an activity of 1000 IU / g is 2% of the weight of the straw , the amount of Saccharomyces cerevisiae with an activity of 8 billion / g is 0.8% of the weight of the straw, the amount of water is 2.5 times the weight of the straw powder, the enzymatic hydrolysis and fer...

Embodiment 3

[0063] (1) Pulverization: After cleaning the fresh rice straw, cut it with a shredding machine or pulverize it with a hammer mill, sieve it into 30mm straw powder, and control the moisture content at 53%.

[0064] (2) Biological pretreatment: The rice straw powder is subjected to lignin degradation treatment by white rot fungi.

[0065] (3) Sterilization: The rice straw powder was put into a circulating integrated reactor for high temperature sterilization, 121℃, 30min sterilization treatment.

[0066] (4) Double-enzyme saccharification and fermentation: the mixed solution of cellulase, xylanase and Saccharomyces cerevisiae is sprayed downward from the top of the fermenter, and the addition amount of cellulase with an activity of 1000 IU / g is 2% of the weight of the straw , the amount of Saccharomyces cerevisiae with an activity of 8 billion / g is 1% of the weight of the straw, the amount of water is 2 times the weight of the straw powder, the enzymatic hydrolysis and fermenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com